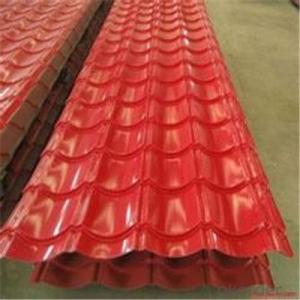

Hot-dip Zinc Coating Steel Building Roof Sheets Prime Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

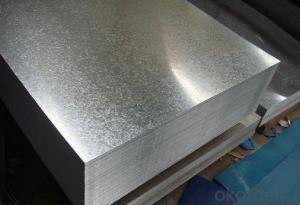

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

Processability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: Can steel sheets be used for solar panel structures?

- Yes, steel sheets can be used for solar panel structures. Steel is a popular choice for constructing solar panel structures due to its strength, durability, and versatility. Steel sheets can be easily fabricated and shaped to meet specific design requirements, making them suitable for various types of solar panel installations. Additionally, steel has excellent load-bearing capabilities, which is crucial for supporting the weight of solar panels. It is also resistant to corrosion and can withstand harsh weather conditions, making it a reliable material for long-term use in outdoor settings. Overall, the use of steel sheets for solar panel structures is a practical and cost-effective solution.

- Q: What are the limitations of using steel sheets?

- There are several limitations associated with using steel sheets in various applications. Firstly, steel sheets are relatively heavy compared to other materials, which can pose challenges in terms of transportation and installation. This weight can also limit their use in applications where weight reduction is critical, such as aerospace or automotive industries. Secondly, steel sheets are susceptible to corrosion, especially when exposed to moisture and chemicals. If not properly protected, this can lead to rusting and a decrease in structural integrity over time. Therefore, additional coatings or treatments are often required to prevent corrosion, adding to the overall cost and maintenance requirements of steel sheet usage. Another limitation is that steel sheets have limited flexibility and cannot be easily molded or shaped into complex forms. This restricts their use in applications where intricate designs or curved surfaces are required, such as in the construction of curved roofs or architectural structures. Furthermore, steel sheets have poor thermal insulation properties, meaning they conduct heat and cold more readily than other materials. This can result in temperature fluctuations and energy loss in buildings, requiring additional insulation measures to maintain thermal comfort and energy efficiency. Lastly, steel sheets are a finite resource and their production can have a significant environmental impact. The extraction of raw materials, energy consumption, and carbon emissions associated with steel production make it less sustainable compared to alternative materials. In summary, while steel sheets are widely used for their strength and durability, their limitations include their weight, susceptibility to corrosion, limited flexibility, poor thermal insulation properties, and environmental impact. These limitations should be considered when selecting materials for specific applications.

- Q: Can steel sheets be used in the food processing industry?

- Yes, steel sheets can be used in the food processing industry. Steel is a popular choice for food processing equipment and materials due to its strength, durability, and corrosion resistance. It is commonly used in the construction of food storage tanks, conveyor belts, cutting surfaces, and other machinery. Additionally, steel sheets can be easily cleaned and sanitized, making them suitable for maintaining high hygiene standards in food processing facilities.

- Q: What is the price range of steel sheets?

- The cost of steel sheets can differ based on various factors, including the steel's type and grade, the sheet's thickness and size, and the prevailing market conditions. Typically, steel sheets can be priced between $0.60 and $1.50 per pound. Nevertheless, it is crucial to note that these figures are only approximate and subject to frequent modifications due to fluctuations in the steel market and other economic elements. To obtain the most precise and current pricing details for steel sheets, it is recommended to consult local suppliers or utilize online platforms.

- Q: What are the different storage methods for steel sheets?

- There are several different storage methods for steel sheets, depending on the specific requirements and space availability. Here are some commonly used storage methods: 1. Flat storage: This is the most basic method where steel sheets are stored horizontally on a flat surface, such as the floor or metal racks. It is suitable for small quantities or when the sheets are not too heavy. 2. Vertical storage: Steel sheets can be stored vertically by placing them against a wall or by using specially designed vertical racks. This method saves floor space and allows for easy access and identification of different sheet sizes. 3. Cantilever racks: These racks have horizontal arms that extend outward from a vertical column, providing support for steel sheets placed on them. Cantilever racks are ideal for storing long and heavy steel sheets, as they allow for easy loading and unloading using forklifts or cranes. 4. Roll-out racks: These racks have rollers or ball bearings that allow steel sheets to be easily rolled in and out, similar to a drawer. Roll-out racks are useful when frequent access to different sheets is required, as they provide good visibility and easy retrieval. 5. A-frame racks: A-frame racks have angled arms that support steel sheets in a slanted position, resembling the letter "A." This method is suitable for storing large quantities of steel sheets and provides easy access while keeping them organized. 6. Automated storage and retrieval systems (AS/RS): These systems use computer-controlled mechanisms to automatically store and retrieve steel sheets. AS/RS can be designed as vertical lift modules or robotic systems, maximizing storage capacity and efficiency. It is important to consider factors such as sheet size, weight, accessibility, and safety when choosing the appropriate storage method for steel sheets. Adequate measures should also be taken to protect the sheets from moisture, dust, and other environmental factors that could potentially affect their quality.

- Q: What is the process of laminating steel sheets?

- The process of laminating steel sheets involves several steps to create a composite material that is stronger and more durable than traditional steel. First, the steel sheets are cleaned and prepped to remove any impurities or contaminants. This is important to ensure a strong bond between the layers and prevent any defects in the final product. Next, a layer of adhesive is applied to one or both sides of the steel sheets. The adhesive can be a thermosetting resin or a thermoplastic material, depending on the desired properties of the laminated steel. After the adhesive is applied, the steel sheets are stacked together, with the adhesive layer(s) in between. The sheets are then subjected to high temperature and pressure to initiate the bonding process. This can be done using a hydraulic press or a hot rolling mill. The combination of heat and pressure causes the adhesive to melt and flow, creating a strong chemical bond between the steel sheets. The high pressure ensures that the adhesive is evenly distributed and fills any gaps or irregularities between the sheets. Once the bonding process is complete, the laminated steel sheets are cooled and trimmed to the desired size and shape. They can then be further processed, such as by cutting, bending, or welding, to meet specific application requirements. Overall, the process of laminating steel sheets involves cleaning and prepping the sheets, applying adhesive, stacking the sheets, subjecting them to high temperature and pressure, cooling, and finalizing the shape. This process results in a composite material with improved strength, corrosion resistance, and other desirable properties compared to traditional steel.

- Q: Can the steel sheets be easily painted or coated?

- Indeed, it is possible to effortlessly paint or coat steel sheets. The sleek texture of these sheets enables exceptional paint or coating adherence. Before proceeding with the painting or coating process, it becomes crucial to diligently cleanse the surface to eliminate any potential dirt, grease, or rust that may hinder proper adhesion. Additionally, the utilization of a primer or base coat can considerably augment the resilience and longevity of the applied paint or coating. In summary, steel sheets furnish a fitting and conveniently paintable surface for an array of purposes.

- Q: What is the density of steel sheets?

- The density of steel sheets typically ranges from 7.8 to 8.1 grams per cubic centimeter.

- Q: How do steel sheets compare to fiberglass sheets?

- Different applications require distinct characteristics from steel sheets and fiberglass sheets. Steel sheets are renowned for their strength and durability, enabling them to withstand heavy loads and resist impact and abrasion. Additionally, steel sheets provide exceptional fire resistance, making them an ideal choice for applications prioritizing fire safety. Furthermore, steel sheets require relatively low maintenance and can endure harsh weather conditions, making them a popular option for outdoor structures like roofing and siding. On the contrary, fiberglass sheets possess the advantage of being lightweight and highly resistant to corrosion. Typically composed of woven glass fibers embedded in a resin matrix, fiberglass sheets offer a high strength-to-weight ratio. Moreover, they are non-conductive, making them suitable for applications requiring electrical insulation. Notably, fiberglass sheets are also transparent to electromagnetic waves, particularly radio waves, making them widely used in industries such as telecommunications. While steel sheets excel in providing superior strength for heavy-duty applications, fiberglass sheets shine in areas where considerations of weight, corrosion resistance, and electrical insulation are crucial. Ultimately, the choice between steel sheets and fiberglass sheets hinges on the specific requirements of the application and the desired characteristics necessary to fulfill those requirements.

- Q: Can steel sheets be used for electrical motors?

- Yes, steel sheets can be used for electrical motors. Steel is commonly used in the construction of motor cores as it provides high magnetic permeability, low hysteresis, and low eddy current losses, which are essential for efficient operation of electrical motors.

Send your message to us

Hot-dip Zinc Coating Steel Building Roof Sheets Prime Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords