Hot DIP Galvanized Steel Coils Regular 1000mm 1250mm Z60-Z120

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot DIP Galvanized Steel Coils Regular 1000mm 1250mm Z60-Z120 Dx51d+Z, DC01

Product Description

Description:

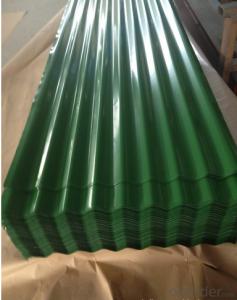

EN 10147 Structure hot dip galvanized steel coil S250GD+Z, S350GD+Z (SGC340, SS275, SS340)/Custom Deep drawing hot dip galvanized steel coil DX52D+Z, DX53D+Z, S

Galvanized steel is taken cold rolled steel as the base metal, after continuous hot dip galvanizing process, the product produced is an excellent resistance to atmospheric corrosion coating steel coil, as the steel gets coated in layers of zinc and rust won't attach this protective metal; Cold rolled plate by hot-dip galvanizing may extend the service life of 15-20 years.

For countless outdoor, marine, or industrial applications, galvanized steel is an essential fabrication component. Hot dip galvanized steel is used in applications where steel may be exposed to weather, but where stainless steel is too expensive.

Application:

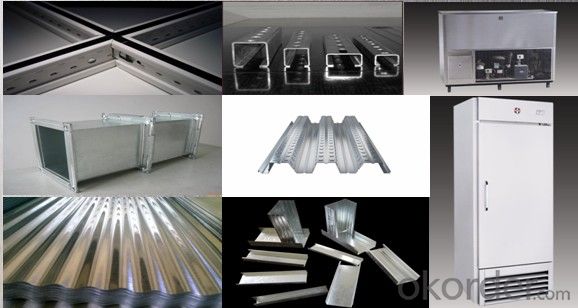

Construction

Manufacture anticorrosion, industrial and civil architecture roof boarding, roof grille

Light industries

Home appliance's case, civil chimney, kitchen utensils

Auto industry

Corrosion resistant parts of cars

Agriculture

Food storage, meat and aquatic products' freezing and processing equipment

Commerce

Equipments to store and transport materials, and packing implements

andard | EN 10142 | DX51D+Z, DX52D+Z, DX53D+Z |

JIS G3321 | SGCC, SGCD, SGCDD, SGC400 | |

ASTM A792M | CS type C, CS type B, DS, SS250 | |

Base Metal | Cold rolled steel coils SPCC, SPCD, SPCE, DC01, DC03, DC04, CS, DS, DDS, Q195, Q250, Q350 | |

Thickness | 0.14mm-3.0mm | |

Width | 600mm-1600mm | |

Coil ID | 508mm, 610mm | |

Zinc coating | 60g/m2-450g/m2 | |

Surface treating | chromium free passivation, chromium passivation, fingerprint resistant, oiled | |

Spangle types | Minimal spangle, zero spangle, regular and big spangle | |

FAQ

1.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

2. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

3.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

4. Is the sample available?

Yes, samples can be sent for test if you need.

- Q: How are steel coils priced in the market?

- Steel coils are typically priced in the market based on various factors such as the current supply and demand dynamics, global steel prices, production costs, and market competition. Additionally, specific attributes of the steel coils, such as size, thickness, grade, and coating, can also influence the pricing. Overall, it is a complex process that involves analyzing multiple factors to determine the appropriate price for steel coils in the market.

- Q: How are steel coils used in the production of steel doors?

- Steel coils are used in the production of steel doors by being processed and shaped into sheets, which are then cut and formed to create the desired door components. These coils provide the raw material for manufacturing steel doors, ensuring their strength, durability, and structural integrity.

- Q: and which one is better?i'm looking into buying some aftermarket headers, but companies make them in both chrome and stainless steel

- For headers go with stainless steel. Chrome holds heat in, and after a while it will discolor due to the high heat of the heads.

- Q: What are the different types of steel coil surface finishes for aesthetics?

- For aesthetic purposes, steel coil surface finishes come in various types. These finishes are applied to the steel coil surface to improve its appearance and achieve the desired aesthetic appeal. Some popular steel coil surface finishes are: 1. Polished Finish: Achieved by using abrasive materials, this finish creates a smooth and reflective surface on the steel coil. Different levels of polishing can further enhance its high-gloss appearance. 2. Satin Finish: Also known as brushed finish, this type of surface finish involves using fine abrasives to achieve a soft and matte appearance on the steel coil. It provides a subtle sheen and a textured effect. 3. Etched Finish: This finish involves a chemical process to create patterns or designs on the steel coil surface. It is commonly used for architectural applications, as it allows for intricate and decorative designs. 4. Embossed Finish: By pressing or stamping a pattern onto the steel coil surface, this finish creates a raised design that adds texture and visual interest. 5. Powder Coated Finish: A dry powder is applied to the steel coil and then heated, resulting in a protective and decorative coating. Available in a wide range of colors, it provides a durable and vibrant finish. 6. Painted Finish: This finish involves applying a layer of paint to the steel coil surface. It allows for customization in terms of color and provides protection against corrosion and environmental factors. These examples highlight the different steel coil surface finishes available for aesthetic purposes. Each finish offers a unique appearance and can be selected based on personal preferences and project requirements.

- Q: How are steel coils inspected for edge quality using visual inspection?

- Steel coils are inspected for edge quality using visual inspection methods to ensure that they meet the required standards and specifications. Visual inspection involves carefully examining the edges of the steel coils to identify any defects or imperfections that may have occurred during the manufacturing process or handling. During the inspection, trained inspectors visually examine the edges of the steel coils for various parameters such as burrs, cracks, uneven edges, roughness, or any other irregularities that could affect the quality and performance of the steel. They use specialized tools such as magnifying glasses, microscopes, or cameras to closely observe and analyze the edges. Inspectors carefully inspect each coil, looking for any signs of defects that could potentially impact the functionality or integrity of the steel. They pay close attention to details, ensuring that the edges are smooth, free from any sharp edges or protrusions, and have consistent dimensions throughout the coil. In addition to visual inspection, inspectors may also use specific testing methods such as dye penetrant testing or ultrasonic testing to further assess the quality of the steel coil edges. These additional tests help to detect any hidden defects that may not be visible to the naked eye. Overall, visual inspection is an important part of the quality control process for steel coils, as it allows for the identification and elimination of any edge defects that could compromise the performance and durability of the steel. By ensuring that the edges meet the required standards, visual inspection helps to maintain the quality and reliability of the steel coils.

- Q: please i need your help in answering this question manufacturing process of steel containers and 20 references

- There are many types of steel containers and many different mnfg processes. There are also thousands of different steel alloys. Steel is used for canned food, compressed air cyclinders, hydraulic pressure vessels, electrical boxes, and many other containers. Steel containers are made out of sheet metal by soldering, brazing, spot welding, seam welding, riveting, bolting, screwing, etc. Heavier wall containers are fabricated of plate steel. Some steel containers are made by deforming the steel by extruding, forging, spin forming, drawing, ironing, etc. Some steel containers are made by machining. You should be able to find plenty of references if you search for these terms. good luck

- Q: I'm pretty sure that this topic has been beaten to death by now. But, I still can't get a definite answer. With stainless steel, you get better corrosion resistance, and you will hold and edge longer. With carbon steel, you will hold a sharper edge, and you could forge a knife blade longer than 2 ft without breakage. I'm personally a fan of stainless steel ( the 440 grade stuff ), just because it seems to hold up to use and abuse better in the long run. HOWEVER, I have NEVER had a factory made knife break on me. I don't think that they would try to sell you a knife that didn't do what it was meant to do, at least to a reasonable degree. (I work for a living, and can't afford a custom $600 knife.) What do you think? Is this a pointless topic? Will there ever be a winner?

- You didn't say WHICH type of stainless steel, which will make all the difference. There are $2 stainless steel knives and $200 stainless steel knives. The best stainless knife steels will rival the best high carbon steels when it comes to edge-holding properties. These days MOST of the best knives on the market are made from premium stainless steels because of the lower maintenance, but a high carbon steel knife has classic appeal and great edge-holding properties.

- Q: What are the different types of steel coatings for coil protection?

- There are several types of steel coatings for coil protection, including galvanized coatings, zinc coatings, aluminum coatings, and polymer coatings.

- Q: Hey guys do you know anything about Steel Arch Building and how this structure really looks like?

- Just google steel arch building, you will get plenty of selection , pictures, prices and designs

- Q: How are steel coils used in the production of industrial tanks?

- Steel coils are used in the production of industrial tanks as they are rolled and formed into the desired shape to create the tank's structure. The coils provide the necessary strength and durability required to withstand the pressure and weight of the tank's contents.

Send your message to us

Hot DIP Galvanized Steel Coils Regular 1000mm 1250mm Z60-Z120

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords