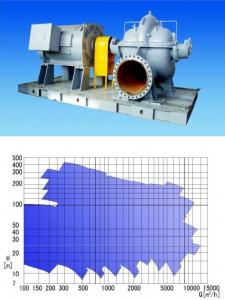

Horizontal Axially Split Casing Double Suction Pump SBS Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Advantage of SBS Horizontal Axially Split Casing Double Suction Pump

Easy mantainance

Higher efficiency&saving energy

Low noise

Non-leakage

Stabel runing and longer operation life

Exellent Performance

Compact Structure

Both horizontal and vertical installation

Easy installation the pipeline, suction and discharge in one line

Applications of SBS Horizontal Axially Split Casing Double Suction Pump

Type SBS Horizontal Axially Split Casing Double Suction Pump is wide apply in water works, irrigation, drainage pump station, power plant, municipal water supply system, firefighting, ship build. Also can be apply in oil process industry, drainage in civil building, HVAC, metallurgy, chemical, pharmacy, power plantetc for supply water or liquid property similar to water both in physics and chemical.

General description of SBS Horizontal Axially Split Casing Double Suction Pump

State Patents (Patent Number: ZL01 2 39077.1) the advantage of vertical& horizontal installation construction to fill domestic blank. To match different installation requirement. Strengthen casing design, high efficiency and save energy, compact design to ensure stable and reliable operation.

Model Explanation of SBS Horizontal Axially Split Casing Double Suction Pump

SBS 125 500F/412

SBS SBS Horizontal Axially Split Casing Double Suction Pump

125 - Discharge Diameter (mm)

500 Impeller Nominal Diameter (mm)

F - Impeller hydraulic Code

412- Impeller Diameter Code

Technical data of SBS Horizontal Axially Split Casing Double Suction Pump

Diameter of Discharge Flange: DN80 upto DN900

Capacity: Q: 83 - 11600m3/h

Head: H: 8 - 180m

Max Working Pressure: Cast iron 1.6MPa, Ductile Iron and Cast Steel 2.5MPa.

Max Operating Temperature: 120 degree

Rotation Direction: From the driven end, the pump rotating direction is CW, also CCW rotation direction is available if needed.

FAQ of SBS Horizontal Axially Split Casing Double Suction Pump

1. How can I get trained on CNBM products?

Yes, we provide training courses in our factory (products, general and specific pump technology, hydraulics, and practical applications). Please consult your sales manager or get in touch with our headquarters for more information.

2. Are your pumps cheaper than those of your competitors?

CNBM aims to give its customers the highest standards of quality and service and delivery times, all at a reasonable price.

3. Do you have self-priming pumps?

Yes, our product portfolio also includes two ranges of self-priming pumps: self-priming electric pumps and self-priming side channel pumps.

4. Is it really necessary to fit a bleed valve for the boxes?

It is always best to have a bleed valve as the gas produced by the fermenting sewage is potentially hazardous.

- Q: 7.63Determine the isentropic efficency of a water pump when water enters as a saturated liquid at 96.5 kPa and exits at 5 MPa and 106 degrees C.Thanks

- the only way a water pump can damage anything is if it locks up or quits working and the engine overheats and stops running. If your car has overheated enough and blew all the water out of the endgine and the head gasket went bad there may be water in your oil it would look milky like it had a milkshake in the oil. If your oil is ok and the coolant is not blowing out the tailpipe in big white clouds obscuring the cars behind you the engine may be ok as long as it has not blown steam for the last 20 minutes out the radiato Coolant may leak from the bottom of the water pump too if the water pump is bad. If the engine starts up and runds good in the morning and does not blow a bunch of steam at you it may be ok for awhile yet.r.

- Q: Would a bad water pump make a whinning sound when the engine is reved.....ive checked everything off as to why my car is running so hot and im down to the water pump.....ive put a New thermostat....no leaks anywhere.....no oil in coolant....no coolant in water.....no white smoke.....Fans do turn on.....new colant and i bleed the air out.....but the engine is still running really hot....my car calls for about 13 quarts of coolant but upon refil it took only about 4 quarts...... .. . uld this be signs of my water pump failing.....the pump is not leaking and when i took the housing off the water pump and turn the engine the blades did rotate...but at a higher rpm with the car together i heared weird noies kinda like a whinning sound from the water pump.....1995 Oldsmobile Aurora194,000Northstar 4.0 V8

- if you can wobble the pump shaft the pump is going bad but w/o leaking it really should leak first. get the engine to operating temp and from under the hood rev the motor at a steady speed to see if you have a hose sucking shut also check your rad pressure cap it just might not be releasing the pressure at the proper temp. good luck

- Q: An engineer is given the job of designing the water system for a tall building. He decides to locate the pumps at ground level and feed the entire building from there. If the top floor of the building is 236 m above ground level, what must the pressure be at pump level?

- Adding to Colin's answer, in addition to pgh, you also must add the atmospheric pressure, which is the pressure caused by the air at roughly the Earth's surface, unless whatever vessel the engineering is trying to pump the water into is a vacuum or otherwise not exposed to the air outside. atmospheric pressure: 1 atm = 1.013 x 10^5 Pa

- Q: I am trying to increase the pressure of my shower and I am looking to install a water pump. Does anyone know what kind of pump would work well for this? I don't want a big pressure pump, just a small one that will be cheap.

- American Standard has a shower head with a turbine in it. Get that. its made for low flow applications.

- Q: Two sewage pumps switch from each other, start with float switch control, the first sump, when the water is full, the first start, the second rotation to second units start, so the cycle of alternating

- Do you mean that 2 pumps are used in a hole? With float switch control, plus time relay 24 hours, every 12 hours at will, you set time, seconds, minutes can be

- Q: In my house. Any ideas regarding how much this is going to cost me?

- depends on where you live . as i've noticed in larger cities it cost more. also on the size of the water pump and heater. any ideas on the brand?

- Q: Multi storey residential buildings also need to set up pressurized water pump room, direct water supply can not be?

- Multi-storey residential building in general can use tap water pipe network pressure water directly, but all regions due to different network differences, in some areas, because of the lower pressure of the municipal pipe network, such as lack of high-rise building 5-6 pressure, can direct water supply cannot meet the demand of domestic water use, then you need the two pressurized water supply. The general water supply equipment needs the construction of pumping stations, and the pump house can be built on the first floor or the ground floor. There are also no water supply equipment, such as pipe pump, frequency conversion water supply equipment, the water supply equipment from outside to see, is a group of stainless steel pipeline, no pumping room. Outdoor box type water supply equipment is also a choice, water supply equipment comes with equipment, can be placed outdoors. Zibo Boshan new Duke water supply equipment

- Q: i already removed all bolts including the fan except for the last bolt on the water pump which the serpentine belt rides on the bolt backs into that so i am trying to find out how to get the bolt from the serpentine belt pulley off do i have to pull the serpentine pully off and if so how there is no bolt or allen holding the serpentine pully onim just trying to replace the water pump

- If the pulley is bolted from behind, the bracket has four bolts that mounts it to the block, you need to find those bolts remove the pulley/bracket assembly. If it is a 3800 engine you might need the plastic elbow from the bracket to the the intake manifold also. Coolant flows through that elbow to the heater hoses. poor design, I know but what are you gonna do? Got to love tose engineers LOL. Good luck

Send your message to us

Horizontal Axially Split Casing Double Suction Pump SBS Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords