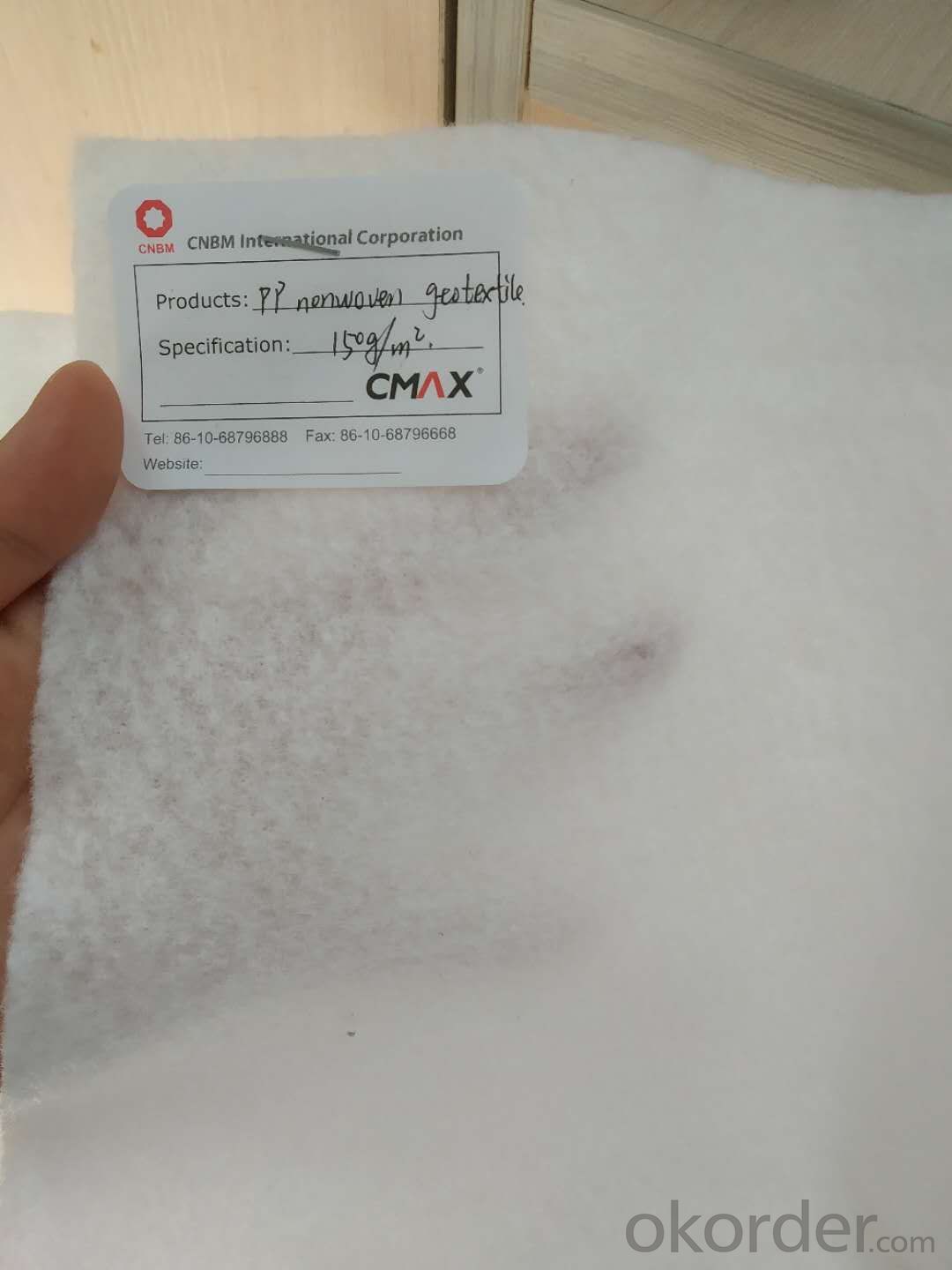

High Strength PP Non-woven Geotextile for River Bank Protection

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of High Strength Nonwoven Geotextile

CMAX polypropylene non woven geotextile is made from high strength polypropylene short fiber by non woven needle punched manufacturing process. It has separation, filtration, drainage, reinforcement, protection and maintenance etc. function

2. Specification of High Strength Nonwoven Geotextile

Weight: 100gsm – 1200gsm;

Material: 100% polypropylene

Width: 1m – 6m; Length: as clients’ required.

Color:black, white,beige, green

3. Technical Data Sheet of High Strength nonwoven geotextile

Item | Unit | Index | ||||||||

Weight per Square Meter | g/m2 | 100 | 200 | 300 | 400 | 500 | 600 | 800 | 1000 | |

Grab | MD | N | ≥350 | ≥700 | ≥1100 | ≥1400 | ≥1800 | ≥2200 | ≥2800 | ≥3400 |

CD | ≥350 | ≥700 | ≥1100 | ≥1400 | ≥1800 | ≥2200 | ≥2800 | ≥3400 | ||

Elongation | MD | % | 50~90 | 50~100 | ||||||

CD | 50~90 | 50~100 | ||||||||

Trapezoidal Tearing Strength | MD | N | ≥135 | ≥280 | ≥350 | ≥400 | ≥480 | ≥550 | ≥650 | ≥750 |

CD | ≥135 | ≥280 | ≥350 | ≥400 | ≥480 | ≥550 | ≥650 | ≥750 | ||

CBR Mullen Burst Strength KN | KN | ≥1.0 | ≥2.1 | ≥3.2 | ≥3.8 | ≥4.5 | ≥5.5 | ≥6.5 | ≥7.5 | |

Tearing Strength | MD | KN | ≥3.5 | ≥8 | ≥12 | ≥18 | ≥24 | ≥30 | ≥40 | ≥50 |

CD | ≥3.5 | ≥8 | ≥12 | ≥18 | ≥24 | ≥30 | ≥40 | ≥50 | ||

Break Strength | MD | % | 40~65 | 50~80 | ||||||

CD | 40~65 | 50~80 | ||||||||

Puncturing Strength | N | ≥180 | ≥360 | ≥550 | ≥750 | ≥900 | ≥1150 | ≥1450 | ≥2000 | |

Peeling Strength | N/5 cm | ≥80 | ≥100 | |||||||

Antiacid alkali-resistant | % | ≥90% | ||||||||

Seive Size O90 | Mm | ≤0.1 | ||||||||

Vertical Permeability | Cm/s | ≤0.2 | ||||||||

4. Property of High Strength Nonwoven Geotextile

1).The mechanical values are 2-3 times more than ordinary products.

2).Good acid and alkali resistance, excellent hot melting adhesiveness, high anti-abrasion performance.

5. Application of High Strength Nonwoven Geotextile

1) Filtration of soils in drainage applications by retaining soil particles while allowing for the free flow of water.

2) Separation and stabilization in road and railway constructions.

3) Prevention of soil movement in erosion control measures.

4) Cushioning and protection in many containment projects

RFQ:

What is the main application of Non-woven Geotextile for River Bank Protection?

The main application of Non-woven Geotextile for River Bank Protection is as follows: The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc.

Where is your main market?

Our main market is in Middle East, South America and some African countries.

What is your advantages for the S Non-woven Geotextile for River Bank Protection?

One of the largest manufacturer of Short Fiber Nonwoven Geotextile with advanced equipment, big production capacity and excellent quality.

- Q: How do geotextiles improve the performance of slopes?

- Geotextiles improve the performance of slopes by providing erosion control, stabilization, and reinforcement. These synthetic fabrics are installed between the soil layers of the slope, acting as a barrier to prevent soil movement and erosion caused by water flow or wind. Geotextiles also enhance the overall stability of the slope by improving soil drainage, reducing pore water pressure, and increasing soil strength.

- Q: How do geotextiles help in the reinforcement of soil?

- Geotextiles help in the reinforcement of soil by providing stability and strength to the soil structure. They act as a barrier between different soil layers, preventing their mixing and maintaining their integrity. Geotextiles also distribute the load evenly across the soil, reducing the risk of settlement or subsidence. Additionally, they improve drainage and filtration by allowing water to pass through while preventing the loss of fine particles. Overall, geotextiles enhance the overall performance and longevity of soil in various engineering and construction applications.

- Q: Seepage geotextile symbol

- At present, the engineering commonly used seepage geotextile is divided into polyester staple geotextile and polyester filament geotextile two. Polyester staple geotextile identification symbol for the SNG, for example, 150g / ㎡ polyester staple geotextile can be expressed as SNG150. Polyester filament geotextile identification symbol for the FNG, for example, 200g / ㎡ of polyester filament geotextile can be expressed as FNG200. In the national standard in the seepage geotextile on the permeability of the test items are equivalent pore size O90 (95) / mm and vertical permeability coefficient CM / S two.

- Q: Geotextile with the welding tool where to buy

- Local Hardware & Electrical City, about 5000 or so

- Q: Can geotextiles be used in green roof systems?

- Yes, geotextiles can be used in green roof systems. Geotextiles are often used as a protective layer between the roof membrane and the growing medium or drainage layer in green roof systems. They help prevent clogging, promote water drainage, and provide additional reinforcement to the roof structure.

- Q: We are scrambling to sell geotextiles, recommended geotextile. What is the principle of geotextile seepage? Why can geotextile seepage? More

- Geotextile definition is too broad, and anti-seepage is mainly refers to the PE film

- Q: what is the life span of a geotextile tube ?

- Engineered geotextiles have design lives of up to 120yrs. It depends on what geotextile you are talking about and what environment it is placed in.

- Q: Are geotextiles resistant to hydraulic shear stress?

- Yes, geotextiles are designed to be resistant to hydraulic shear stress. They have the ability to withstand the forces generated by flowing water, preventing erosion and maintaining soil stability.

- Q: Geotextile moisture-proof layer: 200 cloth +400 film +200 cloth

- You are not to composite geomembrane, I was specializing in the production of geotechnical materials, account number that phone

- Q: Are geotextiles suitable for use in canal lining?

- Yes, geotextiles are suitable for use in canal lining. They provide effective erosion control and filtration, preventing soil loss and allowing water to flow through while retaining fines. Geotextiles also offer durability, resistance to UV degradation, and can be installed easily.

Send your message to us

High Strength PP Non-woven Geotextile for River Bank Protection

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords