Z150 Zinc Coating Steel Building Roof Walls Steel Coil ASTM 615-009

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 kg/m²

- Supply Capability:

- 11 kg/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for Community portal – Bulletin board, projects, resources and activities covering a wide range of Wikipedia areas.

Help desk – Ask questions about using Wikipedia.

Local embassy – For Wikipedia-related communication in languages other than English.

Reference desk – Serving as virtual librarians, Wikipedia volunteers tackle your questions on a wide range of subjects.

Site news – Announcements, updates, articles and press releases on Wikipedia and the Wikimedia Foundation.

Village pump – For discussions about Wikipedia itself, including areas for technical issues and policies.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

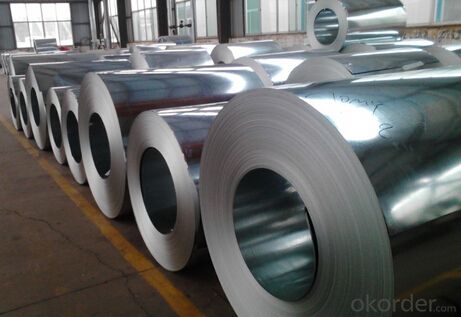

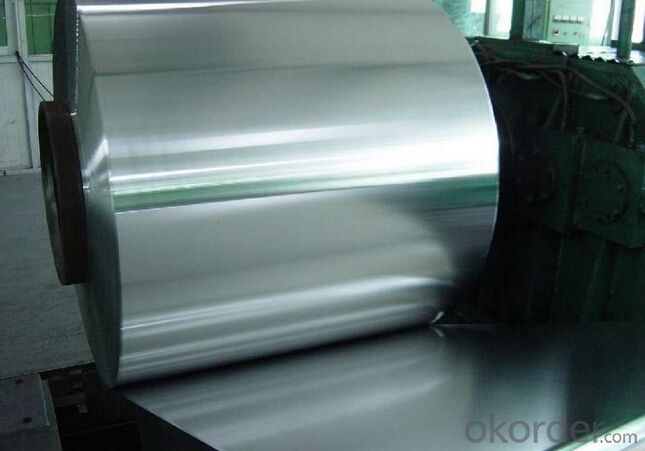

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

Processability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: What are the main applications of steel strips?

- Steel strips have a wide range of applications in various industries due to their exceptional properties and versatility. Some of the main applications of steel strips include: 1. Automotive Industry: Steel strips are extensively used in the automotive sector for the manufacturing of various components such as springs, suspension systems, brackets, reinforcements, and body panels. The high strength, durability, and formability of steel strips make them ideal for enhancing the structural integrity and safety of vehicles. 2. Construction Industry: Steel strips find significant applications in the construction industry for a multitude of purposes. They are commonly used in the fabrication of structural members like beams, columns, and trusses, as well as in the production of roofing, cladding, and fencing materials. Steel strips ensure the strength, stability, and longevity of structures, making them an essential material in construction projects. 3. Electrical Industry: Steel strips are used extensively in the electrical industry for the manufacturing of electrical transformers and motors. Due to their magnetic properties, steel strips are ideal for creating efficient and reliable electromagnetic circuits, enabling the efficient transmission and transformation of electrical energy. 4. Packaging Industry: Steel strips are employed in the packaging industry for the production of metal packaging materials such as cans, drums, and containers. The durability, corrosion resistance, and ease of forming of steel strips make them suitable for protecting and preserving a wide range of goods, including food and beverages, chemicals, and other perishable or sensitive products. 5. Manufacturing Industry: Steel strips are used in various manufacturing processes, including stamping, forming, and fabrication. They are commonly utilized in the production of appliances, furniture, machinery, and equipment due to their high strength, ductility, and ability to be shaped into complex geometries. 6. Aerospace Industry: Steel strips are utilized in the aerospace industry for the manufacturing of aircraft components and structures. Their exceptional strength-to-weight ratio, corrosion resistance, and heat resistance make them suitable for applications that require high-performance materials, such as aircraft frames, landing gears, and engine components. Overall, the main applications of steel strips span across multiple industries, including automotive, construction, electrical, packaging, manufacturing, and aerospace. The unique combination of strength, durability, formability, and magnetic properties make steel strips an indispensable material in various sectors, contributing to the advancement and progress of modern technology and infrastructure.

- Q: How are steel strips used in the manufacturing of conveyor systems?

- Steel strips are used in the manufacturing of conveyor systems to provide support and stability. These strips are often used as the base or frame of the conveyor, ensuring durability and strength to handle heavy loads and continuous movement. Additionally, steel strips may be used as guides or rails to keep the conveyor belt aligned and prevent any deviation. Overall, steel strips play a crucial role in enhancing the performance and reliability of conveyor systems in various industries.

- Q: How do steel strips contribute to product aesthetics in various applications?

- The utilization of steel strips in different applications can have a significant impact on the aesthetics of products. Firstly, the sleek and modern touch provided by steel strips can enhance the overall appearance of a product. The polished and sophisticated look achieved through the smooth and reflective surface of steel is visually appealing to customers. Secondly, the manipulation and formation of steel strips into various shapes and patterns allow for greater design flexibility. This versatility enables manufacturers to create unique and eye-catching designs that differentiate their products from competitors. Steel strips can be customized to meet specific aesthetic requirements, whether for decorative purposes or functional elements. Additionally, the aesthetics of a product can be further enhanced by coating or treating steel strips with different finishes. For instance, the application of colored finishes or protective coatings adds visual interest and durability. The range of available finishes allows designers to achieve different visual effects and textures, resulting in a distinctive and appealing appearance for products. Moreover, steel strips can be combined with other materials to create captivating contrasts or combinations in terms of colors, textures, and finishes. This integration leads to visually striking and harmonious designs that appeal to the senses and emotions of consumers. Lastly, the durability and longevity of steel strips are crucial factors in product aesthetics. By utilizing steel strips, manufacturers can ensure that their products maintain their appearance and functionality over time, contributing to a positive perception of the product's aesthetics. Overall, steel strips offer a multitude of aesthetic possibilities in various applications. Their sleek appearance, design versatility, customizable finishes, compatibility with other materials, and durability all contribute to enhancing the overall aesthetics of products.

- Q: How are steel strips processed for surface plating?

- To ensure proper adhesion and a smooth finish, the surface plating of steel strips involves a series of steps. These steps typically include: 1. Thoroughly cleaning the steel strips to eliminate any surface contaminants like dirt, grease, or other substances. This is accomplished by employing a combination of chemical cleaning agents and mechanical scrubbing. 2. Treating the cleaned steel strips to prepare their surface for plating. This can involve various techniques such as pickling, acid etching, or mechanical roughening. The objective is to create a roughened surface that promotes better adhesion of the plating material. 3. Immersing the prepared steel strips in an electrolyte bath containing the desired plating material. An electric current is then applied to the bath, causing the plating material to adhere to the steel strips. The plating material can be zinc, nickel, chromium, cadmium, or other metals depending on the desired properties and appearance. 4. Subjecting the electroplated steel strips to additional treatments to enhance the properties of the plating. These treatments may include heat treatment, passivation, or the application of a protective coating. These steps contribute to improving the plating's durability, corrosion resistance, and aesthetic appearance. 5. Implementing quality control measures throughout the entire process to ensure the plating meets the required specifications. Visual inspection, thickness measurement, adhesion tests, and other testing methods are employed to guarantee high-quality plating that meets the desired standards. By following these steps, steel strips can undergo effective surface plating, resulting in enhanced durability, corrosion resistance, and an appealing finish.

- Q: What are the different welding methods used for steel strips?

- Some common welding methods used for steel strips include MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas) welding, and spot welding. MIG welding is a popular choice for its speed and versatility, while TIG welding offers precise control and high-quality welds. Spot welding is commonly used for joining steel strips by applying heat and pressure at specific points.

- Q: How are steel strips used in the production of metal handrails?

- Steel strips are used in the production of metal handrails to provide structural strength and stability. They are typically shaped and welded together to form the framework of the handrail, ensuring durability and safety.

- Q: Can steel strips be used for making electrical connectors in power distribution systems?

- Electrical connectors in power distribution systems can be made using steel strips. This choice offers several advantages. Firstly, steel is a highly conductive material, making it appropriate for carrying electrical current. Its low resistance ensures minimal power loss during transmission and distribution. Steel also possesses good mechanical properties, enabling it to withstand the stresses and strains experienced in power distribution systems. Moreover, steel strips are easily moldable into different shapes and sizes, making them versatile for designing various types of connectors. They can be bent, punched, or welded to create specific connection points for electrical cables. Furthermore, steel strips can be coated with tin or nickel to enhance their corrosion resistance and electrical conductivity. Additionally, steel is a durable and long-lasting material that can endure harsh environmental conditions and provide reliable electrical connections over an extended period. This durability is crucial in power distribution systems, where connectors must maintain their integrity and conductivity under high voltage and current levels. However, it is important to note that steel strips may not be suitable for all types of electrical connectors. In certain applications where higher electrical conductivity or specific mechanical properties are required, materials such as copper or aluminum may be preferred. The choice of material for electrical connectors depends on various factors, including the specific requirements of the power distribution system, cost considerations, and industry standards.

- Q: Are steel strips magnetic?

- Yes, steel strips are magnetic as they are made primarily of iron, which is a ferromagnetic material.

- Q: Are steel strips suitable for the production of roofing materials?

- Yes, steel strips are suitable for the production of roofing materials. Steel strips are strong, durable, and resistant to various weather conditions, making them ideal for protecting buildings from the elements. Additionally, steel strips can be easily shaped and installed, providing a reliable and long-lasting solution for roofing applications.

- Q: Can steel strips be used in the production of electronics?

- Yes, steel strips can be used in the production of electronics. They are often used as a base material for circuit boards and as a structural component in electronic devices due to their strength, durability, and ability to dissipate heat effectively.

Send your message to us

Z150 Zinc Coating Steel Building Roof Walls Steel Coil ASTM 615-009

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 kg/m²

- Supply Capability:

- 11 kg/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords