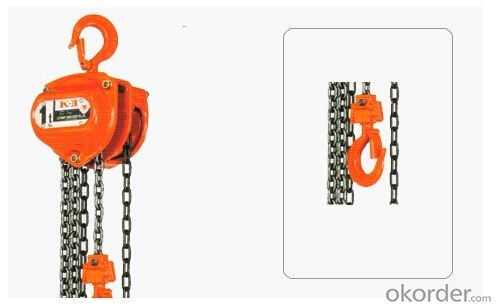

5t Explosion-Proof Chain Hoist high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 200 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Place of Origin: Hebei, China (Mainland)

Brand Name: CNBM

Model Number: HBSQ5T

Usage: Construction Hoist

Power Source: Hand Chain

Sling Type: Chain

Maximum Lifting Weight: 5 tons

Maximum Lifting Height: 3M

Lift Speed: same with pulling speed

Certification: CE,GS and ISO9001

Warranty: one year

After-sales Service Provided: No overseas service provided

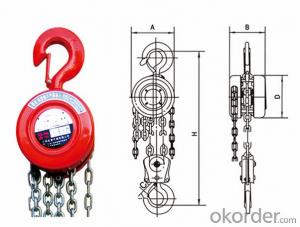

Capacity: 5 tons

Standard lift height: 3M

Running test load: 5TONS

No.of falls of load chain: 2

Net weigth: 65kg

Color: cooper color

Description: cooper chain hoist

Main Features

Superior rigidity makes the hoist dust-proof and water-pfoof;

Severe environment and work condition are acceptable;

Simple structure and few components

Adopt Janpanese FEC chain;

To greatly enhance the performance of the fatigue and wearresistance.

Limit protection adevice can avoid overload occerring;

Hook bolt can prevent the rigging accidently from slip;

Moter is equipped with thermal protection device;

limit contactors are set in the machine.

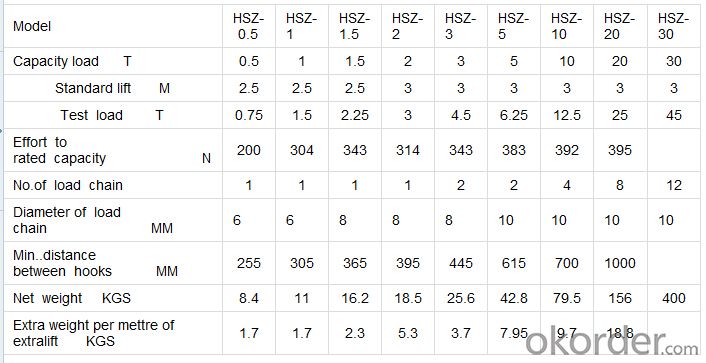

Parameter List

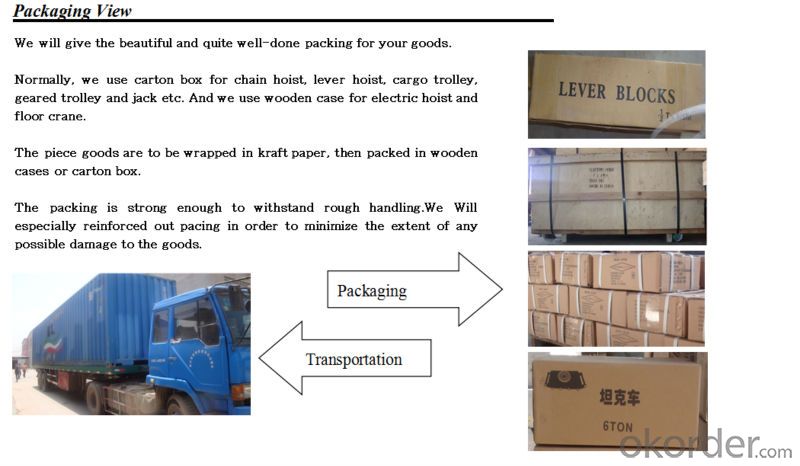

Our Service

1.We can make special sample according to the customer’s requirement.

2. We have more than 60 professional technical team, provide best after-sales service.

3. Fast delivery time.

4. We have CE, ISO9001 and GS certification.

FAQ

1.What’s your product range?

Electric Hoist: electric chain hoist , electric wire rope hoist, mini wire rope electric hoist, mini electric chain hoist.

Manual Chain Hoist and Lever Hoist Chain , Trolley , Jack,Lifting Strap,Cable Pulley, hand pallet truck,etc.

2.When Can I get the quotation?

We usually quote within 24 hours after we get your inquiry . If you are very urgent to get the price , please tell us in your email so that we will regard your inquiry priority.

3.How can I get a sample to check your quality?

After price confirmation, you can require for samples to check our quality. If you need the samples, you need pay the express fee ,

4.What information should I let you know if I want to get a quotation?

1. Lifting capacity.

2. Lifting height.(hook center to ground)

3. Power supply: Voltage.

4. Span(rail center to rail center)

5. Working condition: which material to lift? temprature?

6. Would be better if you have drawings of your plant.

- Q: What tools are slings in lifting operations? What is the function of the slings?

- A sling is also called a jack rope, a pair of rope or rope buckle. Hoisting works are more used, such as tying equipment, hanging blocks, stabilizing winches and so on. The utility model has the advantages of good quality and large elasticity, but the rigidity is large, and the bending is not easy, and once the bend is not easy to recover. Slings made of wire ropes of hemp core are not easy to work under high temperature.

- Q: What is the influence of lifting angle on rigging?

- Slings are usually steel wire ropes or chain slings. Wire ropes have manganese phosphating coating, steel wire rope, galvanized steel wire rope, manganese phosphating coating, steel wire rope is new technology product, and fatigue life is three times of smooth steel wire rope.

- Q: What is the line on the train for?

- The catenary provides 25 thousand volt power frequency alternating current for the locomotive, according to the locomotive model difference, adopts the direct step-down, the frequency conversion power supply or the AC and DC conversion power supply, this is mainly for the speed regulation convenience.

- Q: What are the dangerous sections of the crane hook?

- B -B and A-A section section of the same, B -B section in the sling tension loading, have been straightened and cut off the trend here, shearing stress is maximum, it is also dangerous section.

- Q: What is the name of the wire above the train?

- The catenary provides 25 thousand volt power frequency alternating current for the locomotive, according to the locomotive model difference, adopts the direct step-down, the frequency conversion power supply or the AC and DC conversion power supply, this is mainly for the speed regulation convenience.

- Q: What's the sling for a movie?

- WIA, is used to protect the athlete's device is generally with a strong rope tied to the athlete's protection belt.

- Q: What is the safety factor of the wire rope as a motor lifting equipment, slings and slings?

- 3. stainless steel wire rope, the use of stainless steel wire rope system, such as 304 or 316 stainless steel, the price is relatively expensive, the stainless steel wire for manganese phosphating coating (stainless steel wire need special phosphating phosphating formula), you can use the same life greatly extended.

- Q: How to choose the right sling?

- Commonly used slings and slings are lifting belts, lifting chains and wire ropes. Slings and slings must be matched with lifting equipment, such as 5 tons or 10 tons. Cranes shall be marked with maximum lifting weight. Lifting belt will not damage the hoisting object but poor wear resistance, easy maintenance but large weight lifting chain, rope buckle range but the broken wire after easily scratch objects and operators, each have advantages and disadvantages, to meet their own needs is the best lifting.Phosphating coating of steel wire rope production technology patent, give priority to the use of manganese or zinc manganese phosphating, and smooth steel wire rope production process comparison, just increase the steel wire wear phosphating process, phosphating of steel wire surface after the abrasion resistance and corrosion resistance is greatly improved, the use of direct phosphating steel wire twisting steel wire rope (steel wire after phosphating not drawing). The fatigue test data show that the fatigue life of the phosphating coating of steel wire rope is about 3-4 times the same structure of plain steel wire rope, wire rope is 2-3 times of imports (laboratory comparable conditions) with the research on the wear resistance of phosphating, and greatly enhance the possibility of. Manganese phosphating is wear resistant phosphating, which can completely solve the wear problem in the use of wire rope.

- Q: Which sling manufacturer is more reliable?

- Rigging is made of wire rope, plug or aluminium alloy head, and the key to the service life of the rigging is the quality of the wire rope.

- Q: Notice of tower crane?

- Tower cranes shall not operate near overhead transmission lines. If they are limited to field conditions, they must take safety measures when operating alongside the line. The safe distance between tower crane and overhead transmission line shall comply with the regulation.

Send your message to us

5t Explosion-Proof Chain Hoist high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 200 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords