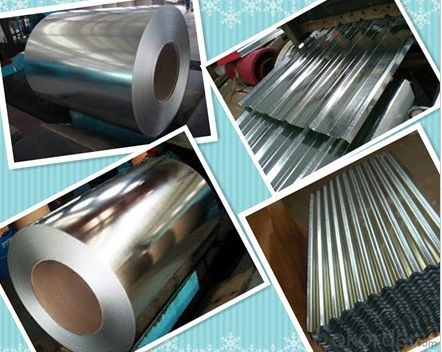

Hot-Dipped Corrugated Metal Roofing Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Brief Introduction

Hot-Dipped Corrugated Metal Roofing Sheet

--- Corrosion resistance: Pre-coated steel offers excellent corrosion resistance achived through continuous hot DIP galvanization and corrosion resistant primer/polyester coating. Protection is achieved when zinc and steel are together in the presence of moisture; The zinc protects the steel by galvanic action

Product Features

. Traditional aesthetics outlook

. Suitable for new house or renovation.

. Less joints, watertight

. Long life service

. Tedun also provide relative ridge cap, fasteners and other accessories

Product Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

FAQ

How long will we receive the goods ?

45days after receiving workable L/C

how do you control the quality ?

we have our own quality control department ,we will arrange QC person to see the production line ,when goods finish ,before shipment ,our QC person will check the quality as per our test report request ,if the goods is ok ,then we issue the test report ,and we allow the goods shipping ,otherwise will not allow ship the goods.

- Q: Are steel sheets suitable for construction scaffolding?

- Yes, steel sheets are suitable for construction scaffolding. Steel is a strong and durable material that can provide the necessary support and stability required for scaffolding systems. It can withstand heavy loads and provide a secure platform for workers to perform their tasks safely. Additionally, steel sheets can be easily assembled, disassembled, and reused, making them a cost-effective choice for construction scaffolding.

- Q: What is the typical elongation of a steel sheet?

- The typical elongation of a steel sheet can vary depending on the specific grade and thickness of the sheet. However, as a general guideline, the typical elongation for a steel sheet can range from 20% to 40% before it reaches its breaking point.

- Q: What is the average lifespan of steel sheets used for roofing?

- The lifespan of steel sheets used for roofing can vary based on several factors. Nevertheless, high-quality steel roofing sheets are designed to be extremely durable and long-lasting. On average, these steel sheets can endure for 40 to 70 years or potentially even longer if properly maintained and cared for. The longevity of steel roofing sheets can be influenced by factors such as the steel type and thickness, the coating or finish quality, the climate and weather conditions in the area, and the level of maintenance. Conducting regular inspections, cleaning, and repairs as necessary can help extend the lifespan of the steel sheets and ensure their good condition for many years. It is always advisable to seek guidance from roofing professionals or manufacturers for specific guidelines and recommendations regarding the lifespan of steel sheets used for roofing in a particular context.

- Q: Can steel sheets be used in high-temperature applications?

- Yes, steel sheets can be used in high-temperature applications due to their excellent heat resistance properties. Steel sheets are commonly used in industries such as automotive, aerospace, and manufacturing where high temperatures are encountered.

- Q: Are the steel sheets suitable for marine environments?

- Yes, steel sheets are suitable for marine environments. Steel is a commonly used material in marine applications due to its high strength, durability, and corrosion resistance properties. Steel sheets are often coated with protective layers, such as galvanization or paint, to further enhance their resistance to corrosion from saltwater exposure. Additionally, steel sheets can be fabricated to meet specific requirements, such as thickness and size, making them versatile for various marine applications including shipbuilding, offshore structures, and marine equipment. Overall, steel sheets are a reliable and suitable choice for use in marine environments.

- Q: Can steel sheets be used in HVAC applications?

- Yes, steel sheets can be used in HVAC applications. Steel is a commonly used material in HVAC systems due to its durability, strength, and resistance to corrosion. Steel sheets are often utilized for ductwork fabrication, as they can withstand high temperatures and provide a rigid structure for air distribution.

- Q: How do steel sheets perform in low-temperature environments?

- Steel sheets perform well in low-temperature environments due to their exceptional strength, durability, and resistance to fracture. Unlike other materials, steel retains its mechanical properties even at extremely low temperatures, making it a reliable choice for various applications in cold climates or industries like construction, transportation, and energy.

- Q: Are steel sheets prone to warping or bending?

- Yes, steel sheets are prone to warping or bending under certain conditions. Factors such as temperature changes, excessive weight, or improper handling can cause steel sheets to warp or bend.

- Q: Can the steel sheets be used for storage racks or shelves?

- Yes, steel sheets can be used for storage racks or shelves as they provide durability, strength, and stability required for supporting heavy loads.

- Q: Can steel sheets be used for elevator doors?

- Yes, steel sheets can be used for elevator doors. Steel is a common material choice for elevator doors due to its strength, durability, and fire resistance properties. It provides a secure and aesthetically pleasing solution for elevator door construction.

Send your message to us

Hot-Dipped Corrugated Metal Roofing Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords