Ptfe Coated Fiberglass Fabric - Heat Resistant and Fireproof Silica Fabric

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description: High silica glass fibre fabric is made by silica fiberglass fabric which is a kind of inorganic fiber contaiting more than 96% SiO2. It is high temperature resistance. Its softening point approaches 1700°C and can be used at 1000°C for a long time. It can work short-term at 1500°C. Silica fabric is applicable for use as a high temperature resistant, heat resistant, fire resistant,and corrosion resistant material.It is widely used in avaiation and aerospace, metallurgy, chemical, building material and fire fighting industry. Apart from applications requiring high temperature-resistance, it is also has insulation and fire prevention uses. Such as Thermal insulation covers, padding, lagging, welding blanket, fire curtain and other heavy duty fire control system. Silica glass fibre cloth is suitable for coating with difference elastomers and polymers.

Features: high temperature resistance,heat resistance,chemical resistance

Application: fire doors, fire curtain, welding blanket, fire blanket,heat shielding, removable insulation jackets, cover, mattress, pad,oil, gas, chemical, energy, cement industry,other fire control systems.

PRICE: USD7.5 per square meter

UNIT: square meter

MOQ: 500square meters

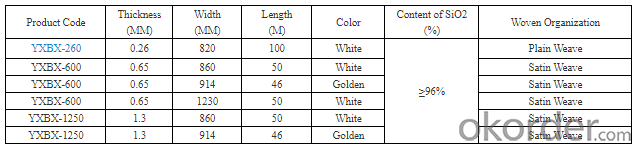

Weight: 430gsm 610gsm 1100gsm 1200gsm

Width: 1m-2m or customized

Yarn Type: E-glass

Standing temperature: 1000℃

Product name: Silica Fabric

Coating/Finish/Surface Treatment: Silica

Roll length: 50 meter or customized

Color: white, golden

Weave Type: twill woven

Alkali content: Alkali free

Processing service: cutting

Material: fiberglass

Thickness: 0.6mm, 1.1mm, 1.3mm or customized

Size: can be customized

Supply ability: 300000 meters per month

Packaging: High silica glass fibre fabric cloth rolls packed in cartons loaded on pallets or according to customers' requirements.

Lead time: 7-30 days

- Q: Can fiberglass fabric be used for making protective covers?

- Yes, fiberglass fabric can be used for making protective covers.

- Q: What are the different fiberglass fabric weights for lightweight applications?

- There are typically three different fiberglass fabric weights used for lightweight applications: 3 oz, 6 oz, and 9 oz.

- Q: Can fiberglass fabric be used for reinforcement in sports equipment?

- Yes, fiberglass fabric can be used for reinforcement in sports equipment. Fiberglass fabric is known for its high strength-to-weight ratio, making it an ideal material for reinforcing various sports equipment such as skis, snowboards, surfboards, and even tennis rackets. The fiberglass fabric is typically combined with a resin matrix to create a strong and durable composite material that can withstand the high stress and impact experienced during sports activities. Additionally, fiberglass fabric can also provide flexibility and enhance the overall performance of the equipment by improving its torsional and bending properties. Therefore, fiberglass fabric is commonly used as a reinforcement material in sports equipment to enhance their strength, durability, and performance.

- Q: Can fiberglass fabric be used for making sports jerseys?

- Yes, fiberglass fabric can be used for making sports jerseys. It is a strong and durable material that offers excellent resistance to wear and tear. However, it may not be commonly used for sports jerseys due to its lack of breathability and potential discomfort for athletes.

- Q: What are the different fiberglass fabric finishes for water resistance?

- There are several different fiberglass fabric finishes that provide water resistance. One commonly used finish is silicone, which forms a waterproof barrier on the fabric surface. Silicone-coated fiberglass fabric is highly resistant to water and can be used in various applications such as outdoor covers, tents, and boat sails. Another finish is polyurethane, which also creates a water-resistant coating on the fabric. Polyurethane-coated fiberglass fabric is often used in rainwear, backpacks, and other outdoor gear where water resistance is critical. A third option is fluoropolymer finishes, such as PTFE (polytetrafluoroethylene) or Teflon, which provide excellent water repellency. Fiberglass fabric with a fluoropolymer finish is commonly used in applications where water needs to bead up and roll off the surface, such as awnings, umbrellas, and outdoor furniture covers. Additionally, acrylic finishes can be applied to fiberglass fabric to enhance water resistance. Acrylic-coated fiberglass fabric is commonly used in marine applications, such as boat covers and biminis, as it provides good waterproofing while maintaining breathability. It is important to note that while these finishes offer water resistance, they may not provide complete waterproofing if the fabric is exposed to prolonged or heavy rain. In such cases, additional measures like seam sealing or using a waterproof membrane may be necessary to ensure full protection against water penetration.

- Q: Can fiberglass fabric be used for wall coverings?

- Fiberglass fabric has the capability to serve as wall coverings. This versatile material presents numerous advantages for wall coverings. It possesses a lightweight nature, durability, and exceptional resistance to moisture, mold, and mildew. These properties render it a perfect selection for areas prone to high humidity, such as bathrooms or kitchens. Furthermore, fiberglass fabric can be effortlessly installed on walls, either through adhesive application or stapling it onto the surface. It also allows for painting, enabling a customized finish that aligns with the desired interior design. Additionally, fiberglass fabric exhibits fire resistance, making it a safer choice for wall coverings. With a high melting point and the absence of toxic fumes emission when exposed to fire, it becomes a crucial consideration for building safety. In conclusion, fiberglass fabric emerges as a pragmatic and versatile option for wall coverings, offering both aesthetic allure and functional advantages.

- Q: Can fiberglass fabric be used for reinforcement in plastic tanks?

- Yes, fiberglass fabric can be effectively used for reinforcement in plastic tanks. Its high strength-to-weight ratio and excellent resistance to corrosion and chemicals make it an ideal material for reinforcing plastic tanks, improving their structural integrity and durability.

- Q: How is fiberglass fabric used in the production of thermal curtains?

- Due to its unique properties and benefits, fiberglass fabric is commonly utilized in the manufacturing of thermal curtains. One of its notable attributes is excellent insulation, making it an ideal material for thermal curtains. By acting as a barrier against heat transfer, the fabric helps maintain a consistent temperature indoors. In the production of thermal curtains, fiberglass fabric often serves as a lining or interlining. It is positioned between the decorative outer fabric and the inner lining of the curtain, providing an additional layer of insulation. This layer effectively prevents heat loss during winter and heat gain in summer. Moreover, fiberglass fabric is lightweight and flexible, facilitating easy handling during the manufacturing process. It can be effortlessly cut, sewn, and tailored to fit curtains of various sizes and designs. Furthermore, its durability ensures that thermal curtains made with fiberglass fabric withstand frequent use while maintaining their insulating properties over time. Additionally, fiberglass fabric is fire-resistant, enhancing the safety of thermal curtains. This property plays a crucial role in preventing the spread of fire and safeguarding occupants during emergencies. Overall, fiberglass fabric is an indispensable component in the production of thermal curtains. Its insulation, lightweight nature, flexibility, durability, and fire resistance make it an ideal choice for creating curtains that effectively regulate temperature, conserve energy, and enhance comfort in residential and commercial spaces.

- Q: What is the average thickness of fiberglass fabric?

- Depending on the specific application and manufacturing process, the average thickness of fiberglass fabric can vary. Typically, the thickness of fiberglass fabric ranges from 0.2 millimeters (0.008 inches) to 0.5 millimeters (0.02 inches).

- Q: How does fiberglass fabric perform in terms of flexibility?

- Exceptional flexibility is a characteristic for which fiberglass fabric is well known. Its composition of fine glass fibers allows for easy molding and bending into various shapes and contours, all while maintaining its structural integrity. This quality of flexibility makes fiberglass fabric highly versatile, making it suitable for a wide range of applications. Industries such as automotive, aerospace, construction, and even fashion benefit from its adaptability. Moreover, fiberglass fabric's durability is demonstrated by its ability to withstand repeated bending and stretching without significant wear and tear. This durability makes it an ideal choice for projects that require long-term flexibility. In conclusion, fiberglass fabric offers designers and manufacturers the freedom to create innovative and dynamic products, thanks to its exceptional performance in terms of flexibility.

Send your message to us

Ptfe Coated Fiberglass Fabric - Heat Resistant and Fireproof Silica Fabric

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords