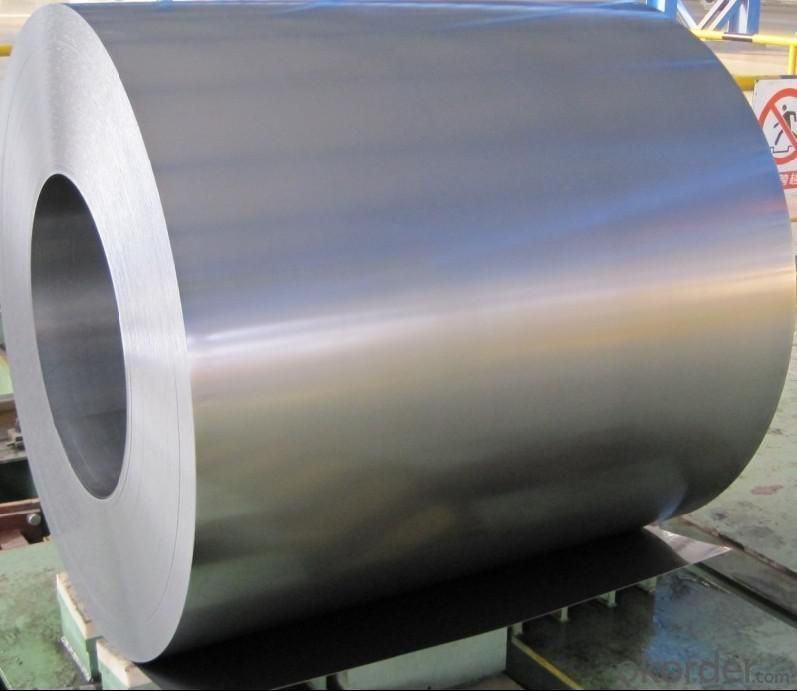

Hot-dip Zinc Coating Steel Coil Building Roof Walls

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls with Best Quality

Product Description:

Structure:

Hot-dip galvanized steel coils It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

Main Features:

• Excellent anticorrosive property

• High strength

• Good formability

Specifications:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Processability | Yield strength | Elongation % | 180°cold-bending | |

Common PV | - | 270-500 | d=0,intact,no zinc removal | |

Mechanical interlocking JY | - | 270-500 | d=0,intact,no zinc removal | |

Structure JG | >=240 | >=370 | d=0,intact,no zinc removal | |

Deep drawn SC | - | 270-380 | d=0,intact,no zinc removal | |

EDDQ SC | - | 270-380 | d=0,intact,no zinc removal |

- Q: im buying a new guitar,, it has a built in tuner and its semi acoustic (can be plugged into an amplifier) ,, im trying to choose which strings are better ,, steel or nylon..?

- That's not an option Guitars are designed for either nylon or steel strings. They aren't interchangeable. Putting steel strings on a guitar designed for nylon strings WILL destroy the guitar. If you've already picked out the guitar you want, then you've already made your decision about nylon or steel.

- Q: How are steel coils used in the production of oil and gas machinery?

- Steel coils are used in the production of oil and gas machinery as they provide essential structural support and reinforcement. These coils are typically formed into various components such as pipes, tubes, and casings, which are crucial for drilling, extraction, and transportation processes in the oil and gas industry. The strength and durability of steel coils ensure the reliability and longevity of the machinery, allowing for efficient and safe operations in the oil and gas sector.

- Q: How do steel coil manufacturers ensure employee safety?

- Employee safety in steel coil manufacturing is ensured through a range of measures and protocols aimed at preventing accidents, raising awareness, and providing appropriate training and protective equipment. Firstly, regular safety audits are conducted by manufacturers to identify and address potential hazards in the workplace. This involves inspecting machinery, equipment, and facilities to ensure they meet safety standards and are adequately maintained. To cultivate a safety-oriented culture, comprehensive training programs are implemented for all employees. These programs cover various topics such as proper equipment handling, safe practices for material handling, and emergency procedures. In addition, continuous training is provided to ensure employees remain updated on the latest safety protocols and best practices. Personal protective equipment (PPE) plays a crucial role in employee safety within steel coil manufacturing. Manufacturers ensure that employees are equipped with appropriate PPE, such as safety glasses, gloves, helmets, and protective clothing, and are trained in their correct usage. Regular checks are carried out to ensure that PPE is in good condition and promptly replaced when necessary. Manufacturers also employ engineering controls to minimize workplace risks. This may involve installing safety guards on machinery, implementing automated systems to reduce manual handling, and utilizing advanced technology for monitoring and controlling potential hazards. Regular maintenance and inspections are conducted to ensure that these controls function effectively. Moreover, a strong emphasis is placed on communication and employee involvement in safety programs. This includes encouraging employees to report hazards or near-miss incidents, conducting safety meetings and toolbox talks, and actively engaging employees in safety committees or teams. Manufacturers also foster a supportive environment where employees feel comfortable reporting safety concerns and suggesting improvements. Overall, steel coil manufacturers prioritize employee safety through a combination of measures, including regular safety audits, comprehensive training programs, provision of PPE, implementation of engineering controls, and the promotion of communication and employee involvement. These efforts contribute to the creation of a safe and secure working environment for all employees.

- Q: My company want to welding stainless steel, do not know to use what welding machine?

- There are many ways in welding stainless steel, such as coating manual welding,argon arc welding, pulsed argon arc welding, MIG, pulsed MIG, double pulsed MIG. Different welding ways own their merits and faults and adaptive working conditions. It is recommended to choose pulsed MIG, its molding very good and efficiency high, so it is mainstream application for stainless steel welding. Now many digital welding machines can supply these welding methods at the same time. And their welding effects is far better than traditional machines. Among them, FRONIUS’s TPS series and Nebula series are representitive products.

- Q: How are steel coils protected against moisture and humidity?

- There are several methods for protecting steel coils from moisture and humidity. One way is by applying a protective coating to the steel surface, which acts as a barrier against moisture. Coatings can be made of different materials, such as paint, zinc, or other substances that resist corrosion. In addition to coatings, steel coils are often wrapped in moisture-resistant materials like plastic or waxed paper. This wrapping provides an extra layer of protection during storage or transportation, preventing moisture from seeping into the coils. Furthermore, steel coils are typically stored in a controlled environment with regulated humidity levels. This helps to minimize the possibility of moisture condensation on the coil's surface. Storage facilities may also use dehumidifiers or other measures to control moisture and maintain optimal conditions. Lastly, proper handling and transport practices are essential for protecting steel coils from moisture and humidity. Special precautions are taken to avoid exposing the coils to rain or excessive humidity during loading, unloading, and transport. By implementing these protective measures, steel coils can be effectively safeguarded against moisture and humidity, reducing the risk of corrosion and preserving their quality and integrity.

- Q: What are the dimensions of steel coils used in bridge construction?

- The dimensions of steel coils used in bridge construction can vary depending on the specific requirements of the project. However, typical dimensions for steel coils used in bridge construction range from 0.5 to 2 inches in thickness and 24 to 72 inches in width.

- Q: What is the role of steel coils in the production of storage tanks?

- Steel coils are used in the production of storage tanks as they provide the necessary material for constructing the tank's shell. The coils are shaped and welded together to form the cylindrical structure, ensuring strength and durability. Additionally, the use of steel coils allows for customization, enabling the tanks to be built to specific sizes and capacities.

- Q: How are steel coils inspected for edge quality?

- Inspectors use a combination of visual inspection and non-destructive testing methods to assess the edge quality of steel coils. During visual inspection, trained inspectors carefully examine the entire length of the coils to detect visible defects like cracks, chips, or uneven edges. Non-destructive testing methods, including ultrasonic testing and magnetic particle inspection, are also utilized to uncover any hidden defects or imperfections in the edges of the steel coils. Ultrasonic testing employs high-frequency sound waves to identify internal flaws or discontinuities in the steel, while magnetic particle inspection utilizes magnetic fields and particles to detect surface or near-surface defects. Both visual inspection and non-destructive testing methods are vital in guaranteeing the quality of the steel coil edges. Manufacturers can identify and resolve any defects or imperfections by conducting these inspections, thereby ensuring that the coils meet the required quality standards.

- Q: How are steel coils inspected for flatness?

- Steel coils are inspected for flatness by using a variety of methods and techniques to ensure they meet the required standards. One common method is through visual inspection, where trained inspectors visually examine the surface of the coil for any signs of waviness or unevenness. They look for any visible defects such as waves, buckles, or twists that may affect the flatness of the coil. Another method used for inspecting flatness is through the use of specialized equipment such as flatness gauges or profilometers. These instruments measure the surface profile of the coil and provide detailed information about any deviations from the desired flatness. They can detect both local and overall flatness issues, allowing for a more accurate assessment of the coil's quality. In addition to visual and instrumental inspections, steel coils can also undergo physical tests to assess their flatness. One such test is the "drape" test, where the coil is draped over a flat surface and any noticeable gaps or unevenness are measured. This test provides a quick and practical way to identify any major flatness issues. Furthermore, computerized analysis and simulation techniques are becoming increasingly popular for inspecting the flatness of steel coils. These methods involve using advanced software to analyze the coil's surface data and generate detailed reports on its flatness characteristics. By comparing the actual surface profile with the desired specifications, these techniques provide a comprehensive assessment of the coil's flatness. Overall, inspecting steel coils for flatness involves a combination of visual inspection, specialized equipment, physical tests, and advanced analysis techniques. These methods ensure that the coils meet the required flatness standards, which is crucial for their successful use in various industries like automotive, construction, and manufacturing.

- Q: How are steel coils weighed?

- Steel coils are typically weighed using industrial weighing scales or load cells. These devices are capable of accurately measuring the weight of the coils, whether they are small or large in size. The coils are placed on the scale or load cells, and the weight is digitally displayed or recorded for further analysis or documentation.

Send your message to us

Hot-dip Zinc Coating Steel Coil Building Roof Walls

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords