High Temperature Graphite Coated Fiberglass Fabric Heat Resistant Glass Cloth with Ptfe Coating

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

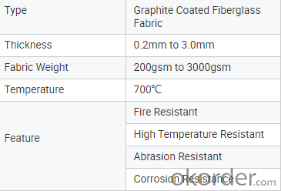

Description: Graphite coated fiberglass Fabric is a unique cloth constructed from base material of fiberglass fabric impregnated with graphite on both sides to increase the temperature resistance capability of the finished product. The coating also improve the performance where flexing is involved. Graphite coated glass cloth is high temperature & corrosion resistant. It also has excellent heat resistance, good abrasion and release properties.

Features: High Temperature And Heat Resistance, Good Abrasion

Application: welding defender, welding blanket ,fire blanket, fire curtain, high temperature, foundry splash protection, heat protection quilts, heat shields, sleeves, connectors and insulation jackets

PRICE: USD7 per square meter

UNIT: square meter

MOQ: 500square meters

Weight: 200gsm-3000gsm or customized

Width: 1m-2m or customized

Yarn Type: E-glass

Standing temperature: 700℃

Product name: Graphite coated fiberglass fabric

Coating/Finish/Surface Treatment: Graphite coated

Roll length: 50 meter or customized

Color: Black

Weave Type: plain woven

Alkali content: Alkali free

Processing service: cutting

Material: fiberglass fabric, Graphite

Thickness: 0.2mm to 3mm

Size: can be customized

Supply ability: 300000 meters per month

Packaging: Graphite coated glass cloth rolls packed in cartons loaded on pallets or according to customers' requirements.

Lead time: 7-30 days

- Q: Is fiberglass fabric resistant to tearing or ripping?

- Yes, fiberglass fabric is highly resistant to tearing or ripping. Fiberglass is a strong and durable material that is often used in applications where tear resistance is important, such as in the manufacturing of protective clothing, industrial curtains, or reinforcements for composite materials. The tightly woven structure of fiberglass fabric makes it difficult for tears or rips to propagate. Additionally, fiberglass is known for its excellent tensile strength, which further enhances its resistance to tearing.

- Q: Can fiberglass fabric be used for insulation in chimneys and flues?

- No, fiberglass fabric should not be used for insulation in chimneys and flues. It is not designed to withstand the high temperatures and corrosive gases present in these environments. Specialized insulation materials, such as refractory insulation or ceramic fiber blankets, should be used instead to ensure proper safety and performance.

- Q: How does fiberglass fabric perform in high-temperature environments?

- Fiberglass fabric performs well in high-temperature environments due to its excellent heat resistance properties. It can withstand temperatures up to 1000°F (540°C) without significantly degrading or melting. This makes it a suitable material for various applications such as insulation, fireproofing, and protective clothing in industries where high temperatures are present.

- Q: Is fiberglass fabric suitable for making protective covers for machinery?

- Yes, fiberglass fabric is suitable for making protective covers for machinery. It is a durable and strong material that offers excellent resistance to heat, chemicals, and abrasion. Additionally, fiberglass fabric is lightweight, flexible, and can be easily molded to fit various shapes and sizes, making it an ideal choice for protective covers that need to provide reliable protection against potential hazards.

- Q: How is fiberglass fabric printed?

- Depending on the desired outcome and project requirements, fiberglass fabric can be printed using a variety of techniques. One commonly used method is screen printing, where ink is transferred onto the fabric through a mesh screen, allowing for precise and detailed designs. Another technique is digital printing, which involves specialized printers directly applying ink onto the fiberglass fabric. This method offers flexibility in terms of design complexity and color choices, resulting in high-quality and vibrant prints. Additionally, heat transfer printing can be employed on fiberglass fabric. This process uses heat to transfer a design from special paper onto the fabric, activating the ink and bonding it with the fabric fibers. The result is a durable and long-lasting print. It's important to consider that the specific printing method may vary depending on the type and thickness of the fiberglass fabric, as well as the intended use. Therefore, it is advisable to seek professional advice or consult with the manufacturer to determine the most appropriate printing technique for a specific project.

- Q: Can fiberglass fabric be used for electrical cables?

- Yes, fiberglass fabric can be used for electrical cables. Fiberglass fabric is known for its high electrical insulation properties, making it suitable for applications where electrical conductivity needs to be minimized. It can be used as an outer layer or insulation in electrical cables to protect against electrical shocks and short circuits. Additionally, fiberglass fabric is also resistant to heat, fire, and chemicals, which further enhances its suitability for electrical cable applications.

- Q: What are the different weaving patterns available for fiberglass fabric?

- There are several different weaving patterns available for fiberglass fabric, each with its own unique characteristics and applications. 1. Plain Weave: This is the most basic and commonly used weaving pattern for fiberglass fabric. It consists of a simple over-and-under interlacing of warp and weft yarns, creating a balanced and uniform fabric structure. Plain weave fiberglass fabric offers good strength, dimensional stability, and is suitable for a wide range of applications. 2. Twill Weave: Twill weave creates a diagonal pattern on the fabric surface, achieved by passing the weft yarn over multiple warp yarns before going under. This weaving pattern enhances the fabric's drapability, flexibility, and allows for better conformability to complex shapes. Twill weave fiberglass fabric is often used in applications where flexibility and durability are required, such as in the aerospace and automotive industries. 3. Satin Weave: Satin weave is characterized by long floats, where the weft yarn passes over multiple warp yarns before going under. This creates a smooth and lustrous surface with less crimp and higher yarn density. Satin weave fiberglass fabric offers excellent drapeability, high strength-to-weight ratio, and is commonly used in applications that require a high-quality surface finish, such as marine and sporting goods industries. 4. Leno Weave: Leno weave is a unique pattern where the warp yarns are twisted around each other, creating an open and flexible structure. This weaving pattern enhances the fabric's breathability and allows for better resin impregnation during composite fabrication. Leno weave fiberglass fabric is often used in applications such as filtration, reinforcement in composites, and as a base fabric for laminates. 5. Jacquard Weave: Jacquard weave is a complex pattern created by individually controlling each warp yarn. This weaving technique allows for intricate designs, patterns, and textures to be woven into the fabric. Although less common in fiberglass fabric, jacquard weave can be used to create custom designs or specific functional features in specialized applications. Overall, the choice of weaving pattern for fiberglass fabric depends on the desired properties, performance requirements, and intended applications. Each weaving pattern offers unique characteristics and advantages, allowing for a wide range of possibilities in utilizing fiberglass fabric across various industries.

- Q: How does fiberglass fabric perform in chemical resistance?

- Fiberglass fabric generally performs well in chemical resistance due to its inherent properties. It is resistant to many chemicals and solvents, making it suitable for applications where exposure to corrosive substances is a concern. However, its resistance may vary depending on the specific chemicals involved and the concentration and duration of exposure. In such cases, it is advisable to consult chemical compatibility charts or conduct laboratory tests to ensure optimal performance.

- Q: Is fiberglass fabric resistant to rot and mildew?

- Yes, fiberglass fabric is highly resistant to rot and mildew. This is because fiberglass is made from a combination of glass fibers and a polymer resin, which makes it highly resistant to moisture and fungal growth. Unlike natural fabrics such as cotton or wool, fiberglass does not provide a suitable environment for mold or mildew to grow. Additionally, fiberglass is non-porous and does not absorb water, further reducing the risk of rot or mildew formation. This makes fiberglass fabric a popular choice for applications where moisture resistance and durability are important, such as in outdoor furniture, boat covers, and automotive interiors.

- Q: How is fiberglass fabric used in the sports and recreation industry?

- Fiberglass fabric is widely used in the sports and recreation industry due to its unique properties that make it an ideal material for various applications. One of the primary uses of fiberglass fabric in this industry is for the construction of sporting equipment such as boats, surfboards, and skis. In boat building, fiberglass fabric is commonly used to reinforce the structure of the hull, providing strength and durability. The fabric is impregnated with a resin, usually epoxy or polyester, which creates a rigid and lightweight composite material. This makes fiberglass boats highly resistant to impact, water damage, and corrosion, making them suitable for various water sports such as sailing, fishing, and water skiing. Similarly, fiberglass fabric is extensively used in the production of surfboards. The fabric is layered on a foam core, and a resin is applied to create a rigid and buoyant board. Fiberglass surfboards are known for their stability, responsiveness, and durability, making them popular among surfers of all skill levels. Another area where fiberglass fabric finds application is in the manufacturing of skis and snowboards. The fabric is used as a reinforcement layer on the core of the ski or snowboard, providing torsional rigidity and strength. This enhances the performance and stability of the equipment, allowing athletes to navigate through various snow conditions with ease and control. Furthermore, fiberglass fabric is utilized in the production of sports protective gear such as helmets, shin guards, and body armor. The fabric's high tensile strength, impact resistance, and lightweight nature make it an excellent choice for enhancing the safety of athletes. Fiberglass-reinforced helmets, for example, can absorb and distribute impact forces, reducing the risk of head injuries in contact sports like football and hockey. Overall, fiberglass fabric plays a crucial role in the sports and recreation industry by providing strength, durability, and performance-enhancing properties to various equipment and protective gear. Its versatility and ability to be molded into different shapes make it a preferred material for athletes and sports enthusiasts worldwide.

Send your message to us

High Temperature Graphite Coated Fiberglass Fabric Heat Resistant Glass Cloth with Ptfe Coating

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords