GI/Hot DIP Galvanized Steel Coils Regular 1000mm 1219mm 1250mm Z60-Z120 Dx51d+Z, DC01

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Description:

EN 10147 Structure hot dip galvanized steel coil S250GD+Z, S350GD+Z (SGC340, SS275, SS340)/Custom Deep drawing hot dip galvanized steel coil DX52D+Z, DX53D+Z, S

Galvanized steel is taken cold rolled steel as the base metal, after continuous hot dip galvanizing process, the product produced is an excellent resistance to atmospheric corrosion coating steel coil, as the steel gets coated in layers of zinc and rust won't attach this protective metal; Cold rolled plate by hot-dip galvanizing may extend the service life of 15-20 years.

For countless outdoor, marine, or industrial applications, galvanized steel is an essential fabrication component. Hot dip galvanized steel is used in applications where steel may be exposed to weather, but where stainless steel is too expensive.

Application:

Construction

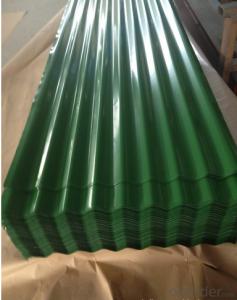

Manufacture anticorrosion, industrial and civil architecture roof boarding, roof grille

Light industries

Home appliance's case, civil chimney, kitchen utensils

Auto industry

Corrosion resistant parts of cars

Agriculture

Food storage, meat and aquatic products' freezing and processing equipment

Commerce

Equipments to store and transport materials, and packing implements

andard | EN 10142 | DX51D+Z, DX52D+Z, DX53D+Z |

JIS G3321 | SGCC, SGCD, SGCDD, SGC400 | |

ASTM A792M | CS type C, CS type B, DS, SS250 | |

Base Metal | Cold rolled steel coils SPCC, SPCD, SPCE, DC01, DC03, DC04, CS, DS, DDS, Q195, Q250, Q350 | |

Thickness | 0.14mm-3.0mm | |

Width | 600mm-1600mm | |

Coil ID | 508mm, 610mm | |

Zinc coating | 60g/m2-450g/m2 | |

Surface treating | chromium free passivation, chromium passivation, fingerprint resistant, oiled | |

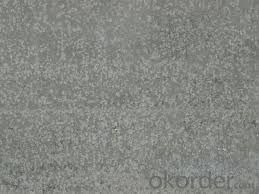

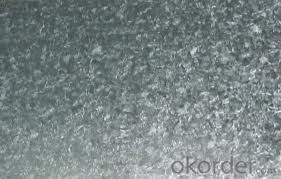

Spangle types | Minimal spangle, zero spangle, regular and big spangle | |

- Q: Are steel coils resistant to rust and corrosion?

- Steel coils exhibit resistance to rust and corrosion. Typically, these coils are crafted from either carbon steel or stainless steel, both of which possess exceptional properties for combating corrosion. Carbon steel coils are frequently coated with a protective layer, such as zinc or a polymer coating, to augment their resistance to rust and corrosion. Conversely, stainless steel coils possess inherent corrosion-resistant qualities due to the presence of chromium. This element creates a protective oxide layer on the steel's surface, effectively preventing rust and corrosion. Nonetheless, it is crucial to acknowledge that the extent of resistance may also hinge on the specific grade and quality of the steel employed in the coils, as well as the environmental conditions to which they are exposed.

- Q: How are steel coils coated for added protection?

- To enhance their durability and resistance to corrosion, steel coils undergo a process known as coil coating, wherein a protective layer is applied onto their surfaces. There are several methods employed to coat steel coils, but the most commonly used one is the continuous coil coating process. Under this process, the steel coil is unwound and extensively cleansed to eliminate any contaminants or impurities on its surface. This step ensures proper adhesion of the coating material. Once the steel coil is cleansed, it undergoes a pre-treatment to enhance its surface properties. Typically, this involves the application of a chemical solution or a conversion coating onto the coil's surface. The aim of this step is to create a surface that is receptive to the coating material and improves its adhesion. Following the pre-treatment, the steel coil is coated with a protective layer, which can be in the form of liquid paint, powder coating, or a combination of both. The coating material is applied evenly onto the coil's surface using techniques like roll coating, spray coating, or electrostatic coating. Once the coating is applied, the steel coil is cured or dried using heat or, in some cases, ultraviolet light. This curing process ensures a strong bond between the coating material and the steel surface, resulting in the desired protective properties. The coated steel coil then undergoes inspection to ensure quality control measures like thickness, adhesion, and appearance are met. If the specifications are satisfied, further processing may take place, involving cutting, slitting, or forming the coil into the desired shape or size. In conclusion, the process of coating steel coils for added protection involves thorough cleansing, pre-treatment, application of a protective coating, curing, and quality control. This ensures that the steel coils exhibit excellent resistance to corrosion, abrasion, and other environmental factors, making them suitable for a wide range of applications across various industries.

- Q: Hello. No freakin' website has no dam info on what products have carbon steel in them. I know it's in cooking equipment and tools, but what tools?i.e It's in a wrench or strainerSo what products have carbon steel in them?

- there are too many products that have carbon steel in them. just ask yourself whether it rusts, if it does then it has carbon steel. If not then it probably isn't.

- Q: I bought a stainless steel water bottle today. I really like it, but there is no drinking spout, it just has a lid that screws on and off, and an open hole to fill it and drink out of. Is this normal for these bottles? Or do they usually come with a spout to drink from? I don't want to look like an idiot at the gym drinking from this cool bottle with no spout if there's supposed to be one! haha.

- If okorder /...

- Q: Has anyone painted their appliences with stainless steel paint? I found on the internet what is called Thomas Liquid stainless steel paint. If you have used it for your kitchen appliences or cabinets, how were the results? How hard was it to apply? Would you recommend it?

- If okorder /

- Q: What are the common methods of recoiling steel coils?

- The common methods of recoiling steel coils include slitting, rewinding, oscillating, and recoiling using a mandrel or a recoiler machine. Slitting involves cutting the wide coil into smaller widths, while rewinding involves rewinding the coil into a tighter, more compact roll. Oscillating is a method where the coil is wound back and forth to create a narrow, oscillating coil. Finally, recoiling using a mandrel or a recoiler machine involves winding the coil onto a mandrel or a spool to create a new coil of desired size and shape.

- Q: Why is it usually scorned by the shooting community to use steel cased ammo (like Wolf)? Always hear corrosive and steel is bad for the extractor/firing pin. Hulp a simpleton out!

- if you were going to shoot thousands upon thousands of steel cases in your rifle, it would cause more wear than brass cases do. but for the casual shooter, it won't be a significant factor. Corrosive ammo is another story (but not all steel cased ammo is corrosive, and any made after 1975 is not corrosive). shooting corrosive ammo in a bolt gun is simple to care for. When finished shooting, simply clean out the barrel, chamber and bolt face etc with hot soapy water, or military bore cleaner. This nuetralizes the corrosive chemicals. then dry it well, and then do your normal clean and lube with break free CLP or whatever other lube you prefer. But for a semi auto, gas operated firearm, the cleaning process takes hours, with having to tear it down and clean every part including gas tube etc. As for the ectractor, same answer as above, since an extractor slides in front of the rim as the cartridge is fed, it really does not add much more wear if it is steel. The firing pin does not contact the steel case, only the primer, so no additional wear there. The biggest problem with wolf ammo is encountered when you fire a lot of rounds quickly, building up a lot of heat, which can cause the lacquer sealent on the case to turn gummy and this in turn will cause problems for the firearm. Answer? first, use wolf ammo for casual shooting and clean the firearm extensively afterwords. Save your better ammo for real life situations. I understand that some of the newer wolf ammo does not use the same lacquer sealant. I believe it is called silver bear, but don't quote me becasue I can't swear that that is it. shoot safe

- Q: What are the key properties of steel coils?

- The key properties of steel coils include their strength, durability, and flexibility. Steel coils are known for their high tensile strength, making them suitable for various applications that require load-bearing capacity. They also exhibit excellent durability, resisting wear, corrosion, and damage over time. Additionally, steel coils are highly flexible, allowing for easy shaping and forming into different structures or products.

- Q: What are the different types of steel coil edge treatments?

- There are several different types of steel coil edge treatments, including mill edge, slit edge, deburred edge, and rounded edge. Mill edge refers to the original edge of the steel coil as it comes from the mill, which is typically sharp and uneven. Slit edge is a straight and smooth edge created by slitting the coil. Deburred edge is a process of removing any burrs or sharp edges from the coil edge to provide a smoother finish. Rounded edge is a type of edge treatment where the sharp corners of the coil are rounded off to reduce the risk of injury and improve handling.

- Q: How are steel coils used in the production of automotive components?

- Steel coils are used in the production of automotive components through a process called stamping, where the coils are fed into a machine that cuts and shapes the steel into various parts such as body panels, chassis components, and engine parts. These steel components are then assembled to create the final automotive product.

Send your message to us

GI/Hot DIP Galvanized Steel Coils Regular 1000mm 1219mm 1250mm Z60-Z120 Dx51d+Z, DC01

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords