FRP Pultrusion Profiles - High Strength, Corrosion Resistant, and Fire Resistant for Platform with Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m²

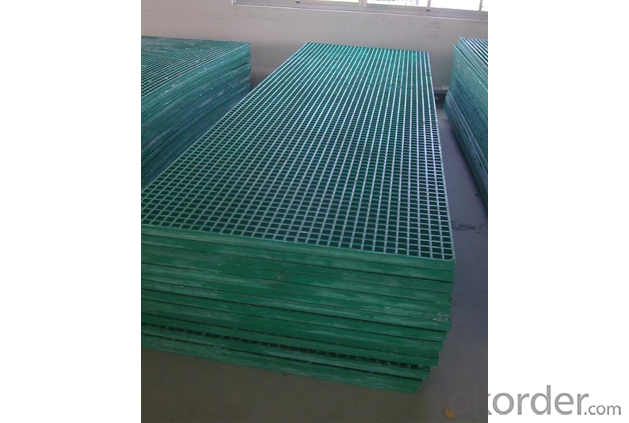

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

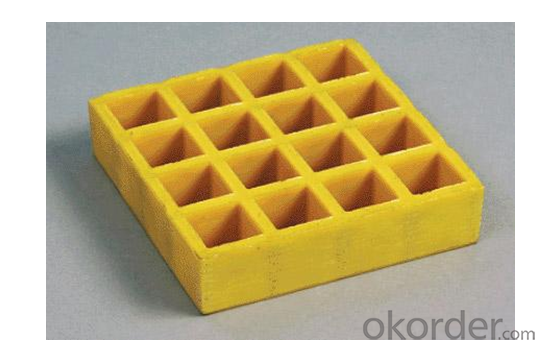

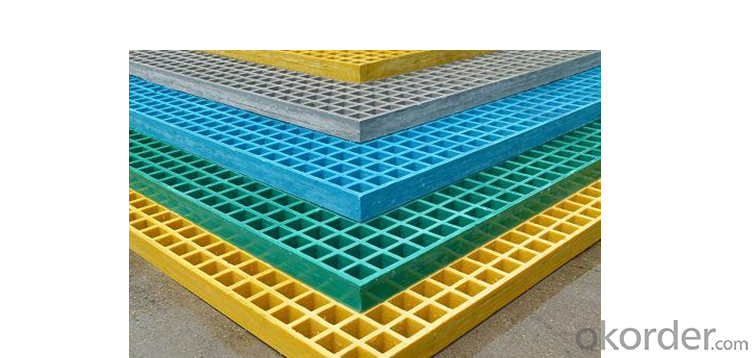

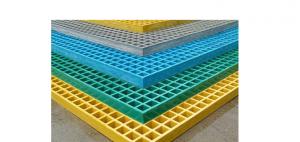

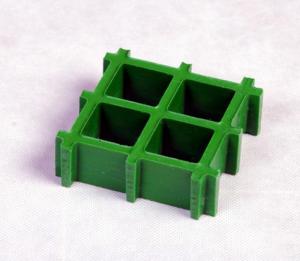

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

Fire Resistance

Light Weight & High Strength

Aging Resistance

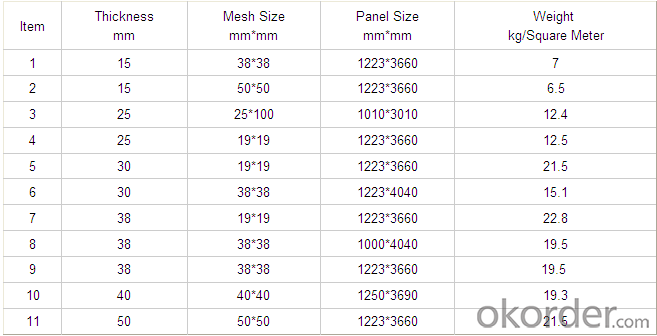

Specification

Advantage

coated with prevent aging layer

excellent insulating performance

no maintenance

Application

Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

- FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

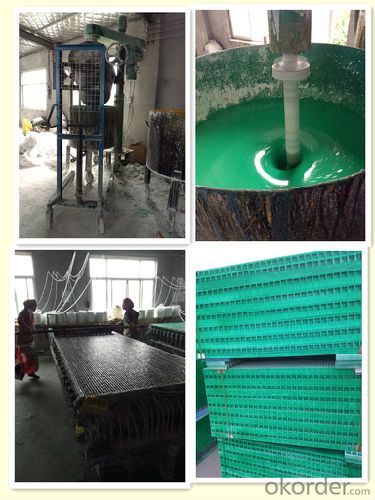

FACTORY

- Q: Are FRP pultrusion profiles resistant to biological growth, such as mold or mildew?

- Yes, FRP pultrusion profiles are highly resistant to biological growth, including mold and mildew. The inherent properties of the fiberglass reinforced polymer make it highly durable and immune to the growth of microorganisms. This resistance makes FRP pultrusion profiles ideal for applications in moist or humid environments where mold or mildew growth is common.

- Q: Can not use glass steel support column, the main support for the door

- Can not. Strength is not good. It is recommended to use FRP for exterior decoration, with steel skeleton inside.

- Q: What are the maintenance requirements for FRP pultrusion profiles?

- FRP pultrusion profiles have low maintenance requirements due to their durability and resistance to corrosion. They are a low-maintenance choice for various applications. However, there are a few important maintenance practices that can help prolong their lifespan and ensure optimal performance. Firstly, it is important to periodically clean the profiles to remove dirt, dust, and debris. This can be achieved by using a mild detergent solution and a soft brush or cloth. It is advisable to avoid abrasive cleaners or materials that could scratch the surface. Regular visual inspections should also be conducted to identify any signs of damage or wear. Cracks, chips, delamination, or any other visible defects should be promptly addressed to prevent further damage. While FRP pultrusion profiles are generally resistant to UV radiation, prolonged exposure to direct sunlight can cause some degradation. Applying a UV protective coating or using a UV-resistant paint can minimize the effects of UV exposure and extend the profiles' lifespan. For pultrusion profiles with moving parts or connections, such as hinges or joints, it is important to apply a suitable lubricant to ensure smooth operation and prevent friction-related issues. It is crucial to use lubricants compatible with FRP materials to avoid any adverse chemical reactions. In the event of significant damage or wear, it may be necessary to repair or replace the affected sections of the FRP pultrusion profiles. Trained professionals with experience working with FRP materials should perform this task to ensure proper repair techniques and maintain structural integrity. In conclusion, while FRP pultrusion profiles require minimal maintenance, regular cleaning, inspection, and prompt addressing of issues are crucial for their longevity and optimal performance. By following these maintenance practices, the lifespan of FRP pultrusion profiles can be maximized while maintaining their structural integrity over time.

- Q: Can FRP pultrusion profiles be used in the construction of industrial flooring?

- Indeed, the utilization of FRP (Fiber Reinforced Polymer) pultrusion profiles is viable in the construction of industrial flooring. These profiles are comprised of a composite material, combining robust fibers (usually glass or carbon) with a polymer resin. This amalgamation of materials imparts exceptional strength, durability, and resistance to corrosion, rendering FRP profiles highly suitable for industrial flooring applications. The primary benefit of FRP pultrusion profiles lies in their remarkable strength-to-weight ratio. Consequently, they are lighter and more manageable compared to conventional materials like steel or concrete. Moreover, FRP profiles possess non-conductive and non-magnetic properties, offering advantages in specific industrial environments. FRP pultrusion profiles also exhibit high resistance to various chemicals, moisture, and UV radiation, making them an ideal choice for harsh and corrosive settings. Unlike steel, they do not rust or corrode, nor are they affected by moisture or rot like wood. As a result, they ensure long-lasting performance and necessitate minimal maintenance. Additionally, FRP profiles can be customized and manufactured in diverse shapes, sizes, and load-bearing capacities to meet specific industrial flooring requirements. They can be designed to withstand heavy loads, impact, vibration, and other dynamic forces commonly encountered in industrial settings. In conclusion, FRP pultrusion profiles offer numerous advantages that make them well-suited for the construction of industrial flooring. Their high strength, durability, corrosion resistance, and customizable nature make them a dependable and cost-effective choice for industrial flooring applications.

- Q: Are FRP pultrusion profiles suitable for the manufacturing of chemical reactors?

- Yes, FRP pultrusion profiles are suitable for the manufacturing of chemical reactors. FRP (Fiber Reinforced Polymer) pultrusion profiles offer excellent resistance to corrosion, high strength-to-weight ratio, and dimensional stability, making them ideal for use in chemical reactors. Additionally, FRP materials can withstand a wide range of chemical environments and temperatures, making them a reliable choice for this application.

- Q: Are FRP pultrusion profiles fire resistant?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are fire resistant. The combination of the reinforcing fibers and the polymer matrix used in FRP pultrusion profiles provide them with excellent fire resistance properties. These profiles are manufactured using a process known as pultrusion, which involves impregnating reinforcing fibers such as fiberglass or carbon fiber with a thermosetting resin. This resin undergoes a curing process, resulting in a strong and durable composite material. One of the key advantages of FRP pultrusion profiles is their inherent fire resistance. The thermosetting resin used in the manufacturing process has properties that make it highly resistant to fire. When exposed to flames or high temperatures, the resin does not melt or burn easily, thus preventing the spread of fire. Additionally, the reinforcing fibers in FRP profiles also contribute to their fire resistance. Fiberglass, for example, is an inorganic material that does not burn. It acts as a barrier against heat transfer and helps to minimize the spread of flames. Furthermore, FRP pultrusion profiles can be engineered to meet specific fire safety standards and regulations. By incorporating additional fire retardant additives or using specialized resin systems, the fire resistance of these profiles can be further enhanced. It is important to note that while FRP pultrusion profiles are fire resistant, their exact fire rating may vary depending on the specific composition and design. Therefore, it is essential to consult with manufacturers or suppliers who can provide detailed information about the fire resistance properties of their FRP pultrusion profiles.

- Q: Are FRP pultrusion profiles suitable for the manufacturing of boat hulls?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are suitable for the manufacturing of boat hulls. Their high strength-to-weight ratio, corrosion resistance, and durability make them an ideal choice for boat construction. Additionally, pultruded profiles can be customized to meet specific design requirements and offer excellent dimensional stability, making them a reliable option for boat hull manufacturing.

- Q: Are FRP pultrusion profiles resistant to nitric acid?

- FRP pultrusion profiles exhibit a general resistance to nitric acid. Nitric acid, being a potent oxidizing agent, has the ability to corrode various materials, including metals. However, the construction of FRP pultrusion profiles involves the use of composite materials that are specifically engineered to withstand the effects of corrosive substances, including nitric acid. The resilience of FRP pultrusion profiles against corrosion is attributed to the combination of reinforcing fibers, such as fiberglass or carbon fiber, and a resin matrix that securely binds these fibers together. The resin matrix, typically a thermosetting polymer like polyester or epoxy, forms a protective barrier that shields the profiles from corrosive substances. Nitric acid is renowned for its capacity to corrode and deteriorate metals. Nonetheless, FRP pultrusion profiles exhibit exceptional resistance to nitric acid due to the inert nature of the composite materials employed. The reinforcing fibers utilized in FRP profiles do not react with nitric acid, while the resin matrix effectively prevents the acid from reaching and corroding the fibers by acting as a barrier. It is essential to acknowledge that the specific resistance of FRP pultrusion profiles to nitric acid may vary depending on the precise composition of the composite materials utilized, as well as the concentration and temperature of the nitric acid. Therefore, it is always advisable to consult the manufacturer or supplier of FRP profiles to ensure their compatibility with nitric acid in specific applications.

- Q: Are FRP pultrusion profiles resistant to chemicals used in pharmaceutical packaging?

- Yes, FRP pultrusion profiles are highly resistant to chemicals used in pharmaceutical packaging. The unique properties of fiberglass reinforced plastic, such as its corrosion resistance and non-reactivity to most chemicals, make FRP pultrusion profiles an ideal choice for pharmaceutical packaging applications.

- Q: What are the mechanical properties of FRP pultrusion profiles?

- FRP pultrusion profiles are highly valued in various industries due to their desirable mechanical properties. Some of the key properties include the following: 1. Exceptional Strength: FRP profiles have impressive tensile and flexural strength, making them suitable for load-bearing applications. The reinforcing fibers, like carbon, glass, or aramid, provide superior strength-to-weight ratios compared to materials like steel or aluminum. 2. Lightness: FRP profiles are significantly lighter than metals, leading to reduced costs for transportation and installation. Their low weight also makes them easier to handle and manipulate during construction or manufacturing processes. 3. Resistance to Corrosion: Unlike metals, FRP profiles are inherently resistant to corrosion. They do not rust or degrade when exposed to harsh environments, including moisture, chemicals, or UV radiation. This makes them ideal for marine, chemical, and infrastructure industries. 4. Dimensional Stability: FRP profiles maintain their shape and size even under extreme temperature variations. They have minimal rates of thermal expansion and contraction, ensuring long-term structural integrity. 5. Electrical Insulation: FRP profiles are non-conductive and possess excellent electrical insulation properties. This is crucial in applications where electrical conductivity must be avoided, such as near power lines or in electrical enclosures. 6. Versatile Design: FRP pultrusion profiles can be manufactured in various complex shapes and sizes, allowing for customized designs to meet specific requirements. They can be easily molded or formed during the manufacturing process, making them adaptable to diverse project needs. 7. Impact Resistance: FRP profiles have good impact resistance, absorbing and dispersing energy when subjected to mechanical loads. This ensures durability and structural integrity, making them suitable for construction, transportation, or sporting equipment. Overall, the mechanical properties of FRP pultrusion profiles make them an appealing alternative to traditional materials in a wide range of industries. They offer strength, durability, and corrosion resistance while being lightweight and easy to work with.

Send your message to us

FRP Pultrusion Profiles - High Strength, Corrosion Resistant, and Fire Resistant for Platform with Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords