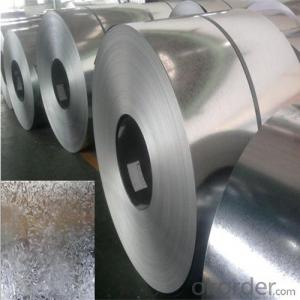

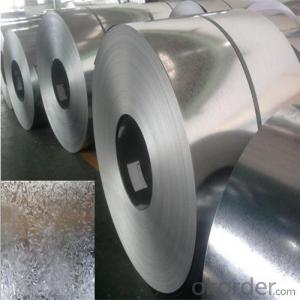

HOT-DIP GALVANIZED STEEL COIL WITH SUPER HIGH QUALITY

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details | |||||

Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | SGCC,DX51D/DX52D/S250,280GD | Thickness: | 0.12-4.0 mm |

Place of Origin: | Brand Name: | N/M | Model Number: | ssp-226 | |

Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | galvanized/ Galvalume/zinc coatting |

Application: | strong anti-corrosion ability,cold bending molded manufacturablity | Special Use: | High-strength Steel Plate | Width: | 600-1250 mm |

Length: | in coil | product: | g40 prime/secordary hot-dip galvanized cold rolled steel coil/sheet | ||

Packaging & Delivery | |||||

Packaging Detail: | standard export package,Other types of packing can be customized as per client's requirement. | ||||

Delivery Detail: | as per client's requirements | ||||

Specifications

1.Mateials:SGCC,DX51D / DX52D / S250,280GD

2.Size:width:600-1250mm(900mm,1215mm,1250mm,1000mm the most common)

thickness:0.15-2.0mm

length:1000-6000mm,as your require

3.Zinc coating :60-180g( as required)

4.Coil id:508mm

5.Coil weight: 3-5MT(as required)

6. Surface:regular/mini/zero spangle, chromated, skin pass, dry etc.

7. Application:

With excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils.

8.Packaging Details:

Standard export package.

Other types of packing can be customized as per client's requirements.

- Q: How are steel coils used in the production of electrical motors?

- Steel coils are used in the production of electrical motors as they serve as the core component of the motor's electromagnetic system. These coils are wrapped around an iron core, creating an electromagnetic field when electricity flows through them. This electromagnetic field generates the necessary force that allows the motor to convert electrical energy into mechanical energy, enabling the motor to function and perform various tasks.

- Q: How are steel coils inspected for oil or rust residues?

- Oil or rust residues in steel coils are examined through a series of visual and physical checks. Trained personnel conduct the initial visual inspection, closely scrutinizing the steel surface for any indications of oil or rust residues. They look for discolouration, stains, or any unusual signs that could suggest the presence of contaminants. Besides the visual inspection, different techniques are employed to detect oil or rust residues. One commonly used method is solvent cleaning. A solvent is applied to the steel coil's surface, and if there are any oil or rust residues, they will dissolve and become visible. This enables inspectors to identify and eliminate any contaminants. Ultrasonic testing is another technique used for inspection. Ultrasonic waves are transmitted through the steel coil, and any variations in the reflections of these waves can indicate the presence of oil or rust residues. This non-destructive testing method provides a more comprehensive analysis of the steel's condition, ensuring a thorough inspection. In addition, specialized equipment such as magnetic particle inspection or eddy current testing may be utilized. Magnetic particle inspection involves applying magnetic particles to the steel surface, which will gather around areas with oil or rust residues. Similarly, eddy current testing employs electromagnetic induction to identify surface irregularities caused by contaminants. Overall, a combination of visual inspection and various testing techniques is employed to ensure a meticulous examination of steel coils for oil or rust residues. These rigorous inspections guarantee that the coils meet the required quality standards and are free from any contaminants that may compromise their performance or durability.

- Q: What are the different types of steel coil surface treatments for corrosion resistance?

- To enhance corrosion resistance, different methods are utilized for treating the surface of steel coils. These treatments create a protective layer that prolongs the lifespan of the steel and prevents corrosion. Some commonly used treatments for corrosion resistance include: 1. Galvanizing: Widely recognized as an effective method, galvanizing involves applying a layer of zinc to the steel coil's surface. The zinc acts as a sacrificial anode, corroding before the steel, thus safeguarding it against rust and corrosion. 2. Chromate conversion coating: This treatment entails applying a chromate-based solution to the steel coil's surface. The chromate forms a thin film that serves as a protective barrier against corrosion. Moreover, it improves the adherence of paint or other coatings that may be applied subsequently. 3. Phosphating: Phosphating is a process where a phosphate coating is added to the steel coil. This coating establishes excellent corrosion resistance by chemically bonding with the steel surface. It also enhances the adherence of subsequent coatings or paints. 4. Organic coatings: These coatings comprise paint or epoxy and are applied to the steel coil to create a barrier between the steel and its surroundings. They offer corrosion resistance and enhance aesthetic appeal. The selection of organic coating depends on the specific application and the desired level of corrosion protection. 5. Zinc-rich paint: Similar to galvanizing, zinc-rich paint contains a high concentration of zinc particles. When applied to the steel coil, these particles provide sacrificial protection, preventing corrosion. This coating is commonly employed in harsh environments or for steel coils exposed to frequent moisture or saltwater. It is important to consider various factors such as the application, environment, budget, and required level of corrosion resistance when choosing a surface treatment. Consulting with a steel coil manufacturer or corrosion specialist is advisable to determine the most suitable treatment for a specific situation.

- Q: How are steel coils processed for different levels of hardness?

- Steel coils can be processed to achieve different levels of hardness through a variety of methods. One common method is heat treatment, which involves heating the coils to a specific temperature and then rapidly cooling them to alter their microstructure and achieve the desired hardness. The process of heat treatment can include quenching, tempering, or annealing, depending on the desired hardness level. Quenching involves cooling the coils rapidly in a liquid medium such as water or oil to achieve a high hardness level. Tempering, on the other hand, involves reheating the coils to a lower temperature and then slowly cooling them to achieve a desired balance of hardness and toughness. Annealing is a process that involves heating the coils to a specific temperature and then slowly cooling them to relieve internal stresses and achieve a softer and more ductile material. Additionally, mechanical processes such as cold rolling or cold working can also be used to increase the hardness of steel coils. These processes involve subjecting the coils to compressive forces, which cause the material to deform and result in an increase in hardness. Overall, the processing of steel coils for different levels of hardness requires careful control of temperature, cooling rate, and mechanical forces to achieve the desired properties for specific applications.

- Q: i have recently gotten into DIY and am planning on making my own knife. My question is what kind of steel would be good to use for heat treating if i plan on using water and not oil in the process.

- Go to junkyard get old leaf spring, cut out knife, start sharpening. Why waste time heat treating steel when the spring steel as already be done.

- Q: How are steel coils used in the manufacturing of consumer goods?

- Steel coils are used in the manufacturing of consumer goods as a primary material for various applications. They are commonly used in the production of appliances, automotive parts, construction materials, and packaging materials. The coils can be shaped, cut, and formed into different components or structures, providing strength, durability, and versatility to the end products.

- Q: hello, I am trying to figure out what wok to get and came across a website that offers many woks out of different materials. what is the best, or considered original (traditional)? I have a couple of cast iron pots and pans - too heavy, so I am assuming it will take some time for a cast iron wok to heat up. what about carbon steel and stainless steel? Thanks

- Traditionally woks do take a long to heat up but the trick is that they hold the heat for a long time, so either stainless steel for convenience or cast iron for tradition. Don't use anything non stick, chinese cooking uses a lot of oil, the non-stick will just be unhealthy when it starts to burn off. The cast iron will be good because it'll heat up and keep its heat, in chinese homes that have the wok, the wok usually gets heated up throughout a few hours, you need it to be really hot all the way through all over the pan to do chinese cooking. also traditionally woks are built into home or are big and positiioned over a fire not to be moved too much, the point is to keep stiring and stiring and stiring until your food is cooked.

- Q: What are the safety precautions to be followed while handling steel coils?

- To prevent accidents and injuries when dealing with steel coils, it is crucial to adhere to specific safety measures. Here are some safety measures that must be observed: 1. Personal Protective Equipment (PPE): Always wear suitable PPE, including safety glasses, gloves, steel-toed boots, and hard hats. These items serve to shield you from potential dangers such as falling objects, sharp edges, and chemicals. 2. Proper Lifting Techniques: Employ correct lifting techniques to avoid strains and back injuries. Lift using your legs, not your back, and refrain from making sudden or twisting movements while handling the coils. If the coils are excessively heavy or cumbersome to lift manually, resort to mechanical lifting equipment such as forklifts or cranes. 3. Secure Storage: Ensure that steel coils are stored securely and stably to prevent them from falling or rolling over. Make use of appropriate racks, shelves, or storage containers specifically designed for steel coils. Keep the storage area clean, organized, and devoid of obstructions. 4. Handling Tools: Utilize appropriate handling tools like coil hooks, lifting clamps, or coil tongs to firmly grasp the steel coils. Avoid using makeshift or improper tools, as they can cause the coils to slip, leading to accidents. 5. Secure Transportation: Prior to transporting steel coils, ensure that they are adequately secured on the truck or flatbed. Utilize suitable tie-downs, straps, or chains to prevent the coils from shifting or falling during transit. Adhere to all transportation regulations and guidelines to ensure safe transportation. 6. Awareness of Surroundings: Maintain awareness of your surroundings and the presence of other workers or equipment in the vicinity. Keep a safe distance from moving machinery, forklifts, or other vehicles to avoid collisions or accidents. 7. Hazard Communication: Train all employees handling steel coils on proper safety procedures and ensure that they comprehend the potential hazards involved. Display safety signs or labels to indicate the presence of heavy loads or hazardous materials. 8. Regular Maintenance: Regularly inspect and maintain equipment such as lifting devices or storage racks to ensure they are in proper working condition. Promptly report any defects or malfunctions to the relevant personnel for repairs. By adhering to these safety precautions, the risk of accidents, injuries, and damage when handling steel coils can be minimized. Prioritizing safety in the workplace is crucial to safeguarding yourself and your colleagues.

- Q: Explain why a steel nail sinks but a steel ship floats.

- surface area of the ship against the water is much greater than the nail.

- Q: Are steel coils used in agricultural equipment manufacturing?

- Yes, steel coils are commonly used in agricultural equipment manufacturing. Steel coils are used to create various components such as frames, brackets, and supports, which are essential for the construction and durability of agricultural equipment. The strength and versatility of steel make it a preferred material choice for manufacturing agricultural machinery.

Send your message to us

HOT-DIP GALVANIZED STEEL COIL WITH SUPER HIGH QUALITY

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords