Hot-Dip Galvanized Steel Sheet of Good Qualities

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

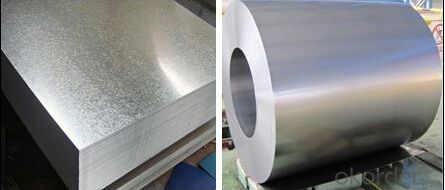

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Packing: Standard seaworthy export package

Technology test results:

Processability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the factors affecting the strength of steel coils?

- The factors affecting the strength of steel coils include the composition of the steel, the manufacturing process used, the temperature and time of heat treatment, the presence of impurities or defects, and the degree of deformation during processing.

- Q: The stainless steel drinking fountain had a little acid on it and rusted. I need to restore it. Is this possible?

- Nope, stainless steel is actually coated steel that can be removed by acid or scrubbing too much. it would need to be re dipped to go back to normal. would cost a fortune however.

- Q: What minerals are mixed to make steel?

- It depends on the type of steel that you want. For example- A cold drawn carbon steel spring wire consists of Carbon,Silicon,Manganese,sulphur potassium. If you want to make an alloy steel you can also add chrome,vanadium , nickel etc. It depends on the combinations and percentages of each used.

- Q: Can someone help me...i have a diagram and were supposed to calculate the steel tonnage needed for the pictre. Can someone tell me step by step what i need to do (ex:find area of ...)

- - Find the cross sectional area of the steel bars if given, if not find the volume of concrete and approximately multiply the concrete volume by 400kg the weight of steel per concrete volume. - If you find the steel cross sectional area , multiply by the

- Q: During fatigue testing of any material (especially for steels), why is strain-control mode preferred over stress control mode?

- because metals, like steel, are ductile and will stretch before breaking. Straining the metal is stretching it, stressing the metal is applying a shearing force or bending until there is an actual metal failure. A sheet metal strap 1inch across and 24 gauge metal is commonly used to support metal ducting systems in construction. These have an average strain to failure weight load as high as 16,200 lbs. As reported by the smacna index, they will safely hold 6800 pounds. Of more interest is the screws used to hold the strap to the duct. While they are grade 3, fairly strong, they strain to 1400 pounds when properly installed, and are safely able to support 650 pounds, unless they are overtorqued (stripped) and this quickly drops to 400 pounds and 125 pounds...big difference.

- Q: what do you think about producebility of low density steel? for example: can density of 1020 steel (or ony others) be decreased without any loss of other properties.

- If a material has a lower density than steel, then it isn't steel.

- Q: How are steel coils used in the construction of buildings?

- Steel coils are used in the construction of buildings for various purposes such as structural support, reinforcement, and as raw materials for manufacturing components like beams, columns, and steel plates. The coils are often transformed into different shapes and sizes through processes like cutting, bending, and welding to meet specific construction requirements. They provide strength, durability, and stability to building structures, making them a crucial element in the construction industry.

- Q: I know that carbon steels and alloy steels are different but are carbon steels still alloys?Thanks!

- Yes. it's an alloy of iron and carbon. Carbon steel can either mean plain carbon steel which is steel that doesn't have significant amounts of other elements, like chromium, manganese, or molybdenum. It can also be used to refer to ANY steel that is NOT a stainless steel. Alloy steel is any steel that has greater than 1% of other elements added to it besides carbon. Stainless steel might be in a certain sense be considered alloy steel but I think most people in the steel business consider it as it's own separate material from carbon steels. Many stainless steels contain only trace amounts of carbon, so they should rightly be considered iron-chromium alloys, not steel, which by default refers to iron-carbon alloys. Note that nearly all modern carbon steels also contain 0.2%-0.5% manganese and silicon. Even steels that are otherwise considered plain carbon and not alloy steels. Mn and Si are added because they prevent defects in cast steel ingots, and hot rolled items like billets and plates. However at low levels they don't affect the properties of the steel greatly.

- Q: How do steel coils contribute to earthquake resistance in structures?

- Steel coils contribute to earthquake resistance in structures by providing strength and flexibility. When used in the construction of buildings, steel coils can absorb and dissipate the energy generated by an earthquake, preventing it from causing significant damage. The high tensile strength of steel allows it to withstand the lateral forces and vibrations during an earthquake, ensuring the structural integrity of the building. Additionally, the ductility of steel allows it to bend and deform without breaking, further enhancing its ability to withstand seismic activity.

- Q: How are steel coils used in the production of elevator components?

- Steel coils are an essential component in the production of elevator components. These coils are made from high-quality steel that is specifically designed to meet the demanding requirements of elevator manufacturing. One of the primary uses of steel coils in elevator production is for the manufacturing of elevator doors. The coils are processed into flat sheets and then cut into the desired dimensions to create the doors. These doors require strength and durability to withstand frequent use and ensure passenger safety. Steel coils provide the necessary structural integrity and resistance to deformation that is necessary for elevator doors. Additionally, steel coils are also used in the manufacturing of elevator cabins. The coils are processed and formed into various shapes to create the walls and flooring of the elevator cabins. The strength and rigidity of steel make it an ideal material for this purpose, as it can withstand heavy loads and provide a secure and stable environment for passengers. Moreover, steel coils are used in the production of elevator shafts. The coils are rolled into cylindrical shapes and welded together to create the structural framework of the elevator shafts. These shafts need to be strong and rigid to support the weight of the elevator and ensure smooth and safe vertical movement. Steel coils provide the necessary strength, stability, and load-bearing capacity for this critical component of elevator systems. In summary, steel coils are vital in the production of elevator components such as doors, cabins, and shafts. Their strength, durability, and versatility make them suitable for creating reliable and safe elevator systems that can transport passengers efficiently and securely.

Send your message to us

Hot-Dip Galvanized Steel Sheet of Good Qualities

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords