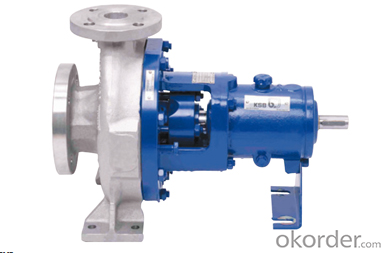

Horizontal, radially split volute casing pump CPKN

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Design |

Overview of technical data

| Type of impeller | Closed; Radial |

| Type of installation | Long- coupled |

| Maximum drive rating | 3. 200 kW |

| Impeller material (EN standard) | NORIDUR 1. 4593;JL 1040;1.4408 |

| Type of bearing | Rolling element bearings |

| Drive frequency | 50 Hz / 60 Hz |

| Maximum speed of rotation | 3. 500 1/min |

| Maximum flow rate | 4. 800 m³/h |

| Maximum discharge-side pressure | 25 bar |

| Casing material (EN standard) | NORIDUR 1. 4593;1.4408;JS 1025;GP240GH+N |

| No. of impeller entries | Single entry |

| Casing material | Cast stainless steel; Ni-Resist;Cast duplex steel;Cast steel;Nodular cast iron |

| Minimum flow rate | 1 m³/h |

| Suction characteristics | Non- priming |

| Drive voltage | Low voltage |

| eClass assignment | 36410000; 36410100;36410101 |

| Pull-out design | Yes |

| Pump set location | Dry installed |

| Heatable | Yes |

| Max. permissible fluid temperature | 400 ****** |

| Main applications | Energy; Industry and process engineering |

| Type of installation | 00 |

| Type of casing | Volute casing |

| Type of connection | Flange |

| Type of lubrication | Oil lubrication |

| Type of drive | Electric motor |

| Installation position | Horizontal |

| Shaft material (EN standard) | 1. 4462;1.5680;C 45+N;1.7709 |

| Type of coupling | Direct |

| Shaft seal type | Mechanical seal |

| Maximum head | 275, 00 m |

| Maximum rated pressure (discharge) | PN 25 |

| Minimum head | 2, 00 m |

| Standard | ISO 5199; ISO 2858;EN 22858 |

| Nozzle position | End suction |

| Casing partition | Radially split |

- Q: Know flow and lift how to calculate the pump power?

- P: the density of refrigerant, when the working fluid is water, P =1ETA - pump efficiency, can not find desirable value =0.8N=30x (200/3600) x9.81x1/0.8=20.44 = 20 (kW)(that is, 20kW motors)

- Q: What are the general water pump failure, how to repair?

- (2) in contact with the water pump inlet of the horizontal application of reverse flow direction, fell more than 0.5% slope, connect one end of the highest import pumps, do not completely level. If the upward tilt, the intake pipe will retain air, reducing the water pipes and pumps in the vacuum, water absorption.

- Q: What is a gear pump for?

- Oil pump casing wearIt is mainly the wear of the floating sleeve hole (the normal clearance between the gear shaft and shaft sleeve is 0.09~0.175mm, and the maximum shall not exceed 0.20mm). The gear work is affected by the pressure oil, the gear tip is close to the oil pump casing, and the low pressure chamber part of the pump body is worn. Another kind of wear is the circumferential wear of the work surface in the shell. This kind of wear is mainly caused by the addition of oil which is not clear, so the oil without impurities is necessary.

- Q: Water pump can not be pumped out, how to maintain water?

- Water pump does not suck or does not drain:The causes for the valve stuck, part of the blockage of water, high water or water leakage is too high, may also turn right, impeller blockage. After checking through them one by one, can be taken at the end of valve repair, clear blockage and correct steering, cleaning and other measures to deal with the impeller.The purpose of the work is to pump water from one place to another, or increase the pressure to control the mechanical energy into fluid energy.

- Q: What does "efficiency" mean in a water pump catalog?

- The efficiency of the water pump nameplate refers to the maximum efficiency that the pump can reach at the rated speed

- Q: What is the function of a submersible pump?Do you have any knowledge about submersible pumps?.

- Submersible pumpThe submersible pump is composed of a control cabinet, submersible cables, water pipes, submersible pumps and submersible motors.Submersible pump main application and scope of applicationIncluding mine rescue, construction, drainage, agricultural irrigation and drainage, industrial water recycling, urban and rural residents cited water supply, and even rescue, disaster relief and so on.Classification of submersible pumpsAs far as media is concerned, submersible pumps can be broadly divided into three categories: clean water submersible pumps, sewage submersible pumps, sea water submersible pumps (corrosive).

- Q: Bolus dosage of infusion pumpWhat is the purpose of the pill dose control in the special safety standard for infusion pumps? If the risk is not properly controlled, what is the degree of risk? And how can the open infusion pump be used in this regard?

- Four) release bolus dosage method can use automatic release and manual release two ways, the key is to alarm after the infusion must be stopped(five) any kind of pill dose release are not restricted to replace the pill. The total dose limit for in pipe blockage after pill agglomeration process will remove blocking accident, this time will be the rapid infusion of pill dose concentration into the patient's blood, if the total dose pill does not get test and limit, rapid infusion of this accident it may have unimaginable consequences.(six) supplies open type infusion pump overflow on the domestic market for pill characteristic parameters of consumables simply without testing and limitation. Therefore, the risk of accidental pill has become one of the residual risk of open type infusion pump supplies the most deadly.

- Q: Is the sewage pump the same as the mud pump?

- Sewage pump is mainly used for industrial wastewater treatment, sewage treatment, environmental protection has played a big role. Among them, the sewage pump is also a sewage pump with cutting wheel, such sewage pump can be chopped dirt, and then extract the sewage clean.

- Q: What is an industrial water pump?

- Industrial water pump, water pump for industrial production.A pump is a machine that transports liquids or pumps liquids. It will be the prime mover of the mechanical energy or other external energy transfer to the liquid, the liquid energy increase, mainly used to transport liquids including water, oil, alkali liquid, emulsion, suspension emulsion and liquid metal, but also transport liquid, gas mixtures and liquids containing suspended solids. Pump performance of technical parameters are flow, suction, lift, shaft power, water power, efficiency, etc.; according to the different principles of work can be divided into volume pumps, vane pumps and other types. Displacement pump is to use its studio volume changes to transfer energy; vane pump is to use the rotating blade and water interaction to transfer energy, there are centrifugal pumps, axial flow pumps and mixed flow pumps and other types.

- Q: Why is the submersible pump tripped on an electrical switch?There is no electrical leakage protection, directly connected to the circuit breaker, and when the switch on, the circuit breaker jumpedI checked the line is good, the pump did not break down, is not the water pump?

- Calculate or refer to the water pump nameplate that the normal operating current, according to this data exchange switch.2) with 500V shaking table, measuring the cable, motor insulation is in line with the requirements

Send your message to us

Horizontal, radially split volute casing pump CPKN

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches