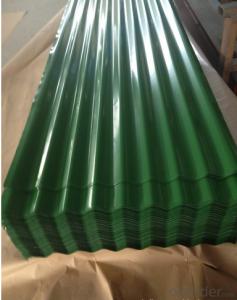

Hot DIP Galvanized Steel Coils Regular 1000mm 1219mm 1250mm Z60-Z120

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info.

Type:Steel Coil

Technique:Cold Rolled

Standard:ASTM, AISI, GB, JIS, DIN, BS

Surface Treatment:Galvanized

Special Use:Wear Resistant Steel

Application:Ship Plate, Boiler Plate, Container Plate, Flange Plate

Steel Thickness:0.12-3mm

Width:300 to 1500

Export Markets:Global

Additional Info.

Packing:Standard Package

Standard:PRIME

Production Capacity:10000 Tons Per Month

Product Description

Description:

EN 10147 Structure hot dip galvanized steel coil S250GD+Z, S350GD+Z (SGC340, SS275, SS340)/Custom Deep drawing hot dip galvanized steel coil DX52D+Z, DX53D+Z, S

Galvanized steel is taken cold rolled steel as the base metal, after continuous hot dip galvanizing process, the product produced is an excellent resistance to atmospheric corrosion coating steel coil, as the steel gets coated in layers of zinc and rust won't attach this protective metal

For countless outdoor, marine, or industrial applications, galvanized steel is an essential fabrication component. Hot dip galvanized steel is used in applications where steel may be exposed to weather, but where stainless steel is too expensive.

Application:

Construction

Manufacture anticorrosion, industrial and civil architecture roof boarding, roof grille

Light industries

Home appliance's case, civil chimney, kitchen utensils

Auto industry

Corrosion resistant parts of cars

Agriculture

Food storage, meat and aquatic products' freezing and processing equipment

Commerce

Equipments to store and transport materials, and packing implements

| andard | EN 10142 EN 10147 | DX51D+Z, DX52D+Z, DX53D+Z SS250GD+Z, SS350GD+Z |

| JIS G3321 | SGCC, SGCD, SGCDD, SGC400 | |

| ASTM A792M | CS type C, CS type B, DS, SS250 | |

| Base Metal | Cold rolled steel coils SPCC, SPCD, SPCE, DC01, DC03, DC04, CS, DS, DDS, Q195, Q250, Q350 | |

| Thickness | 0.14mm-3.0mm | |

| Width | 600mm-1600mm | |

| Coil ID | 508mm, 610mm | |

| Zinc coating | 60g/m2-450g/m2 | |

| Surface treating | chromium free passivation, chromium passivation, fingerprint resistant, oiled | |

| Spangle types | Minimal spangle, zero spangle, regular and big spangle | |

- Q: I'm getting new strings on my dad's old acoustic guitar so I can learn how to play it and I'm wondering if I should get nylon or steel strings. Are there any major differences between the two aside from the nylon strings being easier on your fingers? Like do the Nylon strings sound different?

- Well there definitely is a difference in sound. It kind of depends on what type of music you're getting into. If you what to play more pop/rock songs I'd go with steel. But for classical guitar or folk music, go with the nylon.

- Q: What are the safety precautions while handling steel coils?

- Some safety precautions while handling steel coils include wearing protective gloves and clothing to prevent cuts and scrapes, using proper lifting techniques to avoid back injuries, ensuring a clear and organized work area to prevent tripping hazards, and using appropriate equipment, such as forklifts or cranes, to safely move and stack the coils. It is also important to follow proper storage procedures to prevent the coils from falling or shifting and causing accidents.

- Q: i have a sword and some knives that have this grade steel. so is it a high grade or low grade? and how can i tell the differance between a high grade and a low grade?

- I own a claymore made of 440 stainless steel, I cut a small tree in half. I was surprised, I mean I had always heard it broke very easily, but tell that to the tree. In other words it is a strong metal, but I don't sugest you tempt fate and try to break it because you will. As far as high grade the higher the grade the better the blade looks. If your looking for something to swing around, listen up Damascus is a good steel and Superalloys are probably the best. Take it from me, i'm an expert in using a sword and you'll only get hurt. Most of the time when you swing a sword you wound yourself and don't know it. When you swing the hilt of the sword also presents a problem, it can wound you too. Infact if you can't live with being cut up all the time don't pick up a sword. I cut my hands all the time and i'm a professional so you would probably kill yourself trying. Of course I do use heavy swords, but you can still hurt yourself with a light sword. So don't attempt anything stupid for your sake.

- Q: How are steel coils used in the production of building systems?

- Steel coils are used in the production of building systems as they serve as the primary raw material for manufacturing various structural components such as beams, columns, and trusses. These coils are processed through different techniques like cutting, bending, and welding to create the desired shape and size of the building elements. The strength and durability of steel make it an ideal material for constructing robust and long-lasting building systems.

- Q: What is the difference between galvanized and galvalume steel coils?

- Galvanized and galvalume steel coils are both types of steel coils that have undergone a coating process to enhance their durability and resistance to corrosion. However, there are distinct differences between the two. Galvanized steel coils are coated with a layer of zinc. This coating provides excellent corrosion resistance and protects the underlying steel from rust and other forms of deterioration. The zinc coating also acts as a barrier against moisture and prevents the steel from coming into direct contact with the elements. Galvanized steel coils are commonly used in applications where corrosion resistance is crucial, such as in construction, automotive manufacturing, and agricultural equipment. On the other hand, galvalume steel coils are coated with a combination of zinc and aluminum. This unique coating composition provides enhanced corrosion resistance compared to galvanized steel coils. The aluminum in the coating acts as a sacrificial anode, offering additional protection to the steel by sacrificially corroding instead. This sacrificial protection mechanism helps the underlying steel to remain intact and prevents the spread of corrosion even if the coating is damaged. Galvalume steel coils are often used in environments where extreme weather conditions and high humidity are prevalent, making them suitable for roofing, siding, and other outdoor applications. In summary, the main difference between galvanized and galvalume steel coils lies in the composition of their coatings. Galvanized steel has a zinc coating, while galvalume steel has a combination of zinc and aluminum. Galvalume steel offers superior corrosion resistance due to the sacrificial protection provided by the aluminum in the coating. The choice between the two depends on the specific application and the level of corrosion resistance required.

- Q: How are steel coils used in the production of steel hooks?

- Steel coils are used in the production of steel hooks as they provide the raw material needed for shaping, forming, and manufacturing the hooks. The coils are unwound, processed, and then transformed into the desired shape and size to create the steel hooks.

- Q: What would be a better knife one with damascus steel or one without? Why is damascus steel so special other than the look? And why do some people say high carbon steel is better than regular? mainly though I want to know about the damascus. Thanks, max points to best answer.

- This Site Might Help You. RE: Is a knife with damascus steel better than one with regular steel? or what about high carbon? What would be a better knife one with damascus steel or one without? Why is damascus steel so special other than the look? And why do some people say high carbon steel is better than regular? mainly though I want to know about the damascus. Thanks, max points to best answer.

- Q: What are the different types of steel coil slitting blades?

- Different types of steel coil slitting blades are available to suit specific applications and materials. The following are some commonly used types: 1. Circular slitting blades: These blades, which are circular in shape, are widely used for slitting steel coils. They have a sharp edge that cuts through the coil as it rotates. The choice of material for circular slitting blades, such as high-speed steel or tungsten carbide, depends on the desired cutting performance and durability. 2. Arbors: Arbors are cylindrical blades used in conjunction with circular slitting blades. They hold the circular blade in place, allowing for precise and consistent slitting of the coil. 3. Shear slitting blades: These blades are used for cutting thicker and harder materials like stainless steel or aluminum. They have a straight edge and work by shearing the material apart, rather than cutting through it like circular blades. Shear slitting blades are typically made from high-quality tool steel to withstand the high forces involved in cutting thicker materials. 4. Crush cut slitting blades: Crush cut blades are suitable for slitting softer materials like paper or plastic. They have a blunt edge that crushes and tears the material instead of cutting it cleanly. Crush cut blades are often made from materials like carbon steel or hardened stainless steel. 5. Razor slitting blades: Razor slitting blades are ideal for slitting delicate materials that require a clean and precise cut, such as thin films or foils. They have an extremely sharp edge that slices through the material without causing any damage or distortion. Razor slitting blades are typically made from high-quality stainless steel or tungsten carbide. Choosing the right type of steel coil slitting blade is crucial and depends on factors such as the specific application, material, and desired cutting performance. The blade selection significantly affects the quality and efficiency of the slitting process.

- Q: How are steel coils used in the production of shelving units?

- Steel coils are used in the production of shelving units by being cut and formed into various components, such as brackets and supports. These components are then assembled and welded together to create the frame and structure of the shelving unit. The steel coils provide strength and durability to the shelving units, ensuring they can withstand heavy loads and provide long-lasting storage solutions.

- Q: What is the process of uncoiling a steel coil?

- The process of uncoiling a steel coil involves using specialized equipment, such as a decoiler or uncoiler machine, that is designed to carefully unwind the tightly wound coil. The coil is typically mounted onto the machine's mandrel, which holds it securely in place. As the machine rotates, the coil starts to unwind, with the outer layers gradually releasing and straightening out. This process continues until the entire coil is uncoiled, resulting in a flat and straight steel sheet or strip ready for further processing or use in various applications.

Send your message to us

Hot DIP Galvanized Steel Coils Regular 1000mm 1219mm 1250mm Z60-Z120

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords