High Tensile Strength PP Nonwoven Geotextile for Cilvil Engineering Project Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of PP Nonwoven Geotextile

CMAX polypropylene non woven geotextile is made from high strength polypropylene short fiber by non woven needle punched manufacturing process. It has separation, filtration, drainage, reinforcement, protection and maintenance etc. function.

Specifications of PP Nonwoven Geotextile

Weight: 100gsm – 1200gsm;

Material:PP, PET

Width: 1m – 6m; Length: as clients’ required

Color: black, white

Technical Data Sheet of PP Nonwoven Geotextile

Item | Unit | Index | ||||||||

Weight per Square Meter | g/m2 | 100 | 200 | 300 | 400 | 500 | 600 | 800 | 1000 | |

Grab | MD | N | ≥350 | ≥700 | ≥1100 | ≥1400 | ≥1800 | ≥2200 | ≥2800 | ≥3400 |

CD | ≥350 | ≥700 | ≥1100 | ≥1400 | ≥1800 | ≥2200 | ≥2800 | ≥3400 | ||

Elongation | MD | % | 50~90 | 50~100 | ||||||

CD | 50~90 | 50~100 | ||||||||

Trapezoidal Tearing Strength | MD | N | ≥135 | ≥280 | ≥350 | ≥400 | ≥480 | ≥550 | ≥650 | ≥750 |

CD | ≥135 | ≥280 | ≥350 | ≥400 | ≥480 | ≥550 | ≥650 | ≥750 | ||

CBR Mullen Burst Strength KN | KN | ≥1.0 | ≥2.1 | ≥3.2 | ≥3.8 | ≥4.5 | ≥5.5 | ≥6.5 | ≥7.5 | |

Tearing Strength | MD | KN | ≥3.5 | ≥8 | ≥12 | ≥18 | ≥24 | ≥30 | ≥40 | ≥50 |

CD | ≥3.5 | ≥8 | ≥12 | ≥18 | ≥24 | ≥30 | ≥40 | ≥50 | ||

Break Strength | MD | % | 40~65 | 50~80 | ||||||

CD | 40~65 | 50~80 | ||||||||

Puncturing Strength | N | ≥180 | ≥360 | ≥550 | ≥750 | ≥900 | ≥1150 | ≥1450 | ≥2000 | |

Peeling Strength | N/5 cm | ≥80 | ≥100 | |||||||

Antiacid alkali-resistant | % | ≥90% | ||||||||

Seive Size O90 | Mm | ≤0.1 | ||||||||

Vertical Permeability | Cm/s | ≤0.2 | ||||||||

Property of PP Nonwoven Geotextile

1).The mechanical values are 2-3 times more than ordinary products.

2).Good acid and alkali resistance, excellent hot melting adhesiveness, high anti-abrasion performance.

Application of PP Nonwoven Geotextile

1) Filtration of soils in drainage applications by retaining soil particles while allowing for the free flow of water.

2) Separation and stabilization in road and railway constructions.

3) Prevention of soil movement in erosion control measures.

4) Cushioning and protection in many containment projects.

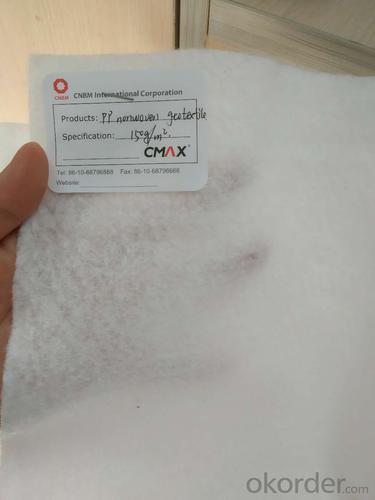

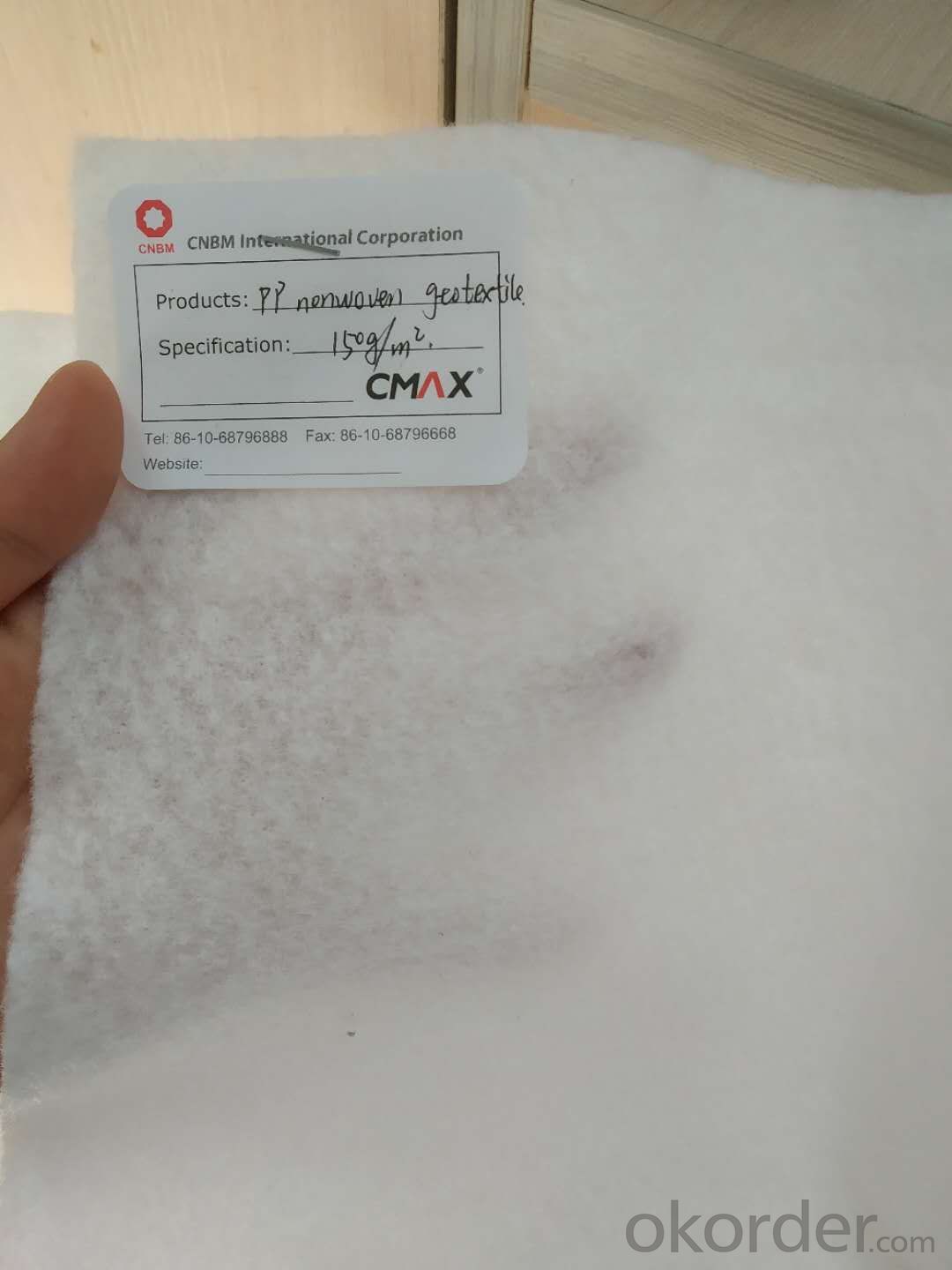

Product photos:

FAQ

1. How about the delivery time?

Lead time since receipt of 30% T/T deposit payment: 3 weeks.

2. What kind of payments does jenor support?

T/T, L/C, Cash are accepted.

3. What's are the MOQ?

We can according to your condition to set the MOQ.

And we can provide you samples for quality inspection.

4. Do you charge for the samples?

Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee If you set the order .

5. Can you produce the product according to customers' requirements ?

Sure, we are professional manufacturer, OEM and ODM are both welcome.

6. Can you tell me your main customers?

That's our customers' privacy, we should protect their information. At the same time, please rest assured that your information is also safe here.

- Q: Geotextile 300g * 600mm * 300g is how is it?

- No you say 300g * 600mm * 300g this specification of the product, according to reason should be 300g * 0.6mm * 300g product 300g * 0.6mm * 300g product is a composite geomembrane specifications, also known as two cloth a film , Composite geotextile. That is, both sides of the upper and lower sides of a layer of 300g geotextile, the middle folder 0.6mm thickness of the plastic film. Composite geomembrane is to play the role of anti-seepage, generally used for water conservancy project seepage, civil engineering seepage and so on. The geotextile is from the water, reinforcement, protection, and can not achieve the role of anti-seepage. 300g * 0.6mm * 300g composite geomembrane price is generally between 11.5-13 yuan. You can do the next reference.

- Q: Can geotextiles be used in groundwater control?

- Yes, geotextiles can be used in groundwater control. They are commonly employed as part of drainage systems to filter and separate different layers of soil, preventing the clogging and migration of fine particles. Geotextiles can also be used in conjunction with geosynthetics to create impermeable barriers, preventing the seepage or flow of groundwater in certain applications.

- Q: Can geotextiles be used for slope stabilization?

- Yes, geotextiles can be used for slope stabilization. Geotextiles are commonly used in civil engineering projects to reinforce soil and prevent erosion. By placing geotextiles on slopes, they can provide stability by distributing the forces acting on the slope and improving soil cohesion. Additionally, geotextiles can help with drainage, filtration, and vegetation growth, further enhancing slope stability.

- Q: GB / T-2008 has this standard on staple geotextile? What is the exact name? Know what to say thank you!

- Is the new 2008 standard out?

- Q: What are the cost implications of using geotextiles?

- The cost implications of using geotextiles can vary depending on several factors. Initially, the upfront cost of geotextiles may be higher compared to traditional materials. However, geotextiles can provide long-term cost savings by extending the lifespan of infrastructure and reducing maintenance and repair expenses. Additionally, geotextiles can eliminate the need for costly excavation and disposal of contaminated soil. Considering these factors, while geotextiles may have higher initial costs, they can result in overall savings throughout the lifespan of a project.

- Q: How long do geotextiles last?

- Geotextiles can last anywhere from 5 to 25 years, depending on various factors such as the quality of the material, environmental conditions, and the specific application they are used for.

- Q: How do geotextiles aid in the reduction of frost heave?

- Geotextiles aid in the reduction of frost heave by providing a barrier between the soil and the freezing temperatures, which helps to prevent the migration of water and the subsequent expansion of ice within the soil. This helps to minimize the upward pressure that causes frost heave, ultimately reducing the potential damage to structures or infrastructure.

- Q: Are geotextiles resistant to extreme temperatures?

- Yes, geotextiles are generally resistant to extreme temperatures. They are designed to withstand a wide range of temperatures, both hot and cold, without significant degradation or loss of performance.

- Q: Are geotextiles suitable for use in dam construction?

- Yes, geotextiles are suitable for use in dam construction. They are commonly used as a filter or separation layer to prevent soil erosion, control seepage, and enhance the stability of the dam structure. Geotextiles have proven to be effective in reinforcing soils, improving drainage, and providing long-term durability, making them a valuable component in dam construction projects.

- Q: What are the factors to consider when selecting geotextiles?

- When selecting geotextiles, some important factors to consider include the type of project or application, the required strength and durability, the desired permeability and filtration properties, the site conditions such as soil type and slope, the installation and maintenance requirements, as well as cost-effectiveness.

Send your message to us

High Tensile Strength PP Nonwoven Geotextile for Cilvil Engineering Project Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords