Chinese Hot-dip Zinc Coating Steel Building Roof Walls

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 56 m.t.

- Supply Capability:

- 22222 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

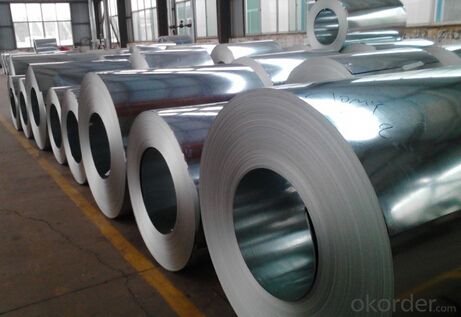

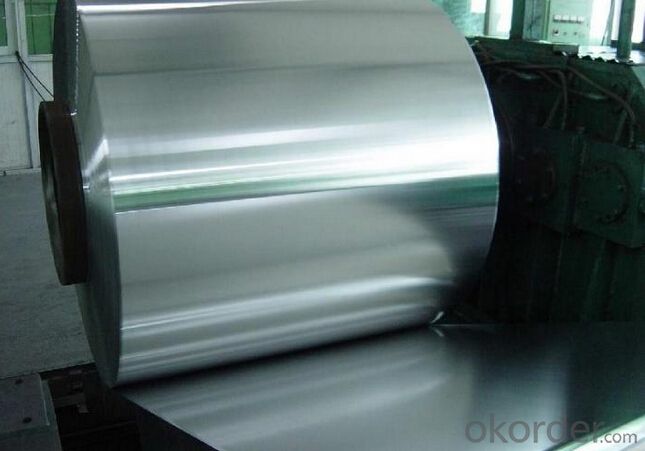

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

Processability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: Are steel strips expensive?

- Yes, steel strips can be quite expensive due to their production process, quality, and market demand. The cost can vary depending on factors such as size, thickness, grade, and quantity required.

- Q: How do steel strips compare to other materials in terms of strength and durability?

- Steel strips are known for their exceptional strength and durability, making them highly desirable in various applications. When compared to other materials, such as aluminum, plastic, or wood, steel strips generally outperform in terms of both strength and durability. Steel has a high tensile strength, meaning it can withstand large amounts of stretching or pulling forces without breaking or deforming. This makes steel strips ideal for applications requiring structural integrity, such as in construction, automotive, or aerospace industries. In comparison, materials like aluminum or plastic tend to have lower tensile strengths, making them less suitable for heavy-duty applications. Additionally, steel strips exhibit excellent durability, meaning they can withstand wear, impact, and harsh environmental conditions without significant damage or degradation. This durability is especially valuable in industries where materials face constant stress or exposure to extreme temperatures, moisture, or corrosive substances. While other materials may offer some level of durability, steel strips stand out due to their superior resistance against wear and environmental factors. Moreover, steel strips have a long lifespan, which contributes to their overall durability. They are less likely to crack, warp, or decay over time, unlike materials such as wood or plastic. This longevity makes steel strips a cost-effective choice in applications where replacements or repairs would be frequent and costly. In summary, steel strips surpass other materials in terms of strength and durability. Their high tensile strength and exceptional resistance to wear and environmental factors make them the preferred choice for various industries. Whether it is for structural support, heavy-duty applications, or long-lasting durability, steel strips consistently prove their superiority over alternative materials.

- Q: How do steel strips contribute to the circular economy?

- Steel strips contribute to the circular economy by enabling the recycling and reuse of steel materials. When steel strips are used in various industries, such as automotive or construction, they can be easily collected, processed, and transformed into new steel products. This reduces the need for extracting and manufacturing new steel, conserving natural resources and minimizing waste generation. Additionally, steel strips are durable and can be recycled multiple times without losing their strength, making them an ideal material for a sustainable circular economy.

- Q: How are steel strips tested for edge condition?

- Steel strips are tested for edge condition by conducting visual inspections, measuring the edge burr, and checking for any cracks or deformations. Additionally, various mechanical tests such as bending, flattening, and hardness tests may be performed to ensure the desired edge quality of the steel strips.

- Q: How are steel strips priced?

- Several factors determine the pricing of steel strips. The cost of raw materials, such as iron ore, coal, and other essential elements, is the primary factor. Moreover, the pricing is influenced by the manufacturing process, including labor and energy costs. The dynamics of market demand and supply also play a vital role. When demand is high and supply is limited, prices typically rise, and the opposite is true as well. Transportation costs, import and export duties, and currency exchange rates are other factors that can have an impact on the final price of steel strips. Ultimately, the pricing of steel strips is determined by a combination of these factors and market forces.

- Q: Are steel strips suitable for the manufacturing of defense equipment?

- Yes, steel strips are suitable for the manufacturing of defense equipment. Steel strips offer high strength, durability, and resistance to corrosion, making them ideal for the production of various defense equipment such as armored vehicles, weapons, and aircraft components. Additionally, steel strips can be easily formed and molded into different shapes, enabling the creation of complex defense equipment designs.

- Q: How are steel strips processed for load-bearing capacity?

- Steel strips are processed for load-bearing capacity through a series of manufacturing and treatment processes. The first step in enhancing load-bearing capacity is the selection of the appropriate grade of steel. Different grades of steel have varying mechanical properties, such as yield strength and tensile strength, which directly impact load-bearing capacity. Higher strength grades, such as high-strength low-alloy (HSLA) or advanced high-strength steel (AHSS), are typically chosen for applications requiring greater load-bearing capacity. Once the steel grade is determined, the steel strips undergo a series of manufacturing processes. The strips are usually hot-rolled or cold-rolled to achieve the desired thickness and shape. Hot-rolling involves heating the steel above its recrystallization temperature and passing it through a series of rollers to reduce thickness and shape it into a strip. Cold-rolling, on the other hand, involves passing the steel through rollers at room temperature, resulting in a smoother finish and tighter tolerances. After the initial rolling process, the steel strips may undergo further treatments to enhance their load-bearing capacity. One common treatment is heat treatment, which involves heating the steel to a specific temperature and then rapidly cooling it to alter its microstructure. This process can increase the strength and hardness of the steel, improving its load-bearing capacity. Other treatments may include surface coatings or galvanization to protect the steel from corrosion, which can weaken its load-bearing capacity over time. Coatings such as zinc or epoxy can provide an extra layer of protection against environmental factors that may compromise the integrity of the steel strips. In summary, steel strips are processed for load-bearing capacity by selecting the appropriate grade of steel, followed by manufacturing processes such as hot-rolling or cold-rolling. Additional treatments like heat treatment and surface coatings may be applied to further enhance the load-bearing capacity and protect the steel from corrosion.

- Q: How are steel strips coated with a metallic coating?

- Through the process of hot-dip galvanizing, steel strips can be coated with a metallic coating. The first step in this process involves cleaning the steel strips to remove impurities. Next, the strips are immersed in a bath of molten zinc at temperatures around 450°C (840°F). Careful attention is given to ensure that the entire surface of the strips is uniformly coated as they are passed through the zinc bath. While the steel strips are submerged in the molten zinc, a metallurgical reaction occurs between the zinc and the steel. This reaction results in the formation of a protective coating consisting of zinc-iron alloy layers on the steel's surface. The thickness of this coating can be adjusted by controlling the speed at which the strips are passed through the zinc bath. Hot-dip galvanizing is a widely used method for coating steel strips due to its excellent corrosion protection capabilities. The zinc coating acts as a barrier, preventing the steel from coming into contact with the surrounding environment and thus inhibiting the formation of rust and other forms of corrosion. Additionally, the zinc coating is sacrificial, meaning that if it becomes damaged, the zinc will corrode before the steel, further extending the lifespan of the steel strips. By undergoing this process of being coated with a metallic coating, steel strips gain increased durability and resistance to corrosion. As a result, they are well-suited for a wide range of applications in industries such as construction, automotive, and electrical.

- Q: Can steel strips be bent or formed?

- Yes, steel strips can be bent or formed into various shapes and configurations.

- Q: What are the thickness options for steel strips?

- The thickness options for steel strips can vary depending on the specific requirements and applications. Generally, steel strips can be found in a range of thicknesses from thin gauges, such as 0.001 inches (0.0254 mm), to thicker gauges, such as 0.25 inches (6.35 mm) or more. The thickness chosen will depend on factors like the intended use, strength requirements, and manufacturing capabilities.

Send your message to us

Chinese Hot-dip Zinc Coating Steel Building Roof Walls

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 56 m.t.

- Supply Capability:

- 22222 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords