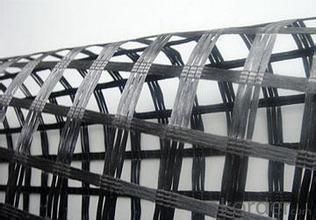

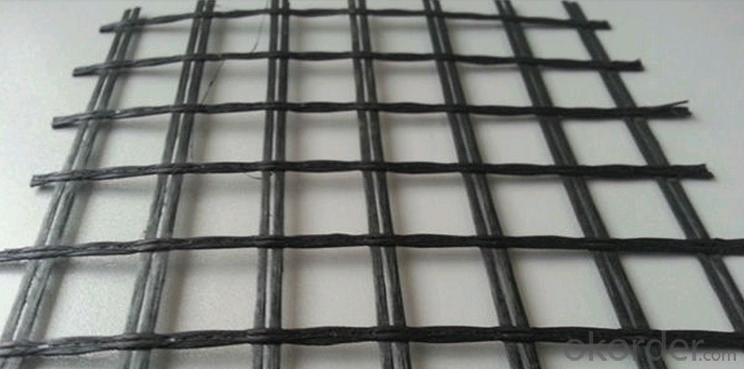

High Tensile Strength Fiberglass Geogrids and Geomembranes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid with CE Certificate,Welcome choose us!

Product Description

Bitumen coated fiberglass geogrid

Fiberglass geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed. This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile strength, low unit extension, high flexibility, and favorable high and low temperature resistance. The products after surface covering own the favorable property of alkali resistance and aging resistance.

| Property of Fiberglass Geogrid |

| Property | Test Method | TGSB | TGSB | TGSB | TGSB | TGSB | TGSB | TGSB | |

| 30-30 | 40-40 | 50-50 | 60-60 | 70-70 | 80-80 | 90-90 | |||

| Ultimate tensile strength(1) (kN/m) | MD | EN ISO 10139 | 30 | 40 | 50 | 60 | 70 | 80 | 90 |

| CD | 30 | 40 | 50 | 60 | 70 | 80 | 90 | ||

| Elongation at maximum load (%) | MD | 3 | |||||||

| CD | 3 | ||||||||

| Approximate mesh size(mm) | 12.7mm×12.7mm 25.4mm×25.4mm 40mm×40mm | ||||||||

| Roll Width (m) | 1m-6m | ||||||||

| Roll Length(m) | 50m-200m | ||||||||

| Property | Test Method | TGSB | TGSB | TGSB | TGSB | TGSB | TGSB | TGSB | TGSB | |

| 100-100 | 120-120 | 130-130 | 150-150 | 160-160 | 170-170 | 180-180 | 200-200 | |||

| Ultimate tensile strength(1) (kN/m) | MD | EN ISO 10139 | 100 | 120 | 130 | 150 | 160 | 170 | 180 | 200 |

| CD | 100 | 120 | 130 | 150 | 160 | 170 | 180 | 200 | ||

| Elongation at maximum load (%) | MD | 3 | ||||||||

| CD | 3 | |||||||||

| Approximate mesh size(mm) | 12.7mm×12.7mm 25.4mm×25.4mm 40mm×40mm | |||||||||

| Roll Width (m) | 1m-6m | |||||||||

| Roll Length(m) | 50m-200m | |||||||||

Packaging & Delivery

| Packaging Details: | plastic pipe + black PE membrane |

| Delivery Detail: | one 40HQ within 15 days after receipt of T/T or L/C at sight |

FAQ

1. How about the delivery time?

Lead time since receipt of 30% T/T deposit payment: 3 weeks.

2. What kind of payments does jenor support?

T/T, L/C, Cash are accepted.

3. What's are the MOQ?

We can according to your condition to set the MOQ.

And we can provide you samples for quality inspection.

4. Do you charge for the samples?

Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee If you set the order .

5. Can you produce the product according to customers' requirements ?

Sure, we are professional manufacturer, OEM and ODM are both welcome.

6. Can you tell me your main customers?

That's our customers' privacy, we should protect their information. At the same time, please rest assured that your information is also safe here.

- Q: Which floor is paved on the roadbed

- Glass fiber geogrid is generally laid under the asphalt, soft foundation treatment of the geogrid as the design of the water layer in the layers of laying

- Q: What is the effect of installation damage on geogrid behavior?

- The effect of installation damage on geogrid behavior can vary depending on the extent and severity of the damage. In general, installation damage can compromise the structural integrity of the geogrid, reducing its tensile strength and overall performance. It can lead to premature failure, decreased load-bearing capacity, and increased deformation or displacement. Therefore, proper installation techniques and precautions should be followed to minimize installation damage and ensure optimal geogrid performance.

- Q: How do geogrids improve the performance of flexible bridge abutments?

- Geogrids improve the performance of flexible bridge abutments by providing reinforcement and stabilization to the soil. They increase the load-bearing capacity of the abutment, prevent soil erosion, and enhance overall structural integrity.

- Q: Are geogrids resistant to corrosion?

- Yes, geogrids are generally resistant to corrosion. They are commonly made from materials such as high-density polyethylene (HDPE) or polyester, which are not prone to corrosion. This makes geogrids suitable for various applications in civil engineering and construction, where they may be exposed to moisture, chemicals, or other corrosive elements.

- Q: Are geogrids suitable for reinforcing contaminated soil?

- Yes, geogrids are suitable for reinforcing contaminated soil. Geogrids are commonly used in soil reinforcement applications due to their high tensile strength and ability to distribute loads. They can effectively stabilize and reinforce soil, even when it is contaminated. Geogrids provide additional support to prevent soil movement and erosion, making them a viable option for reinforcing contaminated soil.

- Q: Geogrid what to do

- Test items include: strength, elongation at break, amount of glue, weight, mainly to measure the strength of the grid.

- Q: Can geogrids be used in bridge abutment construction?

- Yes, geogrids can be used in bridge abutment construction. Geogrids are often used as reinforcement materials in soil structures, including bridge abutments, to improve the stability and strength of the soil. They can help distribute loads and reduce settlement, making them a valuable addition to bridge abutment construction projects.

- Q: How do geogrids improve the load-bearing capacity of soils?

- Geogrids improve the load-bearing capacity of soils by providing reinforcement and stabilizing the soil matrix. When geogrids are installed within a soil mass, they create a strong interlocking system, distributing the applied loads more evenly and reducing the potential for soil movement or settlement. This reinforcement effectively increases the soil's shear strength and overall stability, enabling it to withstand higher loads and improve its load-bearing capacity.

- Q: How do geogrids improve the performance of geosynthetic-reinforced slopes in liquefaction-prone areas?

- Geogrids improve the performance of geosynthetic-reinforced slopes in liquefaction-prone areas by providing additional strength and stability. These synthetic materials are used to reinforce the soil and prevent it from shifting or sliding during liquefaction events. The geogrids act as a reinforcement layer within the soil, increasing its shear strength and reducing the potential for slope failure. Additionally, geogrids help to distribute loads more evenly across the slope, reducing stress concentrations and improving overall slope stability in liquefaction-prone areas.

- Q: Can geogrids be used in foundation stabilization?

- Yes, geogrids can be used in foundation stabilization. They are commonly used in civil engineering and construction projects to reinforce soil and improve the stability of foundations. Geogrids are typically installed horizontally or vertically within the soil to distribute loads and prevent soil movement, thereby enhancing the overall stability and performance of foundations.

Send your message to us

High Tensile Strength Fiberglass Geogrids and Geomembranes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords