HK 2214 Drawn Cup Needle Roller Bearings HK Series High Precision

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 900000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specifications:

Specification | Model No.: HK 2214 |

Brand Name: OEM | |

Size:22*28*14mm | |

Net weight: 0.017kg | |

Material: Chrome steel | |

Cage: Brass, Steel | |

Features: | 1) Precision: P6 P5 P4 P2 |

2) Noise level: Z1, Z2, Z3, Z4 | |

3) Vibration Level: V1, V2, V3, V4 | |

4) Clearance: C2, C3, C4 | |

5) Hardness: 58-63 HRC | |

6) Greese: As your requirement, such as SRL, PS2, Alvania R12 and so on. | |

Packing | 1.Industrial packing: box |

2.Commercial packing: box then into standard carton/wooden Box | |

3.According customer's requirement | |

Payment | T/T, L/C, Western Union |

Delivery time | About 3 to 5 working days |

Services | Warrantee: 1 year |

Samples: available | |

OEM: available | |

Free technical support and after-sales service |

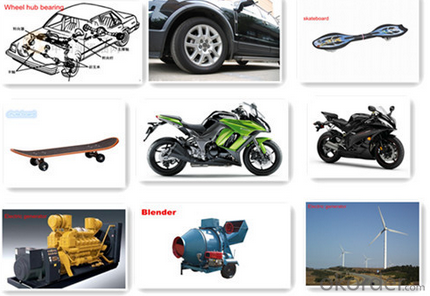

Product Applications:

Steel industry, oil industry,cement industry,mining&construction, papermaking machinery,rolling mill, sugar mill, vibrating screens, conveyors, air blower, transmissions, and other heavy machinery.

Needle roller bearings are mainly used in car engines, transmissions, compressors, cranes, etc.

Our Advantages:

1. Excellent and high quality control

2. Prompt delivery

3. Competitive price

4. Small order accepted

5. Customers' drawing or samples accepted

6. OEM service

Product Advantages:

1)Bearing Manufactory ( Have our own technical department)

2)High quality products (Long Life and low noise)

3)Well-daserved Reputation (Good Stock Guarantee)

4)Professional service ( Promptly shippment)

5)OEM Service,Sample is available

FAQ:

WHY CHOOSE US ???

1.More than 28 years export experience

2.Strict quality control

3.Delivery in time

4.OEM service are available with good price

5.Low MOQ

- Q: A friend of mine had his Nissan repaired recently. He had the timing chain and water pump replaced. A week later, the car dies. He returns to the shop that fixed it. They say his ball bearings are pretty much gone and that he needs a new engine. When he asked what could have caused this, they say that somewhere along the line a previous shop put the wrong trans fluid in his car and that that is the cause of this whole thing. Is this possible?

- Something is very wrong with this. The engine does not use ball bearings, but sleeve bearings that are lubricated by oil under pressure. Bearing failure makes a terrible racket and can soon lead to catastrophic engine failure - the engine dies with a horrendous bang, bang, bang, Bang! That shop is unwilling to give your friend an honest answer. He will have to take it someplace that can tell him why his engine quit. It is hard to avoid the suspicion the timing chain was installed wrong and the failure a week after the shop worked on it is the reason for the bogus explanation. Timing chain failure will definitely cause the engine to quit, and often does serious damage to the valves.

- Q: The Model is a Hustler. And it was bought around '76-'75. Would it take any kind of bearings or a certain kind? And where can I find a pair of trucks to fit?

- I okorder . The truck mounting holes probably are the old long mount configuration. Tracker six track trucks will work for the old as well as the new hole configuration.

- Q: 1973 buick centurion. posi rear.

- As stated above, check them while replacing the seals. A lot of the times, you can just repack them as long as they're in good condition.

- Q: I would like to ask about the difference between needle roller bearings NK and nki,Recently, I encountered a problem, originally wanted to buy NK 40/20 needle roller bearings. But it is later discovered that the label is NKI bearing 35/20 (inner) model, measure and NK 40/20 nominal size, only found nki35/20 needle roller bearings NK 40/20 bearing needle length is shorter a section, the other to look exactly the same.Considering the bearing equipment used in high precision, and the bearing capacity is large, so request, the use of NKI35/20 (inner) bearing replacement prototype No. NK 40/20, it has a bad effect on the accuracy of the equipment, whether this model can be used to replace.Therefore, I always have this doubt, hoping to get answers from professionals,.Thank you for putting it down hereWhat I want to ask is, if you take the NKI 35/20 inner ring off, can you take the place of NK40/20 bearing?If the NKI 35/20 bearing is installed, what impact will it have on the equipment?

- NK and NKI are light series needle roller bearings. The difference is that one with inner ring and one without inner ring. The following problems are shown. Relevant technical data of the model are compared. Are they in line with your requirements?:INA needle roller bearing NK40/20-TVLight seriesFw 40, mmD 50, mmC 20, mmRmin 0,3 mmM 78 g qualityCr 26000 N basic rated dynamic load radialC0r 47000 N basic rated static load radialCur 6700 N fatigue limit load, radialNG 10900 1/min limit speedNB 6400 1/min reference speedINA needle roller bearing NKI35/20-TVLight seriesD 35, mmD 50, mmB 20, mmF 40, mmRmin 0,3 mmS, 0,5, mm axial displacement distanceM 122 g qualityCr 33500 N basic rated dynamic load radialC0r 56000 N basic rated static load radialCur 9800 N fatigue limit load, radialNG 11500 1/min limit speedNB 6200 1/min reference speed

- Q: cylindrical roller bearings

- The rolling elements of the bearing are shaped like a cylinder.

- Q: what is the advantage and disadvantage of water-lubricated bearings?

- The main advantage of a water cooled bearing is you can use the a portion of the water from the pump discharge to lube the bearings. That way you can always be assured of the lubricating fluid supply and do not have to relay on another pump. Some pumps do use another source, especially if the water being pumped is dirty, but it is still cheap and non-contaminating if some leaks into the pumped fluid. However, water is not always a good lube especially on pumps with high speeds and/or mechanical loads. Water is not very viscous and becomes less so with increased temperature. Even small 3600 rpm pumps will use oil for lubrication. Some large, high pressure pumps will have their own oil pumping and cooling system for the bearings.

- Q: the lucky titanium bearings must not be 100% titanium because they will be too heavy, are they really 100% titanium or are they an alloy?

- Zenni Optical There are hundreds of 100% pure titanium eyeglasses at affordable prices.

- Q: does anybody know what the best liquid to use for cleaning bearings?

- I don't really know but i use rubbing alcohol. I would have alcohol in a cup and put my bearings in then with my top hand cover the top and shake a little. Then take em out and roll em until they feel like they're new again(sorry for bad english im mexican)

- Q: I am going to purchase some on amazon. What is the difference between the two? Please explain in detail.

- I thought you were talking about ball bearing hinges. I think I am incorrect though. If so electric ball bearing hinges are much more.

- Q: Back in the day(about 10 years ago) I had ceramic wheel, crank, water pump, countershaft, mainshaft and steering stem bearings. I was trying to find ceramic bearings for my son's KTM 50 and can't find anyone that sells them. I am trying to cut down on weight on his little bike. I am also trying to find a titanium shock spring for that little bike.Any help would be much appreciated. I have been trying Google for the past couple of days. This stuff is for the 50cc mod class not the stock class...

- Don't know how much help this would be to you as I have a crf250r and have ceramic bearings in it but being in Australia mine came from a company called Black Mamba Racing. They are worth the cost and it is a mod that most will not admit to but all the pros run them in their bikes. Finding them for a ktm 50 could be an issue though as most would not think to put them in therefore there may not be much of a market for it. So perhaps look for a company like Black Mamba that produce racing components in your country.

Send your message to us

HK 2214 Drawn Cup Needle Roller Bearings HK Series High Precision

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 900000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches