High Tensile Strength Polyester Geogrids and Geomembranes

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

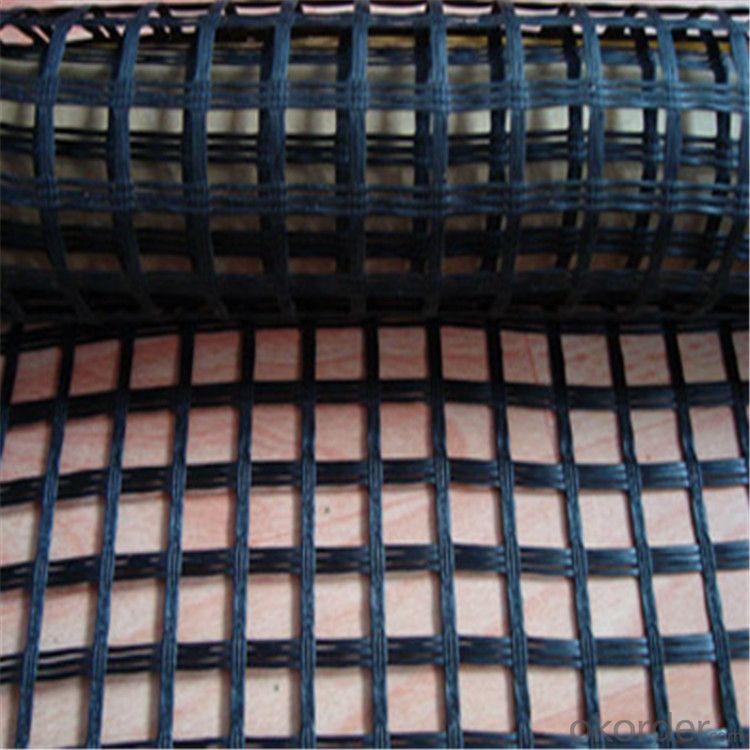

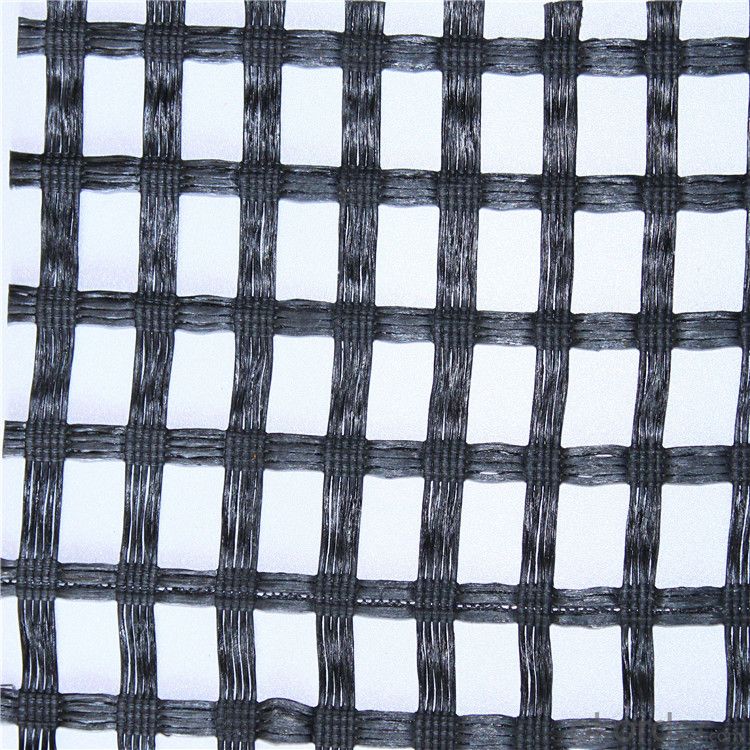

Product Specification---Polyester Geogrid

Introduction:

Polyester geogrid is a new kind of favorable earthwork base material to strength the road surface and roadbed, which composed of high strength polyester yarns coated with an inorganic sizing agent.

Features:

1) High tensile strength

2) High tear-resistant

3) Strong combination with gravel and soil

Specifications :

Mesh size(mm) | 25.4×25.4 Or 12.5×12.5 | |||||

Breaking strength ≥(KN/m) | Warp direction | 30 | 50 | 80 | 100 | 120 |

Across warp | 30 | 50 | 80 | 100 | 120 | |

Elongation at break ≤(%) | Warp direction | 3 | ||||

Across warp | 3 | |||||

Elasticity modulus(GPA) | 67 | |||||

Thermal tolerance | -100~280℃ | |||||

Width | 1~6m | |||||

Application:

This product is used to strengthen the soft land, such as railway, airport, irrigation work, and dyke, roadbed, and softland loading capacity strengthen.

Function:

This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile

strength, low unit extension, high flexibility, and favorable high and low temperature resistance. The products after

surface covering own the favorable property of alkali resistance and aging resistance.

It is used widely to increase the asphalt road surface, concrete road and roadbed (both soft and hard road surfaces).

Compared with the traditional road surface, it reduces the cost, prolong the service life, and avoid the reflection road

crackle.

This product is also used to strengthen the soft land, such as railway, airport, irrigation work, and dyke, etc, and the

roadbed 。

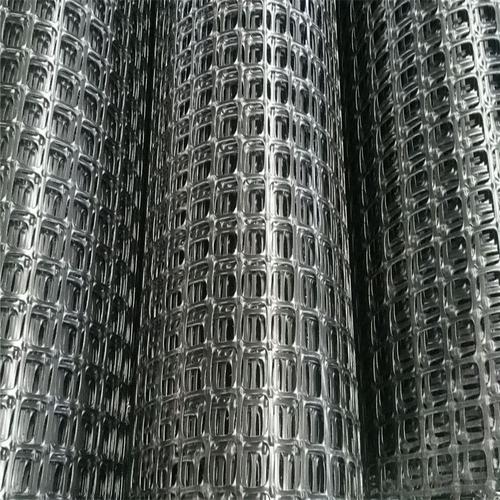

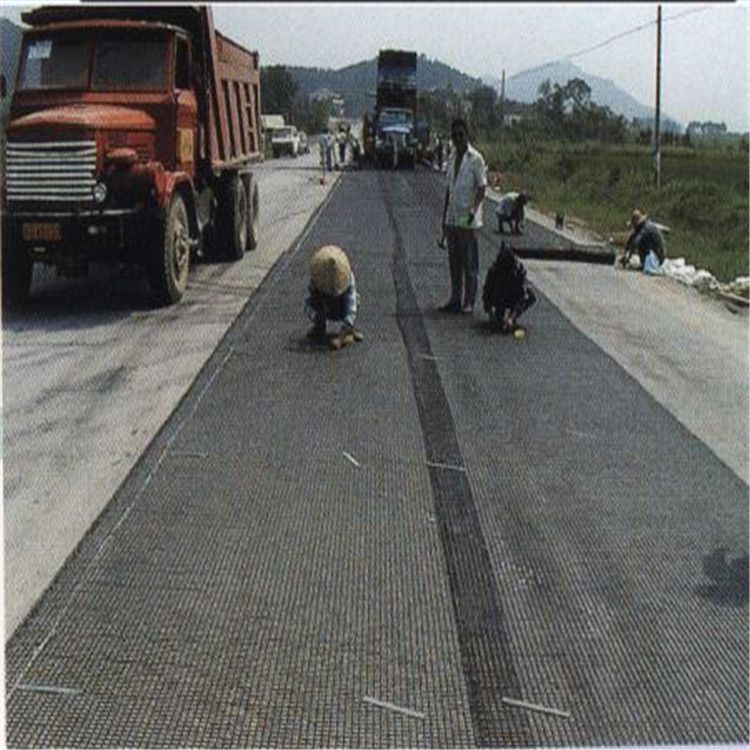

Image of Polyester Geogrid

- Q: Can geogrids be used in stabilization of mine tailings ponds?

- Yes, geogrids can be used in the stabilization of mine tailings ponds. Geogrids are commonly used in civil engineering for soil stabilization and reinforcement. They can provide strength and stability to the soil, preventing erosion and minimizing the risk of slope failure. In the context of mine tailings ponds, where the soil is often unstable and prone to erosion, geogrids can be an effective solution for stabilizing the area and preventing environmental hazards.

- Q: Can geogrids be used in soil reinforcement for oil and gas pipeline projects?

- Yes, geogrids can be used in soil reinforcement for oil and gas pipeline projects. Geogrids are commonly used to improve the stability and load-bearing capacity of soil, making them suitable for reinforcing the soil around pipelines. They help to prevent soil erosion, increase the overall strength of the soil, and provide support to the pipelines, ensuring their safe operation.

- Q: Are geogrids compatible with different soil types?

- Yes, geogrids are generally compatible with different soil types. Geogrids are versatile materials that can be used with various soil types, including clay, sand, and gravel. They are designed to provide reinforcement and stability to the soil, improving its load-bearing capacity and preventing erosion. However, the specific type and design of the geogrid may vary depending on the soil characteristics and engineering requirements of the project.

- Q: Are geogrids suitable for reinforcing landfill caps?

- Yes, geogrids are suitable for reinforcing landfill caps. They are often used in landfill engineering to enhance the stability and integrity of landfill covers. Geogrids provide reinforcement by distributing loads and reducing stress concentrations, thereby preventing soil erosion and controlling deformation in the cap system. Additionally, geogrids can improve the long-term performance of landfill caps by increasing their resistance to settlement and enhancing their overall structural integrity.

- Q: Performance parameters of steel plastic geogrid

- After 100 freeze-thaw cycles per meter elongation% mesh net from mm antifireeze Index C viscosity, peel strength of N solder joint ultimate longitudinal and transverse longitudinal and transverse longitudinal and transverse longitudinal and transverse longitudinal and transverse

- Q: Can geogrids be used for slope stabilization?

- Yes, geogrids can be used for slope stabilization. Geogrids are commonly used in civil engineering to reinforce and stabilize slopes by providing tensile strength and improving the overall stability of the soil. They are effective in preventing soil erosion, reducing the risk of landslides, and ensuring the long-term stability of slopes.

- Q: How do geogrids help in reducing construction waste?

- Geogrids help in reducing construction waste by providing a stable base for construction materials, reducing the need for excessive excavation and fill. This minimizes the amount of waste generated during the construction process and saves resources by utilizing existing materials efficiently. Additionally, geogrids enhance the durability of structures, reducing the need for frequent repairs or replacements, which further reduces construction waste.

- Q: Can geogrids be used in reinforcement of underground storage facilities for hazardous materials?

- Yes, geogrids can be used in the reinforcement of underground storage facilities for hazardous materials. Geogrids are highly effective in providing soil reinforcement and stabilization, which is crucial for ensuring the structural integrity and safety of underground storage facilities. By enhancing the load-bearing capacity of the surrounding soil, geogrids can help prevent ground movements and potential leaks or ruptures, thereby minimizing the risks associated with storing hazardous materials.

- Q: What are the design guidelines for geogrid-reinforced retaining walls?

- The design guidelines for geogrid-reinforced retaining walls include factors such as the type and strength of the geogrid, wall height, soil properties, and loading conditions. The design should ensure proper connection between the geogrid and the wall structure, adequate embedment of the geogrid in the soil, and appropriate spacing and orientation of the geogrid layers. Additionally, the guidelines may cover construction techniques, stability analysis, and considerations for drainage and backfill materials.

- Q: Can geogrids be used in reinforcement of underground tunnels and caverns?

- Yes, geogrids can be used in the reinforcement of underground tunnels and caverns. Geogrids are high-strength materials that can provide stability and support to the surrounding soil or rock mass in underground structures. They can be used to reinforce the tunnel walls, prevent ground movement, and increase the overall strength of the tunnel structure. Geogrids are commonly used in geotechnical engineering projects to enhance the stability and longevity of underground tunnels and caverns.

Send your message to us

High Tensile Strength Polyester Geogrids and Geomembranes

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords