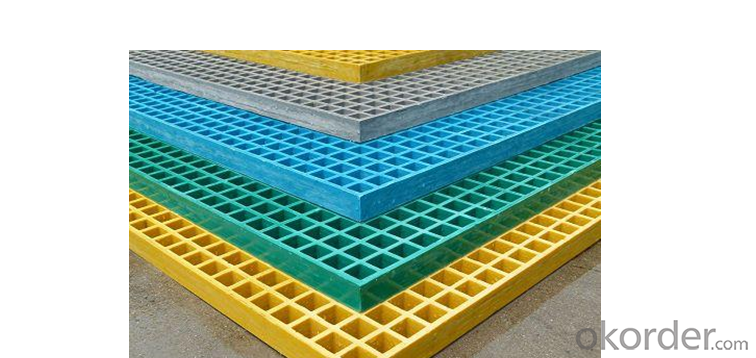

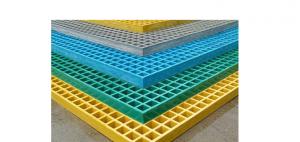

FRP Pultrusion Profiles - High Strength, Corrosion Resistant and Fire Resistant Gratings with Modern Shape & Great Color

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

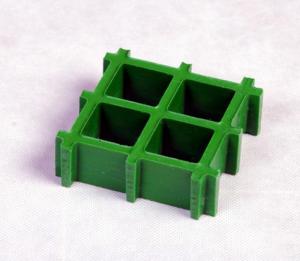

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

- Light Weight & High Strength

- Electrical Insulating

Aging Resistance

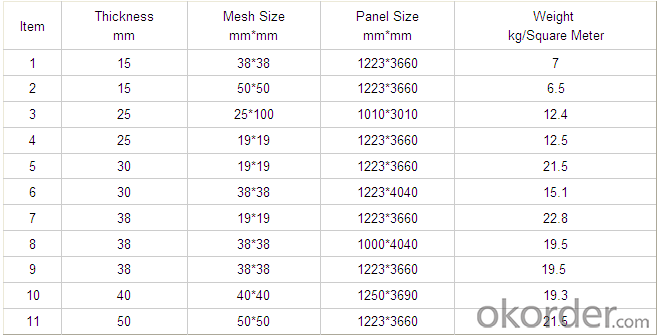

Specification

Advantage

coated with prevent aging layer

excellent insulating performance

no maintenance

Application

Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

Corrosive chemical industry equipment around the fence

All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

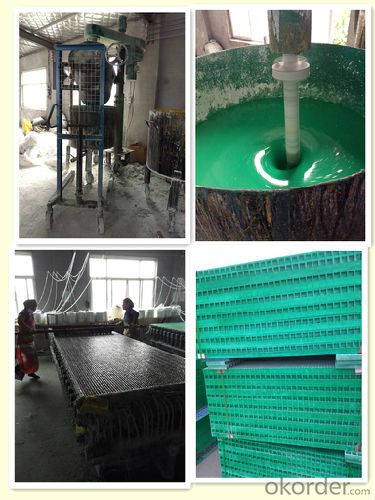

PROCESS

FACTORY

- Q: Can FRP pultrusion profiles be used in the construction of water treatment plants?

- Water treatment plants can utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles possess several advantages that render them suitable for this purpose. To begin with, FRP pultrusion profiles exhibit resistance to corrosion. Water treatment plants encounter various corrosive substances, such as chemicals and moisture. Traditional materials like steel and concrete can degrade over time due to corrosion, resulting in maintenance complications and potential structural failures. Nevertheless, FRP pultrusion profiles possess a high resistance to corrosion, ensuring prolonged durability and reduced maintenance expenses. Furthermore, FRP pultrusion profiles are lightweight and possess high strength-to-weight ratios. This characteristic facilitates easy handling and transportation while maintaining structural integrity. Water treatment plants often necessitate structural components that can endure heavy loads and support equipment. FRP pultrusion profiles supply the required strength without adding excessive weight, making them an ideal choice for such applications. Additionally, FRP pultrusion profiles are non-conductive and possess exceptional electrical insulation properties. This attribute proves critical in water treatment plants where electrical apparatus and wiring are present. The non-conductive nature of FRP aids in preventing electrical hazards and guarantees safe operation. Moreover, FRP pultrusion profiles can be customized to fulfill specific design requirements. They can be manufactured in various shapes and sizes, allowing for design and construction flexibility. This adaptability renders FRP pultrusion profiles appropriate for a wide array of applications within water treatment plants, including structural supports, walkways, handrails, and equipment enclosures. In conclusion, FRP pultrusion profiles represent an exceptional option for the construction of water treatment plants due to their corrosion resistance, lightweight yet robust nature, electrical insulation properties, and customization possibilities. They provide long-lasting durability, reduced maintenance costs, and enhanced safety, thereby constituting a reliable and efficient solution for this critical infrastructure.

- Q: How do FRP pultrusion profiles perform in electrical grounding systems?

- FRP pultrusion profiles have demonstrated promising performance in electrical grounding systems, showcasing their potential. These profiles consist of a combination of fibers, such as glass or carbon, and a polymer resin matrix. This unique composition provides them with exceptional attributes, including high strength, durability, and resistance to corrosion. One noteworthy advantage of FRP pultrusion profiles in electrical grounding systems lies in their remarkable electrical insulation properties. Unlike metals, which conduct electricity, FRP profiles possess a significantly high resistance to electrical current. This aspect renders them ideal for applications where electrical isolation is paramount. By doing so, they effectively mitigate the risks associated with electrical shock hazards and diminish the potential for short circuits. Furthermore, FRP pultrusion profiles offer superior mechanical strength while remaining lightweight. Consequently, they are easy to handle and install, leading to reduced labor costs and time consumption. Additionally, these profiles exhibit resistance against UV radiation, chemicals, and moisture, ensuring their long-term performance and durability across various environmental conditions. Another advantageous attribute of FRP pultrusion profiles pertains to their corrosion resistance. Unlike metals, which are susceptible to rust and deterioration over time, FRP profiles remain immune to corrosion. This quality renders them highly suitable for deployment in harsh or corrosive environments, guaranteeing the longevity and reliability of the electrical grounding system. Moreover, FRP pultrusion profiles exhibit non-magnetic properties, presenting an advantage in situations where minimizing or eliminating magnetic interference is crucial. This characteristic effectively prevents any disturbances to sensitive electrical equipment, thereby ensuring accurate electrical measurements. In conclusion, FRP pultrusion profiles offer a multitude of advantages in electrical grounding systems. Their exceptional electrical insulation properties, impressive mechanical strength, corrosion resistance, lightweight nature, and non-magnetic characteristics make them a reliable and efficient choice for guaranteeing the safety and reliability of electrical grounding.

- Q: Can FRP pultrusion profiles be used in the construction of train or subway platforms?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of train or subway platforms. FRP pultrusion profiles are made of a combination of reinforced fibers and a polymer resin matrix, which gives them high strength and durability. These profiles are lightweight, corrosion-resistant, and have excellent mechanical properties, making them suitable for various applications in the construction industry. When it comes to train or subway platforms, FRP pultrusion profiles can be used for various structural components such as handrails, guardrails, gratings, and decking systems. These profiles provide a non-conductive and non-magnetic solution, which is essential in railway environments to prevent interference with electrical and signaling systems. Furthermore, FRP pultrusion profiles offer a high level of customization, allowing them to be tailored to specific project requirements. They can be manufactured in various shapes, sizes, and colors to meet the aesthetic and functional needs of train or subway platforms. Moreover, FRP pultrusion profiles have excellent resistance to environmental factors such as moisture, chemicals, and UV radiation. This resistance ensures that the profiles remain durable and maintain their structural integrity over time, even in harsh and corrosive conditions commonly found in railway environments. Overall, FRP pultrusion profiles are a reliable and cost-effective choice for the construction of train or subway platforms. They provide numerous advantages including strength, durability, customization options, and resistance to environmental factors, making them a suitable alternative to traditional materials in these applications.

- Q: What is the cost of FRP pultrusion profiles compared to other materials?

- The price of FRP pultrusion profiles can vary based on several factors, including the specific application, size, design complexity, and quantity needed. However, in general, FRP pultrusion profiles are often more cost-effective than many traditional materials. Compared to materials like steel, aluminum, or wood, FRP pultrusion profiles generally offer a lower overall cost, particularly when considering long-term savings. While the initial cost of FRP pultrusion profiles may be slightly higher than some traditional materials, the advantages it provides can outweigh the price difference. FRP pultrusion profiles are renowned for their lightweight nature, high strength-to-weight ratio, resistance to corrosion, and durability. These characteristics help reduce transportation expenses, installation costs, and maintenance needs. Furthermore, the long lifespan of FRP profiles ensures minimal repair or replacement costs over time. Additionally, the manufacturing process of FRP pultrusion profiles allows for precise customization, eliminating the necessity for extra machining or fabrication, which can further reduce expenses. Incorporating design features like integral stiffeners, brackets, and fastening points during the pultrusion process eliminates the need for additional assembly steps, ultimately saving time and money. It is important to acknowledge that although FRP pultrusion profiles may have a higher initial cost compared to some materials, their overall cost-effectiveness and long-term benefits make them a favorable choice in many applications. When evaluating the cost of FRP pultrusion profiles in contrast to other materials, one should consider the specific requirements and considerations of each project.

- Q: Can FRP pultrusion profiles be used in the agricultural and farming industry?

- Yes, FRP pultrusion profiles can certainly be used in the agricultural and farming industry. FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their high strength, durability, and resistance to corrosion, making them ideal for outdoor and harsh environments such as those found in the agricultural and farming industry. These profiles can be used for various applications in agriculture and farming, including: 1. Fencing and enclosures: FRP pultrusion profiles can be used to create sturdy and long-lasting fences, gates, and enclosures for livestock and crop protection. The profiles are resistant to rot, rust, and insect damage, providing a reliable barrier for animals and crops. 2. Structural components: FRP pultrusion profiles can be used as structural components in agricultural buildings, sheds, and greenhouses. Their high strength-to-weight ratio allows for the construction of lightweight and durable structures that can withstand extreme weather conditions. 3. Irrigation systems: FRP pultrusion profiles can be used in the construction of irrigation systems, such as pipes, channels, and culverts. These profiles are non-corrosive and have a smooth interior surface, reducing friction and improving water flow efficiency. 4. Equipment support and framing: FRP pultrusion profiles can be used to provide support and framing for various agricultural equipment, such as conveyors, platforms, and machinery. Their high strength and stiffness make them suitable for heavy-duty applications. 5. Animal housing and equipment: FRP pultrusion profiles can be used to construct animal housing and equipment, such as pens, stalls, and feeding troughs. These profiles are resistant to chemicals, moisture, and UV radiation, ensuring a long lifespan and low maintenance requirements. In summary, FRP pultrusion profiles can be successfully utilized in the agricultural and farming industry due to their excellent mechanical properties, resistance to environmental factors, and versatility in various applications.

- Q: Are FRP pultrusion profiles resistant to chemicals used in food packaging?

- Yes, FRP pultrusion profiles are generally resistant to the chemicals commonly used in food packaging. The combination of fiberglass reinforcement and resin matrix used in FRP profiles provides excellent chemical resistance, making them a suitable choice for applications involving contact with food packaging chemicals. However, it is always recommended to consult with the manufacturer or supplier to ensure specific compatibility with the chemicals involved.

- Q: How do FRP pultrusion profiles perform in high humidity environments?

- FRP pultrusion profiles perform exceptionally well in high humidity environments. The fiberglass reinforcement in the profiles provides excellent resistance to moisture absorption, preventing any adverse effects on their structural integrity. This makes them highly durable and suitable for long-term use in humid conditions without any significant degradation or damage.

- Q: Can FRP pultrusion profiles be used in the oil and gas industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the oil and gas industry. FRP pultrusion profiles offer several advantages that make them suitable for applications in this industry. Firstly, FRP pultrusion profiles are corrosion-resistant. They do not rust, corrode, or degrade when exposed to harsh environments, such as saltwater, chemicals, and extreme temperatures. This makes them ideal for use in offshore platforms, pipelines, and other oil and gas facilities where corrosion can be a significant issue. Secondly, FRP pultrusion profiles have high strength-to-weight ratio. They are lightweight yet extremely strong, allowing for efficient installation, transportation, and handling. This is particularly beneficial in the oil and gas industry, where weight reduction is a crucial factor in improving operational efficiency and reducing costs. Thirdly, FRP pultrusion profiles can be customized to meet specific requirements. They can be manufactured in various shapes, sizes, and configurations, making them versatile for different applications in the oil and gas industry. Whether it is for structural supports, grating, handrails, or other components, FRP pultrusion profiles can be tailored to fit the specific needs of each project. Furthermore, FRP pultrusion profiles offer excellent electrical insulation properties. This is important in the oil and gas industry, where electrical safety is paramount. FRP profiles can provide insulation and prevent electrical conductivity, reducing the risk of accidents and ensuring the safety of personnel and equipment. Overall, FRP pultrusion profiles have proven to be reliable, durable, and cost-effective solutions for various applications in the oil and gas industry. Their corrosion resistance, high strength-to-weight ratio, customization capabilities, and electrical insulation properties make them an attractive choice for this demanding industry.

- Q: Can FRP pultrusion profiles be used in wastewater treatment facilities?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in wastewater treatment facilities. FRP pultrusion profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and durability, which make them suitable for use in harsh environments like wastewater treatment facilities. In wastewater treatment facilities, there are various applications where FRP pultrusion profiles can be used. These include but are not limited to walkways, handrails, ladders, grating, and structural supports. The corrosion resistance of FRP makes it ideal for use in areas exposed to moisture and chemicals present in wastewater. Furthermore, FRP profiles are lightweight, which simplifies installation and reduces the load on supporting structures. The durability of FRP pultrusion profiles ensures long-term performance, even in aggressive environments. They have a high resistance to chemical attack, UV radiation, and bacterial growth, making them suitable for wastewater treatment applications. Additionally, FRP profiles can be designed to meet specific load requirements and can be easily fabricated to fit various shapes and sizes. Moreover, FRP pultrusion profiles offer excellent electrical insulation properties, which can be advantageous in wastewater treatment facilities where electrical safety is a concern. In summary, FRP pultrusion profiles can be effectively used in wastewater treatment facilities due to their corrosion resistance, durability, lightweight nature, and versatility in design and fabrication. These profiles can provide long-lasting solutions for various applications within these facilities, ensuring operational efficiency and minimizing maintenance requirements.

- Q: Can FRP pultrusion profiles be used in the construction of offshore platforms?

- Yes, FRP pultrusion profiles can be used in the construction of offshore platforms. FRP, or fiber-reinforced polymer, offers excellent corrosion resistance, high strength-to-weight ratio, and durability, making it suitable for the harsh marine environment. These profiles can be customized to meet the specific requirements of offshore platforms, providing structural support and stability while minimizing maintenance needs.

Send your message to us

FRP Pultrusion Profiles - High Strength, Corrosion Resistant and Fire Resistant Gratings with Modern Shape & Great Color

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords