High Tensile Strength Fibreglass Geogrids Suitable for Different Countries

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

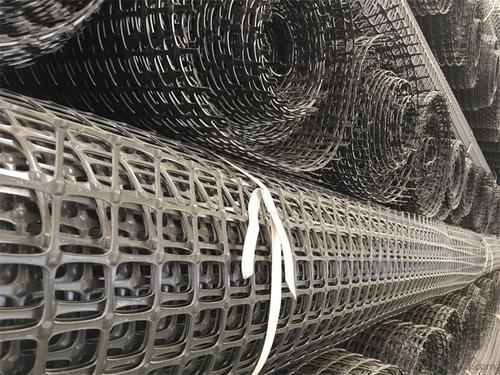

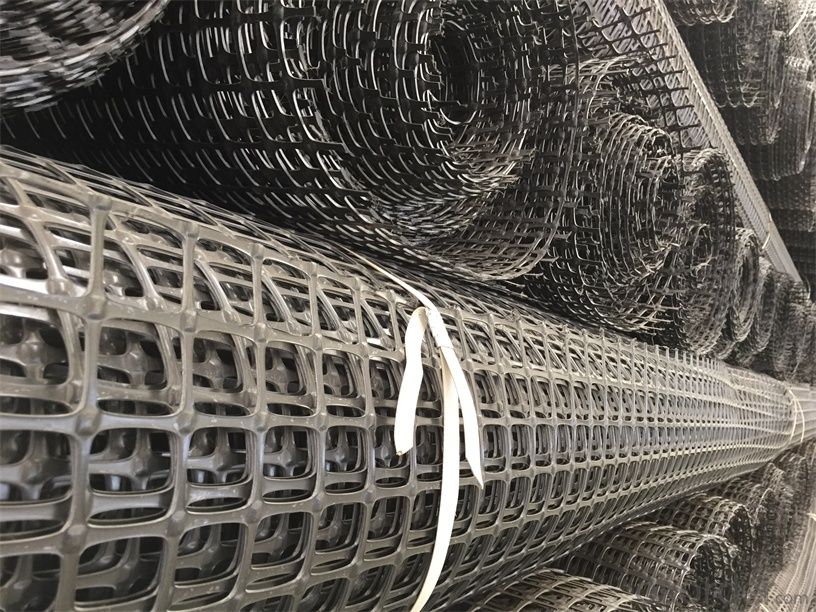

Uniaxial Geogrid with High Tensile Strength Suitable for Different Country Introduction:

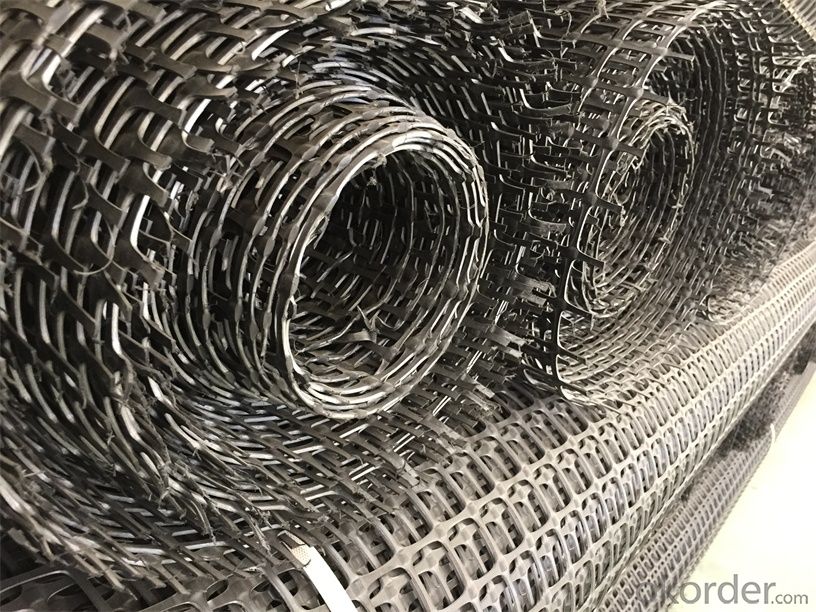

Fiberglass geogrid is a kind of planar mesh material using alkali-free fiberglass yarn as base body and then coated with high quality modified asphalt. It is warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant. Moreover, the composite property of coating with asphalt makes full protection of the fiberglass matrix and greatly improves its wear and shear resistance. All the advantageous functions make the product have a good performance in pavement strengthening, track cracking and solving difficulties of strengthening the bituminous pavement.

Uniaxial Geogrid with High Tensile Strength Suitable for Different Country Features:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Specifications | PET20-20 | PET30-30 | PET40-40 | PET50-50 | PET80-80 | PET100-100 | PET120-120 |

Elongation(%) | 10%~15% | ||||||

Vert Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Horiz Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Grid(mm) | 12.5×12.5 20×20 24.5×24.5 | ||||||

Width(m) | 1—6 | ||||||

Uniaxial Geogrid with High Tensile Strength Suitable for Different Country Application:

1. Road surface asphalt overlay construction engineering; Asphalt layers

reinforcement.

2. Converting old cement concrete road into composite road; Restraining

reflection cracking caused by block shrinkage.

3. Road extension; Preventing and controlling the cracking caused by new

and old combination and uneven settlement.

4. Treatment of the conjunction between tunnel and bridge or foundation.

Uniaxial Geogrid with High Tensile Strength Suitable for Different Country Packaging & Shipping:

FAQ:

1. How to order your geogrid ?

a) Tensile strength in warp & weft direction

b) Grid size

c) Roll Width and length

d) Quantity

2. What is the Payment term?

a) TT

b) LC AT SIGHT

c) cash

d) 30% contact value as deposit ,the blance 70% be paid after received the copy of bl .

3. Delivery time

a) 19-25 days after received your depsit .

4. What is MQQ ?

a) 2500 m2 as MQQ , we can also produce sample for you .

Welcome to send your inquiry to us, and if you have any question, we can also help you.

- Q: Can geogrids be used in soil stabilization for sports fields?

- Yes, geogrids can be used in soil stabilization for sports fields. Geogrids are commonly used to reinforce soil, increase its strength and stability, and prevent erosion. They can help distribute loads and minimize soil movement, making them suitable for sports fields that experience heavy foot traffic and require a stable playing surface.

- Q: What are the factors that affect the long-term creep behavior of geogrids?

- The factors that affect the long-term creep behavior of geogrids include the type and quality of the geogrid material, the magnitude and duration of the applied load, the temperature and moisture conditions, the stiffness of the surrounding soil, and the installation and construction techniques.

- Q: How do geogrids improve the performance of geotextile erosion control blankets?

- Geogrids improve the performance of geotextile erosion control blankets by providing additional reinforcement and stability to the blanket. They help distribute loads more evenly, prevent soil erosion, and enhance the overall strength and durability of the erosion control system.

- Q: Is it possible to add fiberglass grille between asphalt pavement and asphalt pavement

- First look at the drawing design requirements

- Q: Are geogrids effective in stabilizing embankments for pipeline crossings?

- Yes, geogrids are effective in stabilizing embankments for pipeline crossings. Geogrids provide reinforcement and enhance the stability of the soil, preventing erosion and minimizing settlement. They distribute loads efficiently, increasing the overall strength of the embankment and ensuring long-term stability for pipeline crossings.

- Q: GDZ150 type one-way steel plastic welding geogrid D in the construction of the roadbed is horizontal paving also vertical spread?

- Of course it is perpendicular to the direction of the route

- Q: How do geogrids enhance the performance of geosynthetic clay liner capillary barriers?

- Geogrids enhance the performance of geosynthetic clay liner capillary barriers by providing additional reinforcement and stability to the liner system. They help to distribute and reduce the load on the clay liner, preventing its deformation and maintaining its integrity. The geogrids also improve the shear strength and tensile properties of the clay liner, enhancing its ability to resist cracking and maintain its barrier function against water or other fluids. Overall, the presence of geogrids enhances the long-term performance and durability of geosynthetic clay liner capillary barriers.

- Q: How do geogrids improve the stability of embankments and slopes?

- Geogrids improve the stability of embankments and slopes by providing reinforcement and soil confinement. They act as a structural support system, distributing the tensile forces throughout the geogrid material and preventing the soil from sliding or eroding. This reinforcement reduces the risk of slope failures and enhances the overall stability of the embankment, making it capable of withstanding larger loads and improving long-term performance.

- Q: How much is the overlap length of Geogrid

- The horizontal distribution of shear walls should be staggered staggered 500mm, lap length 1.2LaE.

- Q: How do geogrids prevent differential settlement?

- Geogrids prevent differential settlement by distributing and reinforcing the load across a wider area, providing stability and preventing the shifting or settlement of soil.

Send your message to us

High Tensile Strength Fibreglass Geogrids Suitable for Different Countries

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords