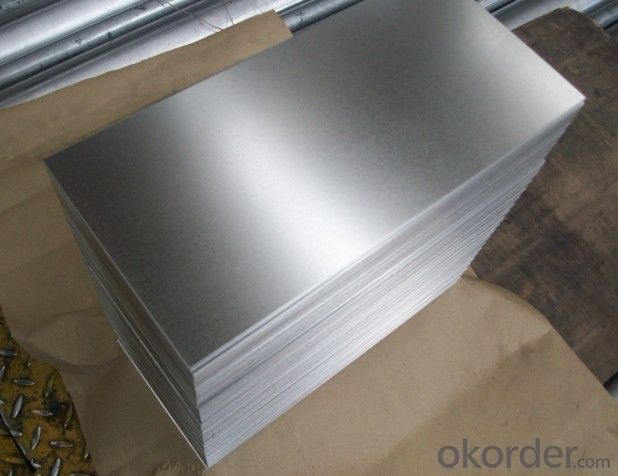

Hot-dip Zinc Coating Steel Sheets in Coils

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Sheets in Coils in Prime Quality and Best Price

Structure:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. 2.Main Features of the Galvanized Steel Coil:

Features:

• Base material for countless outdoor and industrial applications

• High corrosion resistance

• High strength

• Good formability

Specifications:

Operate Standard: ASTM A653M-04/JIS G3302/DIN EN10143/GBT 2518-2008

Grade : SGCD,SGCH, Q195,DX51D

Width:914-1250mm(914mm, 1215mm,1250mm,1000mm the most common)

Coil id:508mm/610mm

Coil weight: 4-10 MT(as required)

Zinc coating :40-180g( as required)

Surface: regular/mini/zero spangle, chromated, skin pass, dry etc.

Advantage of our product:

Firstly, our base material is of high quality, Their performance is in smooth and flat surface,no edge wave ,good flexibility.

Secondly, high quality zinc ingoats, 97.5% zinc,1.5% silicon,1% others, the same zinc coating measured by metal coating thickness or by zinc weight

Thirdly, high precision: Tolerance strictly according to ASTM or JISG standard even more rigid.

We have full stes of testing equipment(for t best, cupule,chromatism,salt spray resistance, etc) and professional engineers.

- Q: What is the maximum thickness of steel coils?

- The maximum thickness of steel coils can vary depending on the specific application and manufacturing process. However, in general, steel coils can have a maximum thickness ranging from a few millimeters to several centimeters. The thickness is typically determined by factors such as the intended use of the steel coils, the type of steel being used, and the capabilities of the manufacturing equipment.

- Q: Can steel coils be welded together?

- Yes, steel coils can be welded together. Welding is a common method used to join steel coils, where the edges of the coils are heated and fused together to create a continuous and strong joint.

- Q: I want to get a new knife but i cant decide if i wan a spyderco pacific salt or a cold steel ak47

- Given okorder / but always shop around and try Ebay...

- Q: What is the role of steel coils in the production of storage shelves?

- Steel coils play a crucial role in the production of storage shelves as they are used as the primary material to create the structural components of the shelves. These coils are flattened, cut, and formed into various shapes and sizes to construct the frames, supports, and shelves themselves. The durability and strength of steel coils ensure that the storage shelves can withstand heavy loads and provide long-lasting storage solutions.

- Q: Can steel coils be coated with luminescent materials?

- Yes, steel coils can be coated with luminescent materials.

- Q: What are the different types of steel coil treatments?

- Enhancing the properties and performance of steel coils involves various types of treatments. The treatments include: 1. Heat treatment known as annealing. It involves heating the steel coil to a specific temperature and gradually cooling it. This treatment alleviates internal stresses, enhances ductility, and boosts the overall strength of the coil. 2. Chemical treatment called pickling. It entails submerging the steel coil in an acid or chemical solution to eliminate impurities, scale, and rust from the surface. This treatment enhances the surface finish and cleanliness of the coil. 3. Application of a protective coating such as oil. A thin layer of oil or another protective substance is applied to the surface of the steel coil. This treatment prevents corrosion, improves lubricity, and safeguards the coil during storage and transportation. 4. Galvanizing, a process that involves coating the steel coil with a layer of zinc. This protective layer shields the coil from corrosion, creating a barrier between the steel and the surrounding environment. It ensures long-term durability and resistance to rust. 5. Tempering, a heat treatment process that includes heating the steel coil to a specific temperature and swiftly cooling it. This treatment enhances the toughness and strength of the coil, making it more resistant to impact and deformation. These are just a few instances of the various types of steel coil treatments commonly employed. Each treatment has its own unique purpose and advantages, and the choice of treatment will depend on the desired properties and applications of the coil.

- Q: I wanna strip down my bike and take off all the paint... im thinking of leaving it just the steal color... Do i need to put anythinng on the steel to coat it or can i just leave it like that... Will it rust or anything?

- It will rust but there is a product called POR that comes in clear, it will stop rust almost forever. If you don't want to go to that expense then rinse it down with acid. Ask at an automotive paint store for it.

- Q: How are steel coils processed?

- Steel coils are processed through a series of steps including pickling, cold rolling, annealing, and coating to achieve desired thickness, strength, and surface finish, making them ready for various applications in industries like automotive, construction, and manufacturing.

- Q: How do steel coils contribute to the packaging industry?

- Steel coils play a crucial role in the packaging industry by providing a durable and versatile material for packaging various products. The use of steel coils in packaging ensures the protection and preservation of goods during transportation and storage. One way steel coils contribute to the packaging industry is through their strength and durability. Steel is known for its high strength-to-weight ratio, making it an ideal material for packaging heavy and bulky items. Steel coils can withstand significant pressure and impact, ensuring that goods remain intact and undamaged throughout the supply chain. This strength also allows for the stacking of packages, optimizing storage space and reducing the risk of damage. Furthermore, steel coils are highly resistant to corrosion and moisture. This property is particularly important in the packaging industry as it helps protect goods from environmental factors that could potentially compromise their quality. Steel coils can be coated or treated to enhance their corrosion resistance, ensuring that packaged products remain in pristine condition. Steel coils are also versatile and can be easily customized to suit specific packaging requirements. They can be cut and shaped into various forms, such as sheets, straps, or bands, to secure and protect different types of products. Additionally, steel coils can be easily integrated with other packaging materials, such as cardboard or plastic, to provide added strength and stability. Another benefit of steel coils in the packaging industry is their recyclability. Steel is one of the most recycled materials globally, and steel coils can be easily recycled and reused. This sustainability aspect makes steel coils an environmentally friendly choice for packaging, contributing to the reduction of waste and the conservation of resources. In summary, steel coils play a vital role in the packaging industry by offering strength, durability, corrosion resistance, versatility, and recyclability. Their use ensures the safe transport and storage of goods, providing a reliable and sustainable packaging solution for a wide range of industries.

- Q: What are the common methods of transporting steel coils?

- Depending on factors such as coil size, weight, destination, and specific handling requirements, there are various common methods for transporting steel coils. These methods include: 1. Short-distance transportation: For short distances, steel coils are often transported using flatbed trucks. These trucks have a flat trailer bed that allows for easy loading and unloading of the coils. To prevent movement during transit, the coils are secured and strapped down. 2. Long-distance transportation: Rail transport is commonly preferred for longer distances due to its cost-effectiveness and efficiency. Specially designed railcars, known as coil cars or gondola cars, are used to securely hold the coils in place. This method is particularly advantageous for large quantities of steel coils. 3. International or long-distance transport: Shipping by sea is a common method for transporting steel coils internationally or over long distances. The coils are loaded into specialized shipping containers with internal cradles to prevent movement and damage during transit. These containers are then loaded onto cargo ships. 4. Waterway transportation: In regions with navigable waterways, barges can be used to transport steel coils. Similar to ocean freight, the coils are loaded into specially designed containers or barges with cradles to secure them during transport. Barge transport offers an economical and environmentally friendly option, especially for inland waterway transportation. 5. Combined transportation: In certain cases, a combination of different transportation modes, known as intermodal transport, may be used. For instance, steel coils can be initially transported by truck and then loaded onto railcars for long-distance transport. This approach allows for the optimization of cost and efficiency by utilizing the advantages of different transportation modes. It's important to note that the specific method of transporting steel coils can vary based on various factors, including coil size, weight, destination, and any specific handling requirements.

Send your message to us

Hot-dip Zinc Coating Steel Sheets in Coils

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords