Interlock Fiberglass Geogrids with CE ISO Certification

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid With CE ISO certification

Intriduction of Fiberglass Geogrid:

CMAX fiberglass georid is based on fiberglass woven cloth with modified bitumen or PVC, it was developed to address the problem of pavement cracing on highways, roads and runways, driven by a need to reduce cost for infrastructure maintanance and repair.

It is a characterized by high tensile strength in axial and lateral direcions,low stretch rate, alkali-resistance, low temperature-resistance, as well as convenience in construction and low price. It can be on pitch pavement to prevent cracks and prolong pavement service life. It also can be used as a basal reinforcement material for hillsides, reservoirs,harbors,ports,water channels,seawalls,etc.

Advantages of Fiberglass Geogrid:

High strength, high modulus and low temperatures resistance.

Applications of Fiberglass Geogrid:

1. It reinforces old asphalt concrete road surface and asphalt surface layer, and prevents damage;

2. it used for rebuilding cement concrete road surface into composite road surface and restraining reflection caused by block contraction;

3. it is used in road expansion and improvement project and crack caused by old and new combination position and uneven sedimentation;

4. it is used in soft soil base reinforcement treatment ,is favorable for soft soil water separation and concretion, restrains sedimentation effectively, distributes stress uniformly and improve overall strength of road base;

5. it is used for preventing contraction crack caused by new road semi-rigid base layer, and reinforcing and preventing road surface crack caused by foundation crack reflection

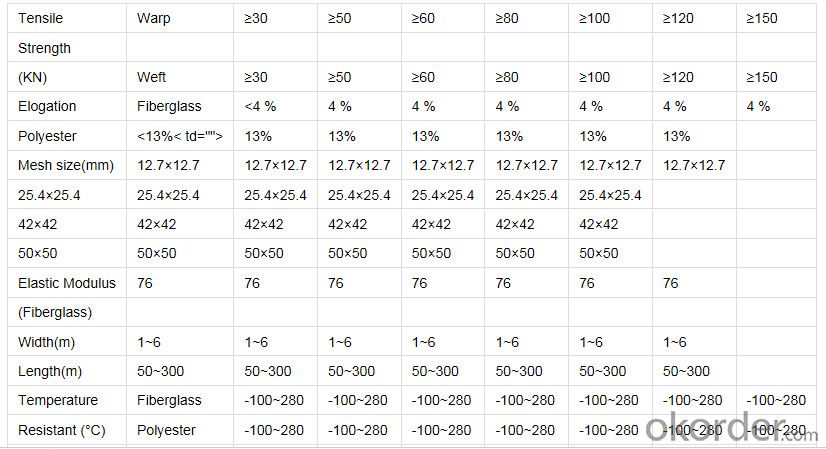

Specifications of Fiberglass Geogrid:

FAQ:

1. Which payment do you accept?

For you convinience,our payment can be L/C,TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Our products are with much higher standard than Chinese standard, and it can reach CE certification. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world.

Photos of Fiberglass Geogrid:

- Q: What are the advantages of using geogrids in construction projects?

- Geogrids offer several advantages in construction projects. Firstly, they provide reinforcement to the soil, increasing its stability and load-bearing capacity. This helps to prevent soil erosion, slope failures, and settlement issues. Secondly, geogrids are cost-effective as they reduce the need for extensive excavation and the use of additional materials. They also facilitate faster construction time as they can be easily installed. Additionally, geogrids are durable and resistant to environmental degradation, ensuring long-term performance and reduced maintenance. Overall, the use of geogrids in construction projects leads to improved safety, enhanced structural integrity, and cost savings.

- Q: Can geogrids be used in riverbank protection projects?

- Yes, geogrids can be used in riverbank protection projects. Geogrids are commonly employed in such projects to provide soil stabilization, erosion control, and reinforcement to prevent bank erosion and maintain the integrity of the riverbank. They enhance the stability of the soil and provide a barrier against water flow, making them an effective solution for protecting riverbanks.

- Q: What is the typical thickness of a geogrid?

- The typical thickness of a geogrid can vary depending on the specific application and requirements. However, geogrids are commonly available in thicknesses ranging from 0.5 to 2 millimeters.

- Q: How do geogrids enhance the stability of railway track cuttings?

- Geogrids enhance the stability of railway track cuttings by providing reinforcement to the soil. They are placed within the soil layers of the cutting and act as a strong and flexible support system. Geogrids distribute the load more evenly, reducing the stress on the soil and preventing its movement. This helps to prevent slope failures, soil erosion, and overall instability, ensuring the long-term stability and safety of the railway track cuttings.

- Q: What kind of experiments need to be done to check geogrid

- Review of the general test or the original detection of the project, but the general requirement to double the number of detection. That is, if there is a sample test is not qualified, then the general review is to extract two samples from the original test material to re check.

- Q: Are geogrids suitable for use in mine tailings containment?

- Yes, geogrids are suitable for use in mine tailings containment. Geogrids are commonly used in soil stabilization and reinforcement applications, and their high tensile strength and durability make them effective in preventing soil erosion and improving the stability of mine tailings containment structures. Additionally, geogrids can enhance the overall performance and longevity of the containment system by providing reinforcement to the soil and reducing the risk of slope failure or structural deformation.

- Q: The geogrid is not less than 3 meters on each side, what does it mean?

- If each side is folded three meters, then it is folded. Design requirements are clearly not for this purpose,

- Q: What is the effect of installation spacing on geogrid behavior?

- The effect of installation spacing on geogrid behavior is that it influences the overall performance and effectiveness of the geogrid in reinforcing soil. The spacing between individual geogrids affects their ability to distribute loads evenly, provide adequate confinement to the soil particles, and enhance interlocking mechanisms. Proper installation spacing ensures optimal stress distribution, reduces differential settlement, and improves overall stability and load-bearing capacity of the reinforced soil structure.

- Q: The difference between steel plastic two-way geogrid and steel plastic geogrid

- Two way steel plastic geogrid is horizontal and vertical tension requirements

- Q: What are the models and specifications of Geogrid for road

- But the specifications are not necessarily the same as the national standard.

Send your message to us

Interlock Fiberglass Geogrids with CE ISO Certification

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords