Fiberglass Grating Panel Sheet For Various Usage

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Descprition for FRP Grating

With dozens of years' hard works, we now have ability to produce a whole series of FRP products, these include: FRP Molded Grating; FRP Pultruded Grating; Phenolic Molded & Pultruded Grating; FRP Pultruded Structural Profiles; FRP Pultruded Handrails; FRP Pultruded Ladders; FRP Flat Sheet; FRP Decking; FRP Stair tread & Nosing and many customs FRP products. The company has been becoming a most reliable FRP products manufacturer with its stable quality, large productivity & prompt delivery, advanced production systems, rich types. Now our products sell well all over the world, especially in North America, European Areas, South Asia and Middle East.

FRP Grating Features

Corrosion and Chemical resistant;Slip-resistant ;High strength-to-weight ratio;Ergonomic ;Low maintenance ;Fire retardant ;Easily fabricated and installed

Other Positive Features or Advantages

1.Electrically and thermally non-conductive

2.Ultra-violet resistant

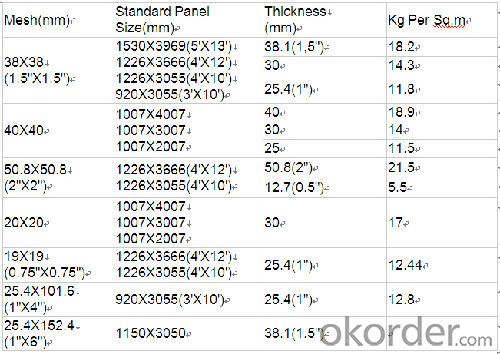

3.Provided in a number of grating thickness and panel sizes with many types of mesh size

4.Offers bi-directional strength characteristic

5.Impact resistance

6.Electronically transparent

Specification

FAQ

1.Which country do you mainly export to?

A: Our products are very popular in Mid East, India, South East Asia, Latin America, Africa.

2.Q: What’s the advantage of you compared with other suppliers experienced in foreign trade?

A: We have been specialized in FRP products for over decades years and approved by many domestic companies. Except for our quality and price, we’re also able to give you the best service.

3.Q:Can you provide some samples?

A: Yes, of course. We will send you samples for your confirmation before you place firm orders.

- Q: How do FRP pultrusion profiles compare to fiberglass reinforced panels (FRP)?

- FRP pultrusion profiles and fiberglass reinforced panels (FRP) are both commonly used materials in various industries due to their high strength and durability. However, there are some notable differences when comparing these two FRP products. 1. Manufacturing Process: FRP pultrusion profiles are created through a continuous pultrusion process, where fibers are pulled through a resin bath and then cured using heat or ultraviolet light. This results in a solid and uniform profile with consistent mechanical properties. On the other hand, fiberglass reinforced panels are made by combining layers of fiberglass mat and resin, which are typically molded or pressed together. This process can sometimes result in variations in thickness and mechanical properties across the panel. 2. Structural Strength: FRP pultrusion profiles are known for their exceptional strength-to-weight ratio. The continuous fiber reinforcement used in pultrusion provides high stiffness and load-bearing capacity, making them suitable for structural applications. Conversely, while fiberglass reinforced panels are also strong, they may not possess the same level of structural integrity as pultrusion profiles due to the potential for variations in resin content and fiber distribution. 3. Design Flexibility: FRP pultrusion profiles offer greater design flexibility compared to fiberglass reinforced panels. The pultrusion process allows for the incorporation of various shapes and configurations, such as I-beams, angles, tubes, and custom profiles. This versatility enables engineers to tailor the profiles to specific project requirements. In contrast, fiberglass reinforced panels are typically limited to flat or slightly curved surfaces and do not provide the same level of customization. 4. Surface Finish: FRP pultrusion profiles often have a smooth and consistent surface finish due to the pultrusion process. This makes them more aesthetically appealing and suitable for applications where appearance is important. Fiberglass reinforced panels, on the other hand, may have a textured or uneven surface, which can impact their visual appeal in certain applications. 5. Cost: When comparing costs, FRP pultrusion profiles are generally more expensive than fiberglass reinforced panels. The pultrusion process requires specialized equipment and has higher manufacturing costs. Fiberglass reinforced panels, on the other hand, have lower production costs due to their simpler manufacturing process. However, it is important to consider the specific application requirements and long-term performance when evaluating the cost-effectiveness of these materials. In summary, FRP pultrusion profiles and fiberglass reinforced panels have their own unique characteristics and advantages. The choice between the two will depend on factors such as structural requirements, design flexibility, surface finish, and cost considerations.

- Q: Can FRP pultrusion profiles be used in the production of electrical insulators?

- Yes, FRP pultrusion profiles can be used in the production of electrical insulators. FRP (Fiber Reinforced Polymer) offers excellent electrical insulation properties, high strength, and corrosion resistance, making it suitable for insulating applications in various industries, including electrical. The pultrusion process enables the production of customized profiles with consistent dimensions and properties, further enhancing their suitability for electrical insulator manufacturing.

- Q: How do FRP pultrusion profiles perform in extreme temperatures?

- FRP pultrusion profiles are known for their excellent performance in extreme temperatures. Due to their unique composition of fiberglass and resin matrix, they are highly resistant to thermal expansion and contraction. This means that even in extremely cold or hot environments, FRP profiles maintain their structural integrity without warping or deforming. In high-temperature conditions, FRP pultrusion profiles exhibit remarkable dimensional stability and do not soften or melt like some other materials. They have a high glass transition temperature, which allows them to withstand even the most extreme heat without losing their strength or shape. This makes FRP profiles suitable for applications such as furnace components, exhaust systems, and industrial ovens. On the other hand, in extremely cold temperatures, FRP pultrusion profiles remain tough and durable. They do not become brittle or prone to cracking like traditional materials such as metal or concrete. This makes them suitable for use in cold storage facilities, refrigerated trucks, and other low-temperature environments. Furthermore, FRP pultrusion profiles have excellent resistance to chemical corrosion. They are not affected by exposure to various chemicals or solvents, making them suitable for use in harsh chemical processing environments. This resistance to chemical corrosion also extends to extreme temperatures, further enhancing their performance in such conditions. Overall, FRP pultrusion profiles have proven to be reliable and versatile materials in extreme temperature environments. Their ability to maintain structural integrity, dimensional stability, and resistance to chemical corrosion make them a preferred choice for various industries and applications where temperature extremes are a concern.

- Q: What are pultrusion materials used for?

- Plastic pultrusion materials are used for drawing and blowing tubes

- Q: Are FRP pultrusion profiles resistant to caustic soda?

- Yes, FRP pultrusion profiles are generally resistant to caustic soda. The corrosion-resistant properties of FRP make it suitable for use in environments that involve caustic soda or other aggressive chemicals. However, it is always recommended to evaluate the specific conditions and concentration of the caustic soda to ensure the compatibility of FRP profiles.

- Q: Are FRP pultrusion profiles resistant to saltwater corrosion?

- Yes, FRP pultrusion profiles are highly resistant to saltwater corrosion. The combination of their fiberglass reinforcement and the corrosion-resistant resin matrix used in their manufacturing make them ideal for applications in marine environments. They are capable of withstanding prolonged exposure to saltwater without degradation or loss of structural integrity.

- Q: Can FRP pultrusion profiles be used in electrical insulation applications?

- Yes, FRP pultrusion profiles can be used in electrical insulation applications. FRP (Fiber Reinforced Polymer) materials have excellent electrical insulation properties, making them suitable for a wide range of electrical applications. The pultrusion process ensures that the profiles have uniform insulation properties and high strength, making them ideal for use in electrical insulation applications.

- Q: Can FRP pultrusion profiles be used in the construction of water slides?

- Yes, FRP pultrusion profiles can be used in the construction of water slides. FRP, or fiberglass reinforced plastic, offers excellent strength, durability, and corrosion resistance, making it a suitable material for water slide components. The pultrusion process allows for the production of customized profiles with specific shapes and dimensions, ensuring compatibility with water slide design requirements. Additionally, FRP's lightweight nature simplifies installation and maintenance while providing a safe and enjoyable experience for water slide users.

- Q: Can FRP pultrusion profiles be used in the construction of chemical processing equipment?

- FRP pultrusion profiles have the capability to be utilized in the construction of chemical processing equipment. These profiles possess multiple advantages that render them suitable for such applications. To begin with, FRP pultrusion profiles exhibit a high resistance to corrosion, making them an ideal choice for chemical environments where exposure to corrosive substances is frequent. Unlike conventional materials like steel, FRP pultrusion profiles do not rust or corrode, resulting in an extended service life and reduced maintenance costs. Moreover, FRP pultrusion profiles are both lightweight and strong, providing exceptional structural integrity and load-bearing capacity. This is particularly crucial in chemical processing equipment, where the materials employed must endure high pressures and temperatures. The strength of FRP pultrusion profiles permits the construction of sturdy and durable equipment. Furthermore, FRP pultrusion profiles offer flexibility in design, allowing for customization of shapes and sizes to fulfill specific requirements. This permits the construction of intricate chemical processing equipment with complex designs that are not easily achievable using traditional materials. Additionally, FRP pultrusion profiles possess excellent electrical insulation properties, which can be advantageous in chemical processing equipment where minimizing electrical conductivity is necessary to prevent unwanted reactions or hazards. In conclusion, FRP pultrusion profiles are a dependable and cost-effective option for constructing chemical processing equipment. Their corrosion resistance, strength, design flexibility, and electrical insulation properties make them suitable for a wide range of applications in the chemical industry.

- Q: Can FRP pultrusion profiles be used in the construction of swimming pool enclosures?

- Swimming pool enclosures can make use of FRP pultrusion profiles, which are known for their excellent strength-to-weight ratio, corrosion resistance, and durability. This makes them an ideal choice for outdoor applications like swimming pool enclosures. To manufacture FRP pultrusion profiles, fiberglass rovings are pulled through a resin bath and then through a heated die. This results in a continuous profile of uniform shape and strength. This manufacturing process ensures that the profiles are strong, stiff, and lightweight, making them easy to handle and install. In the construction of swimming pool enclosures, FRP pultrusion profiles can be utilized for various structural elements such as beams, columns, trusses, and panels. These profiles provide the necessary strength and support, while also offering resistance to corrosion, moisture, and UV radiation, which are common challenges in a swimming pool environment. Furthermore, FRP pultrusion profiles can be customized to meet specific design requirements, allowing for flexibility in creating unique and aesthetically pleasing swimming pool enclosures. They can be fabricated in different shapes, sizes, and colors, enabling the desired architectural look and feel. Overall, FRP pultrusion profiles offer a reliable and long-lasting solution for constructing swimming pool enclosures. They provide the necessary strength, durability, and resistance to environmental factors. Additionally, their lightweight nature simplifies handling and installation, ultimately reducing construction time and costs.

Send your message to us

Fiberglass Grating Panel Sheet For Various Usage

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords