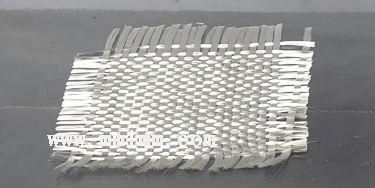

Fiberglass Laminated Scrims Mesh Fabric - Hisilica Fiber Cloth 2024

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Place of Origin: | Brand Name: | Model Number: | |||

| Weight: | Width: | Yarn Type: | |||

| Alkali Content: | Standing Temperature: | Weave: | |||

| Available treatmetn: |

Packaging & Delivery

| Packaging Detail: | Cartons |

| Delivery Detail: | 15-20days |

Specifications

Working temp.:2000F(1100C)

Width: 910mm

Thickness:0.65/1.2/1.35mm

Application:Heat preservation,firefighting,filtration

- Q: How does fiberglass fabric perform in insulation against sound?

- Fiberglass fabric performs exceptionally well in insulation against sound. Due to its dense and fibrous composition, it effectively absorbs sound waves, reducing noise transmission and providing a quieter environment. Its high acoustic insulation properties make it a popular choice for soundproofing applications in various industries.

- Q: How is fiberglass fabric measured and sold?

- Fiberglass fabric is typically measured and sold by weight per square yard or meter. It is commonly available in rolls or sheets of various widths and lengths to accommodate different project requirements.

- Q: How is fiberglass fabric used in the manufacturing of sports equipment?

- Fiberglass fabric is commonly used in the manufacturing of sports equipment due to its lightweight and high-strength properties. It is often used as a reinforcement material in the construction of various sports equipment such as surfboards, skis, hockey sticks, and kayaks. The fabric is typically combined with resin and molded into the desired shape, providing enhanced strength, durability, and flexibility to the final product.

- Q: Can fiberglass fabric be used for insulation in pipelines?

- Yes, fiberglass fabric can be used for insulation in pipelines. Fiberglass fabric is known for its excellent thermal insulation properties and is commonly used in various industrial applications, including pipeline insulation. It is an effective material for reducing heat loss or gain in pipelines and helps maintain the desired temperature of the transported fluid. Fiberglass fabric is lightweight, flexible, and easy to install, making it an ideal choice for insulating pipelines. Additionally, it is resistant to corrosion, moisture, and chemical exposure, ensuring long-term insulation performance.

- Q: How does fiberglass fabric perform in impact resistance?

- Known for its exceptional impact resistance properties, fiberglass fabric utilizes interwoven glass fibers in its composition to efficiently absorb and distribute impact energy. This quality enables it to withstand damage caused by impacts or collisions, as the inherent strength and rigidity of the glass fibers create a robust barrier against external forces, preventing cracks, fractures, or breakage. Moreover, the fabric's flexibility enables it to conform to various shapes, further bolstering its ability to resist impacts. Consequently, fiberglass fabric proves ideal for industries such as automotive, aerospace, and construction that necessitate protection against impacts.

- Q: How is fiberglass fabric used in the production of sports helmets?

- Due to its unique properties, fiberglass fabric is widely used in the manufacturing of sports helmets. Its strength and durability are well-known, providing excellent impact resistance to protect the head during sports activities that involve collisions and falls. The production process involves several steps. To achieve the desired helmet shape, the fiberglass fabric is layered and molded using a combination of heat and pressure. This allows the fabric to conform precisely to the specific contours and curves required for a comfortable and secure fit. In addition, fiberglass fabric is lightweight, making it an excellent choice for sports helmets. It does not add unnecessary weight to the user's head, ensuring comfort and reducing fatigue during extended use. Its lightweight nature also allows for greater maneuverability and agility, which is especially important in fast-paced sports. Another significant advantage of fiberglass fabric in sports helmets is its resistance to water and moisture. This ensures that the helmet remains intact and functional even in wet conditions, such as during water sports or heavy sweating. Moreover, fiberglass fabric is resistant to UV radiation, preventing degradation and maintaining the helmet's structural integrity over time. Lastly, fiberglass fabric offers customization and design flexibility. It can be easily combined with other materials or coatings to enhance specific features of the helmet, such as adding an extra layer of protection or improving its aerodynamics. In conclusion, fiberglass fabric is an essential component in the production of sports helmets due to its strength, durability, lightweight nature, resistance to water and UV radiation, and design flexibility. It plays a crucial role in ensuring the safety and comfort of athletes participating in various sports activities.

- Q: Is fiberglass fabric suitable for use in architectural membranes?

- Yes, fiberglass fabric is suitable for use in architectural membranes. It offers several advantages such as high strength, durability, and fire resistance. Additionally, fiberglass fabric can be lightweight and flexible, making it ideal for creating unique and innovative architectural designs.

- Q: Difference between glass fiber felt and glass fiber cloth

- According to the thickness of warp and weft lines, the density of warp and weft, as well as the materials at the later stage, are divided into many branches. Glass fiber mesh is one of them.

- Q: Can fiberglass fabric be used for insulation sheets?

- Yes, fiberglass fabric can be used for insulation sheets. Fiberglass fabric is widely used in insulation applications because of its excellent thermal properties. It is a non-combustible material that can withstand high temperatures, making it ideal for insulating various areas such as walls, roofs, pipes, and ducts. Fiberglass fabric is also resistant to moisture, which helps prevent the growth of mold and mildew. Additionally, it is a highly durable material that can effectively trap heat or cold, providing efficient insulation for both residential and commercial buildings.

- Q: What are the different widths available for fiberglass fabric rolls?

- Different applications and preferences are accommodated by various widths of fiberglass fabric rolls. The manufacturer determines the available widths, which can differ, but some common choices are 1 inch, 2 inches, 3 inches, 4 inches, 6 inches, 12 inches, and 24 inches. These widths are intended to provide flexibility and versatility for a wide range of projects, ranging from minor repairs and patching to more extensive undertakings like boat construction or automotive repairs. To ascertain the precise widths offered for fiberglass fabric rolls, it is imperative to consult the particular supplier or manufacturer, as they may provide additional or customized choices to suit specific requirements.

Send your message to us

Fiberglass Laminated Scrims Mesh Fabric - Hisilica Fiber Cloth 2024

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords