High Strength HDPE Uniaxial Geogrid for Europe Geogrids Market

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

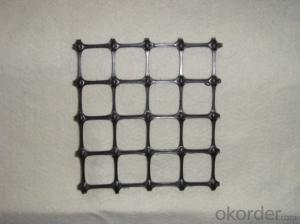

HDPE Uniaxial Geogrid Introduction

25-25KN,30-30KN,50-50KN,80-80KN,100-100KN,120-120KN,150-150KN,200-200KN

Width≤6m; Length 50m or as requested

HDPE Uniaxial Geogrid Features

1. In high tensile strength

2. Low elongation

3. Anti-erosion, anti-aging

4. Light weight, structural uniformity, easy for construction

5. Flame retardant, anti-static, good overall performance, easy for mechanized operation

6. Good affinity with base materials

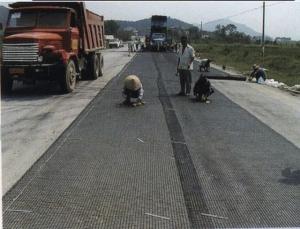

HDPE Uniaxial Geogrid Application

ation

1. Roadbed reinforcement in highway, railway and municipal road

2. Reinforcement and separation in dam and river, improving soft soil bearing capacity and stability

3. Roadbed slope reinforcement, retaining wall reinforcement

HDPE Uniaxial Geogrid Specification

Technical Data

Item | Specification and Index | ||||||

30-30 | 35-35 | 50-50 | 80-80 | 100-100 | 125-125 | 150-150 | |

Limit Tensile Strength (MD&TD)(KN/m) | ≥30 | ≥35 | ≥50 | ≥80 | ≥100 | ≥125 | ≥150 |

Elongation at nominal tensile strength (MD&TD)(%) | ≤13 | ≤13 | ≤13 | ≤13 | ≤13 | ≤13 | ≤14 |

Tensile Strength@2% elongation(MD&TD)(KN/m) | ≥10 | ≥12 | ≥17 | ≥28 | ≥35 | ≥43 | ≥52 |

Tensile Strength@5% elongation(MD&TD)(KN/m) | ≥20 | ≥24 | ≥34 | ≥56 | ≥70 | ≥86 | ≥104 |

Production Standard : JT/T480-2002 | |||||||

FAQ

1. What's the usage of geogrid?

It's used for reinforce the roadbeds in softe soil, railway, tunnel, slope and embankment etc. It has good performance on preventing the cracks.

2. How about your quality of geogrid?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world.

- Q: Geosynthetic materials for flood control materials

- Geosynthetics can be divided into geotextile, geomembrane and geotextile composite materials, special geotechnical materials 4 categories: fabric is a kind of porous material, with polypropylene, polyester and nylon and other synthetic fiber materials, according to the production method can be divided into shape, fabric two other non woven. The fabric style is to use a series of single chain according to a certain way woven, generally by the orthogonal warp and weft two group fiber woven fabric; non plastic geotextile is made of short fiber and long fiber directional or random order, by acupuncture or thermal bonding, chemical bonding, the biggest characteristic the strength is no obvious direction, so its use is wide.The aging rate of geotextiles is closely related to the intensity, temperature, humidity, the type and color of the raw materials, the structure of the fabric and the environmental conditions.

- Q: Are geogrids effective in preventing soil erosion on slopes with vegetation?

- Yes, geogrids are effective in preventing soil erosion on slopes with vegetation. Geogrids provide structural support to the soil, preventing it from being washed away by water or blown away by wind. This helps to maintain the stability of the slope and protects the vegetation from being uprooted. Additionally, geogrids help to reinforce the root systems of plants, enhancing their ability to hold the soil in place. Overall, geogrids are a valuable tool in preventing soil erosion on slopes with vegetation.

- Q: Can geogrids be used in reinforcement of soft ground?

- Yes, geogrids can be used in the reinforcement of soft ground. Geogrids are commonly used to improve the stability and load-bearing capacity of weak or soft soil by distributing the applied loads and reducing settlement. They are effective in reinforcing soft ground and can provide increased strength and stability to the soil, making them a suitable solution for various civil engineering and construction projects.

- Q: Can geogrids be used in reinforcement of mechanically stabilized earth bridge piers?

- Yes, geogrids can be used in the reinforcement of mechanically stabilized earth bridge piers. Geogrids are commonly used in geotechnical engineering for soil reinforcement and stabilization. They can enhance the structural integrity of the bridge piers by providing additional tensile strength and preventing soil movement.

- Q: What is the recommended spacing between geogrid layers?

- The recommended spacing between geogrid layers can vary depending on the specific application and design requirements. However, in general, a spacing of about 1 to 2 feet (30 to 60 centimeters) is often recommended. This allows for proper interlocking and interaction between the geogrid layers, ensuring optimal load distribution and stability. It is important to consult with a geotechnical engineer or follow the manufacturer's guidelines to determine the appropriate spacing for a particular project.

- Q: Who can elaborate on the highway construction steps, as well as laying materials, the more detailed the better!!!

- The specifications are as follows: Geogrid TGDG25 TGDG35 TGDG50 TGDG80 TGDG110 TGDG120 TGDG150 width of 1 meters -3 meters; bidirectional geogrid TGSG20-20 width 2.5-5m TGSG15-15 TGSG25-25 TGSG30-30 TGSG40-40 GS30-30 GS50-50 m; plastic composite grid GS60-60 GS80-80 GS80-60 GS150-150 width 4-6m meters; BJG35-35 BJG50-50 BJG60-60 BJG80-80 glassgrid width 4-6 meters;

- Q: How do geogrids improve the performance of geosynthetic-reinforced slopes in liquefaction-prone areas?

- Geogrids improve the performance of geosynthetic-reinforced slopes in liquefaction-prone areas by providing additional stability and reinforcement to the soil. They function by distributing and transferring the load across a wider area, reducing the potential for soil liquefaction. Additionally, geogrids increase the shear strength of the soil, preventing slope failure and enhancing the overall stability of the structure.

- Q: How many square meters of steel plastic geogrid inspection

- Under normal circumstances, the detection of steel plastic geogrid is 10 thousand square meters. The specific quantity shall be subject to the supervision personnel.

- Q: Are geogrids resistant to fire?

- No, geogrids are not generally resistant to fire.

- Q: How to do a good job ah? How to start the sale of geotechnical materials

- Everything is difficult at the beginning, and now the competition in the field of materials industry has entered a white hot, slowly come, more run the site, running more than the site, will naturally..

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 15.00% South America 15.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 80,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

High Strength HDPE Uniaxial Geogrid for Europe Geogrids Market

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords