Hot-Dip Galvanized Steel Sheet in Competitive Price and High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

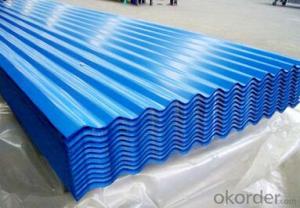

Hot-dip Zinc Coating Steel Building Roof Walls

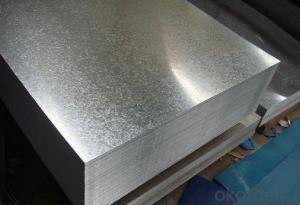

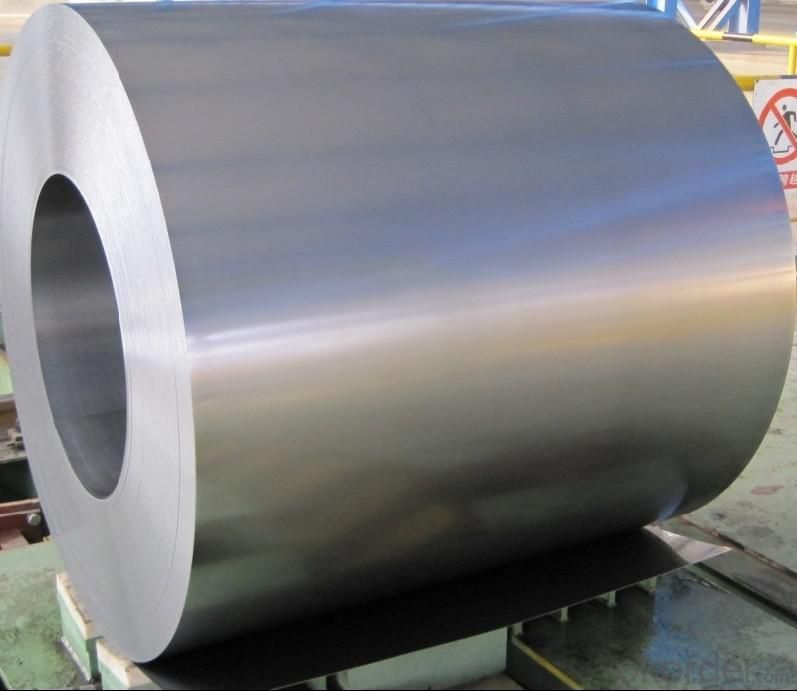

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

| Processability | Yield strength | Elongation % | Elongation % | 180°cold-bending |

| Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

| Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

| Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

| Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

| EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: What are the common applications of galvannealed steel sheets?

- Galvannealed steel sheets are commonly used in various industries for applications such as automotive body panels, appliances, HVAC systems, electrical enclosures, and construction components. The galvannealed coating provides enhanced corrosion resistance and improved paint adhesion, making it ideal for these applications where durability and aesthetic appeal are important.

- Q: Can steel sheets be bent or shaped?

- Yes, steel sheets can be bent or shaped using various techniques such as rolling, pressing, or folding.

- Q: Can steel sheets be formed into curved shapes?

- Yes, steel sheets can be formed into curved shapes through various processes such as bending, rolling, or forming.

- Q: Can the steel sheets be easily drilled or machined?

- Yes, steel sheets can be easily drilled or machined with the right tools and equipment.

- Q: Are the steel sheets heat-resistant?

- Yes, steel sheets are heat-resistant.

- Q: Can steel sheets be used for walkways and platforms?

- Yes, steel sheets can be used for walkways and platforms. Steel sheets are often used in the construction of walkways and platforms due to their strength, durability, and resistance to various environmental factors. They provide a stable and secure surface for walking and can be customized to meet specific design requirements.

- Q: Are steel sheets resistant to impact or damage?

- Steel sheets are known for their exceptional strength and durability, which makes them highly resistant to impact and damage. Due to their high tensile strength, steel sheets can withstand heavy loads and resist deformation or breakage when subjected to external forces. They are often used in applications where impact resistance is critical, such as in construction, automotive manufacturing, and industrial settings. Additionally, steel sheets can withstand extreme temperatures, corrosion, and environmental factors, which further contributes to their overall resistance to damage. However, it is important to note that the specific resistance to impact or damage may vary depending on the thickness, quality, and composition of the steel sheet.

- Q: How do steel sheets perform in marine environments?

- Steel sheets are well-suited for marine environments because they possess high strength and corrosion resistance properties. The presence of saltwater and high levels of moisture in these environments can cause significant damage to many materials; however, steel sheets are specifically designed to endure such conditions. Corrosion resistance is a key factor contributing to the performance of steel sheets in marine environments. Typically, steel sheets are coated with zinc or other protective coatings like epoxy or galvanized coatings, which act as a barrier against corrosion. These coatings prevent direct contact between the steel and saltwater, reducing the risk of rust and deterioration. Moreover, the high strength of steel sheets makes them highly durable in marine environments. They can withstand harsh conditions such as waves, strong winds, and impact from debris. This strength ensures that steel sheets maintain their structural integrity and offer long-term performance. Furthermore, steel sheets are known for their fire resistance, which is crucial in marine environments where safety is a top concern. Steel has a high melting point and does not contribute to the spread of fire, making it a reliable choice for marine applications. Nevertheless, it is important to note that even with their excellent performance, steel sheets may still require regular maintenance and inspection in marine environments. This includes monitoring for signs of corrosion, repairing or replacing damaged coatings, and addressing any potential issues promptly to ensure continued performance. In conclusion, steel sheets are a reliable option for marine environments due to their corrosion resistance, high strength, and fire resistance. They can withstand the challenging conditions of saltwater, moisture, and impact, making them an ideal material for various marine applications.

- Q: How long do steel sheets last?

- Steel sheets can last for many years, often surpassing the lifespan of other materials. The longevity of steel sheets depends on various factors such as the quality of the steel, the conditions it is exposed to, and how well it is maintained. In general, high-quality steel sheets that are properly installed and maintained can last for several decades or even longer. However, if steel sheets are exposed to harsh environments, such as extreme temperatures, humidity, or corrosive substances, their lifespan may be reduced. Regular inspections, cleaning, and maintenance can help extend the lifespan of steel sheets and ensure their durability over time.

- Q: What is the difference between a black and pickled steel sheet?

- A black steel sheet refers to a plain carbon steel sheet that has not undergone any additional surface treatment. It has a characteristic dark appearance due to the presence of an iron oxide scale on its surface. On the other hand, a pickled steel sheet has undergone a surface treatment process called pickling, which involves removing the oxide scale using an acid solution. This treatment results in a clean and smooth surface, making it more suitable for further processing or application.

Send your message to us

Hot-Dip Galvanized Steel Sheet in Competitive Price and High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords