Hot-Dip Galvanized Steel Coil with Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Hot-Dip Galvanized Steel Coil Description:

Hot-dip galvanized steel coil are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial application.

2.Main Features of the Hot-Dip Galvanized Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

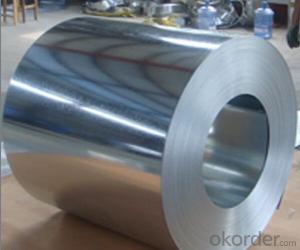

3.Hot-Dip Galvanized Steel Coil Images

4.Hot-Dip Galvanized Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: SPCC, SPCD, Q195, DX51D

Thickness: 0.15-5.0mm

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Galvanized

Application: Container Plate

Special Use: High-strength Steel Plate

Width: 600-1250mm

Length: depends

commodity: hot dipped galvanized steel coil

technique: cold rolled

thickness: 0.15-5.0mm

width: 600-1500mm

surface treatment: galvanized

zinc coating: 50-275g/m2

coil weight: 3-7 tons

coil ID: 508/610mm

spangle: zero spangle, regular spangle, small spangle, big spangle

payment term: by L/C or T/T

5.FAQ of Hot-Dip Galvanized Steel Coil

What’s the application of this product?

There are many applications for this product. For example, roofing, cladding, decking, tiles, sandwich walls, etc.

What’s the coating composition of Hot-Dip Galvanized Steel Coil?

The coating composition is 55% aluminium in weight ratio, 43.4% zinc, and 1.5% silicon, with excellent corrosion and heat resistance performance.

- Q: What is the lifespan of steel coils?

- The lifespan of steel coils can vary depending on various factors such as the quality of the steel, its usage, maintenance, and environmental conditions. However, with proper care and maintenance, steel coils can typically last for several decades.

- Q: How are steel coils used in the manufacturing of lighting fixtures?

- Steel coils are commonly used in the manufacturing of lighting fixtures as they provide a sturdy and durable framework for the fixtures. The coils are often shaped and welded to create the desired structure, ensuring that the lighting fixtures are robust and can withstand various installation environments. Additionally, steel coils can be coated or painted to enhance the aesthetics of the fixtures, making them more visually appealing.

- Q: I own a crappy steel string acoustic and a very nice electric guitar.I have saved up to buy a new acoustic but I cannot decide to just invest in a better steel string or explore around with a nylon string. From others experience, will I get my fill of satisfaction of playing on a nylon, or should I stick to a steel string?

- Nylon is easy to use for beginners but steal sounds better.

- Q: How are steel coils used in the production of bridges and infrastructure?

- Steel coils are an essential component in the production of bridges and infrastructure. These coils are made from steel, which is a strong and durable material that can withstand heavy loads and harsh environmental conditions. In bridge construction, steel coils are used to manufacture the structural components such as beams, girders, and columns. These components provide the necessary strength and support to the bridge, allowing it to carry the weight of vehicles, pedestrians, and other loads. Steel coils are rolled into the desired shape, cut to the required length, and then welded or bolted together to create these structural elements. Additionally, steel coils are also used in the fabrication of bridge decks, which are the roadways or walkways on the bridge. These coils are processed to form steel plates, which are then assembled and secured onto the bridge structure. The steel plates provide a smooth and durable surface for vehicles and pedestrians to travel on. In terms of infrastructure, steel coils play a vital role in the construction of various structures such as buildings, stadiums, and industrial facilities. They are used to fabricate the primary support systems, including columns, beams, and trusses, which provide the necessary strength and stability to these structures. Steel coils are also used to create roofing and cladding systems, ensuring protection against weather elements and enhancing the overall aesthetics of the infrastructure. Furthermore, steel coils are often used in the production of reinforcing bars, commonly known as rebar. Rebar is essential for reinforcing concrete structures such as foundations, walls, and slabs. These coils are processed into various sizes and shapes, and then embedded within the concrete to increase its tensile strength and prevent cracking or collapsing under heavy loads. Overall, steel coils are a critical component in the production of bridges and infrastructure. Their strength, durability, and versatility make them an ideal material for constructing safe and reliable structures that can withstand the test of time.

- Q: Is it faster to smith steel or mithril in Rinescape assuming I'm going to mine everything myself?Mining level: 76Smithing level: 55

- steel, it will take you way to long to mine mithril ore, and all the coal. also if you make steel plate bodies they actually sell becuase people use it to make steel titian pouches

- Q: How do steel coil manufacturers meet customer specifications?

- Steel coil manufacturers meet customer specifications by following a comprehensive and systematic approach that involves various stages and processes. Here are some key steps they take: 1. Understanding customer requirements: Manufacturers initiate the process by thoroughly understanding the specific requirements of their customers. This includes determining the desired dimensions, tolerances, mechanical properties, surface finish, and any other specific characteristics needed. 2. Material selection: Based on the customer's requirements, manufacturers select the appropriate type and grade of steel to meet their specifications. This involves considering factors such as strength, corrosion resistance, formability, and cost-effectiveness. 3. Production planning: Manufacturers carefully plan their production processes to ensure that customer specifications are met. This involves determining the appropriate manufacturing techniques, equipment, and resources required. 4. Coil processing: Steel coils are processed through various stages such as hot rolling, cold rolling, annealing, pickling, and coating, depending on the customer's specifications. Each step is carefully controlled to achieve the desired properties and dimensions. 5. Quality control: Throughout the manufacturing process, strict quality control measures are implemented to ensure that the coils meet the customer's specifications. This includes regular inspections, testing, and compliance with industry standards. 6. Customization and flexibility: Steel coil manufacturers often offer customization options to meet specific customer needs. They have the capability to adjust the thickness, width, and length of the coils to match the desired specifications. 7. Communication and collaboration: Effective communication and collaboration between the manufacturer and the customer are crucial to meeting specifications. Manufacturers work closely with their customers to address any concerns or modifications required during the manufacturing process. 8. Documentation and certification: Once the steel coils are manufactured, manufacturers provide detailed documentation and certifications to ensure traceability and compliance with customer specifications. This includes providing test reports, material certificates, and any other necessary documentation. By following these steps, steel coil manufacturers can consistently meet customer specifications, ensuring that the final product meets the desired requirements and quality standards.

- Q: I was wondering because i just watched an episode of build it bigger on the discovery channel about the uss George bush, and when they were discribing it they said it was 500 tons of steel and 47,000 tons of aluminum. this kinda struck me as odd because i thought that it was mostly made of steel. and i would think that even if it was mostly aluminum, that the hull would be steel. and i think the hull would weigh more than 500 tons.

- An aircraft carrier is a pretty large hunk of metal. And it's mostly steel... at least its structure and weight bearing surfaces. As I recall, there was quite a bit of aluminum and other light stuff used for cosmetic stuff, like covering on interior bulkheads (walls). But the flight deck is about three football fields of steel... thick steel. Planes landing on an aircraft carrier don't land. They are trapped when their tail hook grabs an arresting cable, and kind of fall out of the sky. When they hit, they need something pretty substantial to break the fall. A carrier displaces an awful lot of water, but, and this is a guess, probably less than 100,000 tons... the one I was on displaced less than 80,000 tons. About 40 feet of it is underwater. Most of its crew live below or very close to the waterline. But there's enough above water to allow for the city that the carrier contains to operate pretty much like any city with a population of about 6,000. It has stores where you can buy almost anything, barbers, a hospital, dentists, doctors, fitness center, theaters, fast food places where you can have a hamburger made to order, restaurants where the food is free, a post office, gas stations, a radio studio and a television studio, newspaper, churches--a chapel as well as other places people can meet to hold religious services, even an airport. I looked at the ship's website. From what little information there is, it looks to be just a few feet larger than the old carrier I was on. If it weighs 500 tons, it has to displace 500 tons. Don't ask me how they do it... unless it was materials used during construction and removed.

- Q: How are steel coils used in the manufacturing of defense equipment?

- Steel coils are used in the manufacturing of defense equipment for various applications such as armor plates, vehicle components, and weapon systems. The coils are typically processed and shaped into specific forms to provide strength, durability, and protection required for military purposes.

- Q: The steel is orangish in colour and is mostly made of copper

- Steel is an alloy of iron and carbon and optionally one or more of numerous other materials. Copper is normally not used, except sometimes in small percentages. Steel is never yellow or orange in color. Reactivity of steel depends on the materials it is alloyed with. Chromium and nickel with steel make stainless steel, which is much less prone to reactive than iron. .

- Q: How are steel coils used in the production of automotive components?

- Steel coils are used in the production of automotive components through a process called stamping, where the coils are fed into a machine that cuts and shapes the steel into various parts such as body panels, chassis components, and engine parts. These steel components are then assembled to create the final automotive product.

Send your message to us

Hot-Dip Galvanized Steel Coil with Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords