Horizontal Multistage Centrifugal Boiler Feed Water Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Horizontal Multistage Centrifugal Boiler Feed Water Pump

1.Structure of Horizontal Multistage Centrifugal Boiler Feed Water Pump Description

Boiler Feed Centrifugal Multistage Water Pumpis used for transporting pure water (particles density shall be max.1%by volumeand granular size shall be max 0.1mm in dimeter) of the liquids with physical and chemical properties similar to pure water. Type MD pump is applied with wear resist material, especially suitable for mineral drainage. The particles density shall be max. 1.5% (Max. of the granular diameter is 0.5 mm).The liquid temperature ofD, MD pumps shall be lower than 80°C.

2.Main Features of the Horizontal Multistage Centrifugal Boiler Feed Water Pump

• Compact structure, good appearance, low construction

•Operation stably, same inlet and outlet

•Convenient installation and maintenance

•Customized design is available, OEM and ODM are welcomed.

•Horizontally and vertically installation as different pipeline system

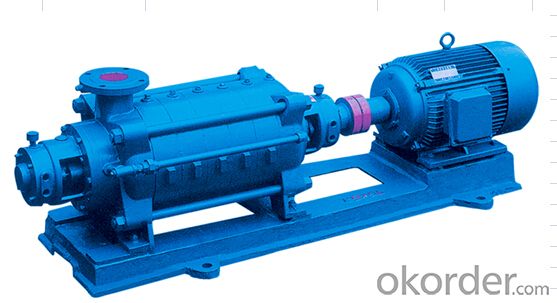

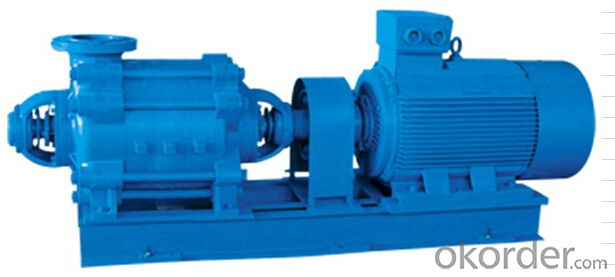

3. Horizontal Multistage Centrifugal Boiler Feed Water Pump images

4. Horizontal Multistage Centrifugal Boiler Feed Water Pump Specification

Item | Multistage Pump |

Multistage Pump | Horizontal Multistage Pump For Pure Water |

Model | CMD |

Material | Cast iron,Stainless steel |

Mode | Horizontal |

Color | Blue |

Temperature | <=80°c< span=""> |

Seal | packing seal |

Theory | Centrifugal Pump |

Structure | Multistage Pump |

Usage | Water |

Power | Electric |

Standard or Nonstandard | Standard |

Fuel | Diesel |

Pressure | High Pressure |

Application | Hot and cold pure water |

Outlet Diameter | 40-500mm |

Capacity | 6-1250 m3/h |

Head | 75-1800m |

Rotation Speed | 1450-2950r/min |

Power | 5.5-2400kW |

Certificate | ISO9001 |

Feature | High efficiency,Easy maintenance |

5.FAQ

① What is your product range?

Centrifugal pump, slurry pump, gravel pump, clean water pump, sewage pump, chemical pump, single stage

pump, double suction pump, industry pump, oil pump, paper pulp pump, mud pump, self-priming pump, pipe

water pump, boiler water pump, etc.

② Are you a manufacturer?

Yes, we have been in manufacturing and marketing industry centrifugal pump over 20 years.

③ What information should I let you know if I want to get a quotation?

Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please also

provide the pump model you are using now, price will be calculated as per the pump model, if not, we willrecommend relevant product for reference.

- Q: Shielding pump is the main drawback of electricity? How much does it cost more than an ordinary centrifugal pump? Is there any noise in the running of the canned pump? How much is it lower than the noise of the common centrifugal pump?

- The graphite bearing lubrication medium, make the operation less noise and manual, reduce maintenance costs; in recent years, bearing material added with silicon carbide SIC, super hard, life is better than that of graphite bearing.The vertical structure can be installed on the pipeline like a valve, the installation is convenient and quick, and the motor and the impeller can be drawn out only when the utility model is used, and the pipeline is not needed to be removed.The utility model can be installed and run with a shock absorber or a damping pad, so that the pump is less noisy at running time.

- Q: What is the pump delivery? What's the difference between years and years?

- 1) integer integer: ~ batch. Sell ~.2) buy in bulk: ~ goods. Sell now.The exchange is, according to the duration of the contract delivery insurance premium, payment is generally in common, 5 years of insurance you every year that time, continuous call five years; general single sex 5 years or even 10 years of premium.Furthermore, the insurance premium is good or good pay period, if a single rate from the point of view, to make cheaper than single period, but considering the one-time payment of the interest cost of funds and the opportunity cost, there is no difference. While the single cross ratio advantage is mainly reflected in its flexibility. First of all, additional premium may be added to the premium. At present, additional risks can only be covered if the main risks and principal risks are covered during the payment period. The single way to buy insurance, even in the primary insurance protection period will no longer be able to purchase additional insurance new; secondly, to pay the premium can enjoy a premium waiver. If the insured in full payment period has not yet had the danger, not pay part of the premium would be exempt from the Qing dynasty. For child insurance, the premium waiver is more advantageous. If parents unfortunate accidents or illness, resulting in death or one or two, three disabled or suffering from severe illness, the insurance company will be exempted after the premium, the insurance contract shall continue to be valid; finally, to pay the premium or additional premium amount can be changed. The policy holder may adjust his insurance plan according to the change in his economic strength. In contrast, single premium has the advantage of a one-time payment more convenient.

- Q: What is the function of the heating pump system for the water pump design?

- As the feed water temperature is higher, in the case of non warm pump start, will make the pump body is subject to greater thermal impact; in addition, the flow components with the pump contact heating fast, not contact with water directly heating slowly. This expansion due to uneven speed, it will inevitably produce thermal stress, deformation of the pump body, sealing surface, the joint surface is lax and leaking phenomenon. Therefore, the warm water pump system is designed for the water pump.

- Q: Is the sewage pump the same as the mud pump?

- Two of the main performance parameters of mud displacement and pressure, displacement from a number of liters per minute, with the diameter and the drilling fluid requirements from the hole on the back end of the speed, the larger aperture, the greater the displacement. The upstream return speed of the washing fluid is required to remove the cuttings and rock powder from the drill in a timely manner from the bottom of the hole and reliably carry it to the surface. Through drilling and extraction, mud can be obtained at the bottom.Sewage pump is mainly used for industrial wastewater treatment, sewage treatment, environmental protection has played a big role. Among them, the sewage pump is also a sewage pump with cutting wheel, such sewage pump can be chopped dirt, and then extract the sewage clean.

- Q: How high can the pneumatic diaphragm pump be?

- Pump made of polyvinylidene fluoride (PVDF) material two, the series of pneumatic diaphragm pump belongs to the fluorine plastic pneumatic diaphragm pump is also known as the corrosion products of pneumatic diaphragm pump, diaphragm liquid contact using PTFE material, using PVDF material produced by pneumatic diaphragm pump is mainly used in corrosive the pH, mainly used for chemical liquid conveying multiple solvent, corrosion resistance effect is very good. The series of fluorine plastic pneumatic diaphragm pump in high temperature less than 93.3 degrees.POM pump material also has good resistance to solvent and abrasion resistance, low friction resistance, moisture absorption is also low, the highest temperature of such pumps within 65.5 degreesPolytetrafluoroethylene (PTFE) membrane corrosion resistance is very good, in addition to liquid metal lithium, potassium fluoride, sodium fluoride, three chlorine, three fluoride high temperature oxygen, high flow rate, almost all of the chemical liquid transport (including concentrated nitric acid and aqua regia), PTFE material the maximum temperature to 176.6 degrees. However, for the diaphragm pump product as the diaphragm moves back and forth in work, we suggest that at a temperature of 120 degrees, the prerequisite is the pump body pump must be made of metal material and plastic material. The pump is the pump of PVDF material temperature is highest in less than 93.3 degrees.

- Q: Pump operator's responsibility 10Sharing the rules, responsibilities, etc..

- 3. master the operating rules of the pump operation, and make sure the pump position is reasonably determined. Do a good job of site investigation, find out, pay attention to.4. master the working principle and basic technical parameters of the delivery pump. Obey the command of production dispatcher to ensure the completion of production tasks.5., according to the number of tanker at the scene, determine the pumping speed, in order to ensure the continuity of pouring.6. normal pumping, the discharge rate should be uniform, to prevent uneven discharge, resulting in pressure pipe gas plug, and thus lead to pipe or pipe explosion accident.

- Q: Roots pump and dry pumpRecently involved in the work of the vacuum pump, don't understand this, is a ads602 vacuum pump, composed of roots pump and dry pump, is pre pumped to the 500mtorr equipment, the main pumping vacuum continues to 10mtorr, where the roots pump and dry pumps must be used? What role they play respectively. The so-called dry pump? Is refers to one kind of the pump, the pump is many dry pump? Also do not understand how the work of automatic switching system for pre pumping, the main pump, pump work alone did not connect system ah (of course there are even a butterfly) teach?

- The front stage pump to a certain pressure to start the roots pump, roots pump has advantages of is at the entrance of low pressure gas pumping speed is high, popular point is in high vacuum pumping speed is still relatively large. With the former pump can achieve different limit the vacuum is different.

- Q: What are the differences between the sewage pump and the clean water pump?

- The main difference between the sewage pump and the clean water pump is that:Impeller and runner design, as well as other parts of the configuration are very different.1., in order to prevent clogging of sewage pump, the main design of large flow channel, so naturally lead to relatively low efficiency, so the head is generally not high. Clear water pump flow smaller, smaller clearance, the head is relatively high.

- Q: What is the difference between an air pump and a water pump?

- The air pump (Q. B ng air pump), namely "air pump", a device for removing air or add air from the enclosed space from a closed space. The air pump is mainly divided into an electric air pump and a manual air pump. Electric air pump. An electric pump powered by electricity; produces air pressure by constantly compressing the air through electricity. Mainly used in pneumatic rubber, car inflatable, etc..

- Q: What are the failures and causes of the replacement of the fuel pump assembly?

- Gasoline pump is the gasoline from the gasoline tank suction and the gasoline tank has a certain pressure, thereby, it overcome the resistance of the pipeline, pipeline and fuel filter into the carburetor float chamber or electronically controlled injection engine in the guide frame.

Send your message to us

Horizontal Multistage Centrifugal Boiler Feed Water Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords