Hot DIP Galvanized Steel Coils Regular 1000mm 1250mm/PI

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

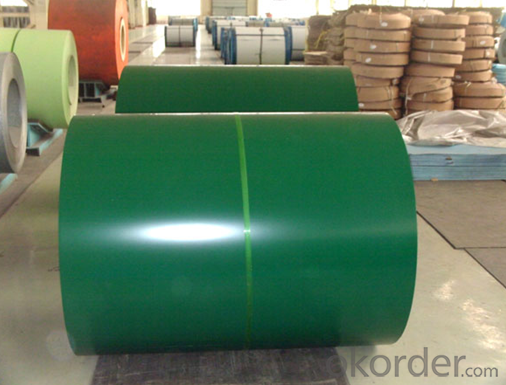

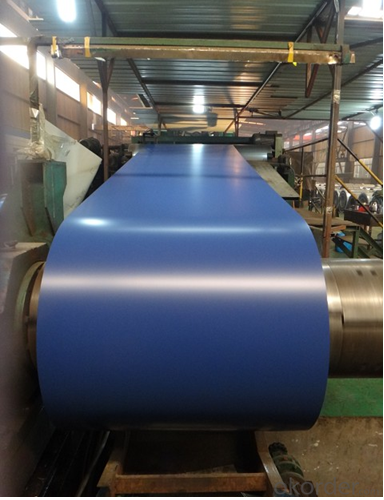

Hot DIP Galvanized Steel Coils Regular 1000mm 1250mm Z60-Z120 Dx51d+Z, DC01

Product Description

Description:

EN 10147 Structure hot dip galvanized steel coil S250GD+Z, S350GD+Z (SGC340, SS275, SS340)/Custom Deep drawing hot dip galvanized steel coil DX52D+Z, DX53D+Z, S

Galvanized steel is taken cold rolled steel as the base metal, after continuous hot dip galvanizing process, the product produced is an excellent resistance to atmospheric corrosion coating steel coil, as the steel gets coated in layers of zinc and rust won't attach this protective metal; Cold rolled plate by hot-dip galvanizing may extend the service life of 15-20 years.

For countless outdoor, marine, or industrial applications, galvanized steel is an essential fabrication component. Hot dip galvanized steel is used in applications where steel may be exposed to weather, but where stainless steel is too expensive.

Application:

Construction

Manufacture anticorrosion, industrial and civil architecture roof boarding, roof grille

Light industries

Home appliance's case, civil chimney, kitchen utensils

Auto industry

Corrosion resistant parts of cars

Agriculture

Food storage, meat and aquatic products' freezing and processing equipment

Commerce

Equipments to store and transport materials, and packing implements

andard | EN 10142 | DX51D+Z, DX52D+Z, DX53D+Z |

JIS G3321 | SGCC, SGCD, SGCDD, SGC400 | |

ASTM A792M | CS type C, CS type B, DS, SS250 | |

Base Metal | Cold rolled steel coils SPCC, SPCD, SPCE, DC01, DC03, DC04, CS, DS, DDS, Q195, Q250, Q350 | |

Thickness | 0.14mm-3.0mm | |

Width | 600mm-1600mm | |

Coil ID | 508mm, 610mm | |

Zinc coating | 60g/m2-450g/m2 | |

Surface treating | chromium free passivation, chromium passivation, fingerprint resistant, oiled | |

Spangle types | Minimal spangle, zero spangle, regular and big spangle | |

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

- Q: How are steel coils used in the production of pipes?

- Steel coils are used in the production of pipes by being uncoiled and then passed through a series of forming and welding processes. The coils are flattened and shaped into the desired pipe size and then welded together to create a continuous length of pipe.

- Q: What products can we make with steel (eg Steel strip, rod, bar, rail, tube) How are these made? What can we make from these steel products?Can you please make the answers as detailed as possible you can because i really want to know this really well. Thank you.

- Your okorder (they make steel deck and steel joists) There are thousands of other items routinely produced from steel, including rebar, and all the metal in cars, airplanes, and about a million other things.

- Q: What are the different methods of tension leveling for steel coils?

- There are several methods of tension leveling for steel coils, each with its own advantages and applications. 1. Roller leveling: This method involves passing the steel coil through a series of rollers under high tension. The rollers are strategically positioned to apply pressure on the coil, effectively stretching and elongating it. Roller leveling is commonly used for thinner gauge coils and is effective in removing coil set, crossbow, and edge wave defects. 2. Stretch leveling: In this method, the steel coil is subjected to a combination of tension and elongation. The coil is gripped by clamps at both ends and then stretched using hydraulic or mechanical devices. This process helps to remove residual stresses, flatten the coil, and improve shape control. Stretch leveling is particularly suitable for thicker gauge coils and can effectively eliminate wavy edges and center buckle. 3. Temper rolling: This method involves passing the steel coil through a series of temper rolls, which apply pressure on the surface of the coil. Temper rolling is primarily used to improve the surface finish of the steel and enhance its mechanical properties. It can also help to reduce coil set and improve flatness. 4. Skin pass rolling: In this method, the steel coil is passed through a series of rolls that apply a light pressure on the surface. Skin pass rolling is typically performed after the primary leveling process to further improve surface finish, enhance flatness, and reduce surface defects such as scratches or marks. 5. Stretcher leveling: This method involves clamping the steel coil at both ends and then applying tension to stretch it. The stretched coil is then held in this position for a period of time to allow for stress relief and shape correction. Stretcher leveling is commonly used for thicker gauge coils and can effectively remove coil set, crossbow, and center buckle. Each of these tension leveling methods offers unique advantages and is suitable for different types of steel coils and specific requirements. The choice of method depends on factors such as coil thickness, desired flatness, surface finish, and the specific defects that need to be corrected.

- Q: What are the common manufacturing defects in steel coils?

- Common manufacturing defects in steel coils include surface defects such as scratches, pits, and dents, as well as internal defects like inclusions, cracks, and voids. Other common defects can include uneven thickness, waviness, and coil set.

- Q: How are steel coils used in the manufacturing of elevator components?

- Steel coils are used in the manufacturing of elevator components as they provide a high strength material that can be shaped and formed into various parts such as brackets, frames, and supports. These coils are typically processed and cut into the required sizes and shapes before being further fabricated and assembled into elevator components, ensuring the necessary structural integrity and durability for safe elevator operation.

- Q: What are the common coil thickness and width combinations available for steel coils?

- The common coil thickness and width combinations available for steel coils can vary depending on the specific requirements and standards of the industry. However, there are some commonly found combinations that are widely used. In terms of coil thickness, common options range from thin to thick coils. Thin coils typically have a thickness ranging from 0.4mm to 3.0mm, while medium thickness coils can be around 3.0mm to 6.0mm. For thicker coils, the range can be from 6.0mm to 25.0mm or even higher, depending on the specific application. Regarding coil width, it also varies based on the intended usage. Some common options include coils with widths of 600mm, 750mm, 900mm, 1000mm, 1200mm, 1250mm, and 1500mm. However, wider or narrower coils can also be available depending on the specific requirements of the customer or industry. Ultimately, the most suitable coil thickness and width combination will depend on factors such as the intended application, manufacturing processes, transportation limitations, and customer preferences. It is essential to consult with steel coil manufacturers or suppliers to determine the most appropriate options for your specific needs.

- Q: Is there any noticable or perceived difference between smoking out of a pipe with a brass screen and a stainless steel screen?

- Its not a good idea to make the whole thing of metal. Metal is a good conductor of heat and its bound to get too hot for you lips during sustained use. Thats assuming your going to smoke tobacco with it. If you plan on smoking small hits of a particular substance then it may be alright. Mind you pipes are poor choice for this kind of smoking. So sticking with the tobacco pipe I would make it out of wood or talc not metal.

- Q: They both sell the same thingIf prices are to high companies won't by the steelIf prices are to low then the steel company won't earn enoughWhy are some steel companies more successful than others

- Steel is a global commodity. There is some variety in product (flat rolled, tubing, etc), but basically the same product worldwide. Cost to the customer includes shipping of a very heavy product. Inputs are also heavy and costly to ship. Inputs: - Coal - Iron Ore. Some firms have the ability to recycle old steel, a competitive advantage. - Energy (very energy intensive industry) - Labor - Machinery. A new blast furnace is more efficient than 50 years old. So the most profitable steel firms have some of these characteristics: - Proximity to raw materials - Proximity to customers - Access to cheaper means of transportation; rail and sea - Newer machinery - Cheaper labor force - Reasonable cost for electricity and fuel for furnaces

- Q: hi i was doing a little history project on guns. i was just wondering if anyone could help me find out what material was used before steel and why this material wasnt as good as steel ( its faults)thanks for your help

- The most common was bronze, which was the strongest material that could be cast, at least until the industrial revolution. Until that time, furnaces which could reach temperatures hot enough to melt steel did not exist. The only way to work with steel would have been forging, which means hammering it into shape while red-rot. Obviously, this is not a very practical method for making large thick-walled cannons (though it was done on occasion. Small arms such as pistols and muskets could be easily made of steel by hand forging.) The most practical way to make cannons was pouring molten bronze which melts at significantly lower temperature than steel. Cast iron was also used. Note that Cast Iron contains 3%-7% carbon, compared to steel which only contains between 2% to 0.2% carbon. Due to the excessive carbon content of cast iron, it's melting point is about 500 degrees lower than steel enabling it to be melted with pre-industrial furnaces. Unfortunately, cast iron is also brittle, unlike steel or bronze. This means that a defective or cracked casting could easily explode, sending iron shrapnel everywhere. (Also, maiming and killing the gun crew, an experienced gun crew was as valuable as the cannon itself!) For this reason. Cast iron cannon were usually considered a cheap, risky alternative to expensive but durable bronze.

- Q: Question about steel type used in bridges.?

- It is used for other things besides bridges and that might be a bad use. Corten was used for very tall light standards in the Fort Worth Water Gardens with the clear understanding that it was to be kept dry. As time passed and personnel changed, somebody decided the round base with bolts sticking up was ugly and put dirt and plantings in the basin in the concrete holding the poles. The watering of the plants kept the rust going through the steel and one pole eventually fell, killing two people. The other light poles were removed.

Send your message to us

Hot DIP Galvanized Steel Coils Regular 1000mm 1250mm/PI

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords