FRP Pultrusion Profiles - Corrosion Resistant and Fire Resistant FRP Grating

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

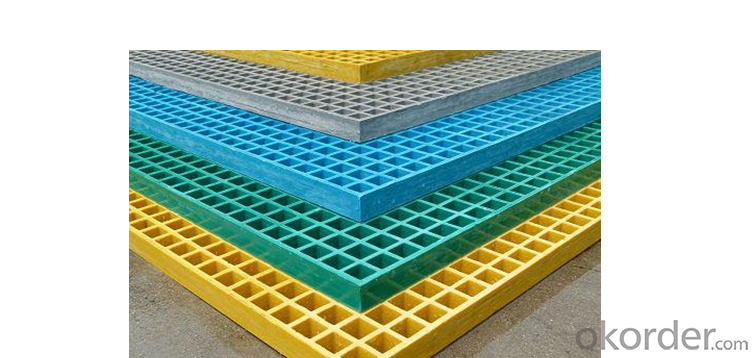

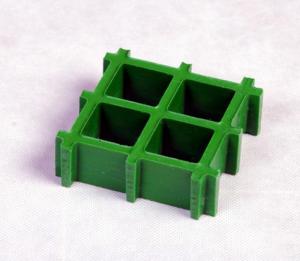

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

Fire Resistance

Light Weight & High Strength

Safety & Anti-slip

Electrical Insulating

Aging Resistance

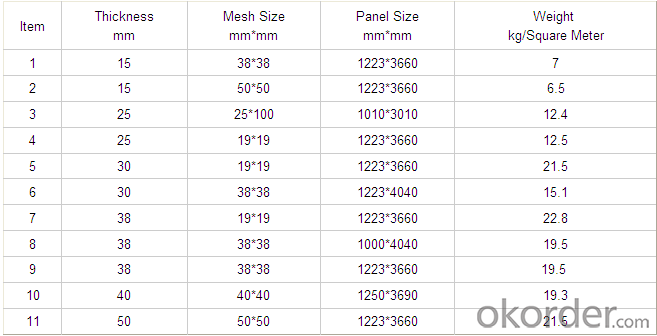

Specification

Advantage

coated with prevent aging layer

excellent insulating performance

no maintenance

high strength

long service life

easy installation

Application

Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

Pool railings in sewage treatment industry

Corrosive chemical industry equipment around the fence

All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

3. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

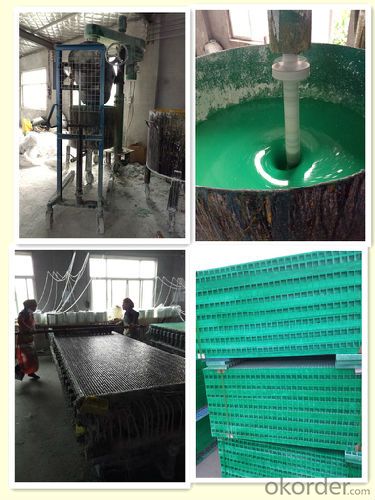

FACTORY

- Q: Are FRP pultrusion profiles resistant to chemicals used in food packaging?

- Yes, FRP pultrusion profiles are generally resistant to the chemicals commonly used in food packaging. The combination of fiberglass reinforcement and resin matrix used in FRP profiles provides excellent chemical resistance, making them a suitable choice for applications involving contact with food packaging chemicals. However, it is always recommended to consult with the manufacturer or supplier to ensure specific compatibility with the chemicals involved.

- Q: What are pultrusion materials used for?

- Various sections of Glass Fiber Reinforced Plastic Pultruded sections can be produced with different sections of the die. The profile has the characteristics of high strength, corrosion resistance and light weight

- Q: Can FRP pultrusion profiles be used in the construction of amusement park rides?

- Yes, FRP pultrusion profiles can be used in the construction of amusement park rides. FRP (Fiber Reinforced Polymer) pultrusion profiles offer high strength-to-weight ratio, corrosion resistance, and durability, making them suitable for various applications in amusement park rides. These profiles can be used for structural components, such as supports, frames, and beams, as well as for aesthetic elements like facades or decorative structures. Additionally, FRP pultrusion profiles can be customized to meet specific design requirements, making them a versatile choice for constructing amusement park rides.

- Q: Can FRP pultrusion profiles be used in the construction of theme park rides?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of theme park rides. FRP pultrusion profiles offer several advantages that make them suitable for this application. Firstly, FRP pultrusion profiles are lightweight yet strong, making them ideal for constructing ride structures that need to withstand dynamic loads and forces. Their high strength-to-weight ratio allows for the creation of large, complex structures that can support the weight of riders and withstand the forces generated during operation. Additionally, FRP pultrusion profiles are corrosion-resistant, which is crucial for theme park rides that are often exposed to outdoor environments, including moisture, chemicals, and UV radiation. This corrosion resistance ensures that the ride structures remain durable and safe over their lifespan, reducing the need for costly maintenance and repairs. Another advantage of FRP pultrusion profiles is their design flexibility. They can be easily molded into various shapes and sizes to meet the specific requirements of theme park ride designs. This versatility allows for the creation of unique and visually appealing ride structures that enhance the overall experience for park visitors. Furthermore, FRP pultrusion profiles offer excellent electrical insulation properties, which can be essential for rides that involve electrical components or systems. This insulation helps to minimize the risk of electrical hazards and ensures the safety of riders and operators. In conclusion, FRP pultrusion profiles are well-suited for the construction of theme park rides due to their lightweight, high strength, corrosion resistance, design flexibility, and electrical insulation properties. These profiles can contribute to the development of safe, durable, and visually appealing ride structures that enhance the enjoyment and excitement of theme park visitors.

- Q: What are the main uses of pultruded glass fiber reinforced plastic extrusions?

- Spend entertainment mall, this is a potential market, the development of use: fishing rod, curtain rod, umbrella frame, flagpole, stuff handle, lamp, railings, handrails and staircases, radio antenna, marinas, garden tools and accessories.

- Q: Are FRP pultrusion profiles resistant to oil and grease?

- FRP pultrusion profiles are widely recognized for their exceptional ability to withstand oil and grease. The combination of fibers, typically glass or carbon, with a polymer resin matrix creates a material that is naturally resistant to numerous chemicals, including oil and grease. This resistance can be attributed to the non-reactive nature of the polymer resin, which prevents oil or grease from infiltrating the material and causing harm. Moreover, the pultrusion manufacturing process further enhances the profiles' resistance to oil and grease. In this process, the fibers are soaked in the resin and then drawn through a heated die, where the resin solidifies. This results in a sturdy, uniform material with a compact surface that is less porous and more capable of resisting chemical penetration. It is important to acknowledge that the specific resistance of FRP pultrusion profiles to oil and grease can vary depending on the resin used and the conditions of the application. In certain instances, specialized resin formulations can be employed to augment the profiles' oil and grease resistance, ensuring suitability for even the most demanding environments. Overall, FRP pultrusion profiles are widely regarded as highly resistant to oil and grease, making them an exceptional choice for applications exposed to these substances. However, it is always advisable to consult with the manufacturer or supplier to confirm that the specific FRP profile being utilized is suitable for the intended application and chemical exposure.

- Q: Are FRP pultrusion profiles resistant to chemicals used in food processing?

- The resistance of FRP pultrusion profiles to chemicals commonly used in food processing is generally high. FRP, a type of fiberglass reinforced plastic, is well-known for its exceptional chemical resistance, making it a suitable material for various industrial uses, including the food processing industry. These profiles are made by combining resins and fiberglass reinforcements, which give them inherent resistance to a wide array of chemicals. Acids, alkalis, solvents, and many other chemicals often found in food processing environments are typically resisted by FRP pultrusion profiles. This resistance ensures that the profiles will not corrode, degrade, or react with these chemicals, thus maintaining their structural integrity over time. Consequently, FRP pultrusion profiles are regarded as a dependable choice for equipment, structures, and components used in food processing facilities. However, it is important to note that the specific chemical resistance of FRP pultrusion profiles may vary depending on the resin system used in their production. Different resins offer different levels of resistance to specific chemicals. Therefore, it is crucial to carefully select the appropriate resin formulation that matches the specific chemical environment in the food processing industry. To ensure the compatibility of FRP pultrusion profiles with the chemicals commonly used in food processing, it is advisable to consult with the manufacturer or supplier. They can provide detailed information regarding the chemical resistance properties of their FRP profiles and assist in selecting the most suitable materials for the specific application. Additionally, proper maintenance and regular cleaning practices should be implemented to ensure the longevity and sustained chemical resistance of FRP pultrusion profiles in food processing environments.

- Q: Are FRP pultrusion profiles resistant to moisture absorption?

- FRP pultrusion profiles possess remarkable resistance to moisture absorption, primarily due to the composition of the materials used in their construction. These profiles typically consist of a combination of fiberglass and resin, wherein fiberglass is naturally non-porous and impervious to moisture, while the resin is specifically designed to repel moisture. The moisture resistance of FRP profiles is further enhanced by the pultrusion manufacturing process. This process involves pulling the fiberglass and resin through a heated die, ensuring thorough impregnation of the fibers with resin and creating a dense and solid structure. Consequently, the resulting product exhibits exceptional resistance to water penetration and moisture absorption. Additionally, the moisture resistance of FRP pultrusion profiles can be augmented through the application of protective coatings or surface treatments, such as gel coats or UV-resistant finishes. These coatings provide an extra layer of defense against moisture ingress. The superior moisture resistance of FRP pultrusion profiles makes them an ideal choice for applications that involve exposure to water or high humidity, such as marine environments, wastewater treatment plants, or outdoor structures. By preventing issues like rot, rust, or degradation commonly associated with materials like wood or metal, these profiles offer a reliable and durable solution that can endure moisture exposure without compromising their structural integrity or performance.

- Q: Are FRP pultrusion profiles resistant to sulfuric acid?

- Yes, FRP pultrusion profiles are generally resistant to sulfuric acid due to the corrosion-resistant properties of the fiber-reinforced plastic material. However, it is important to consider the concentration and temperature of the sulfuric acid, as extreme conditions can potentially affect the resistance of FRP profiles.

- Q: Are FRP pultrusion profiles suitable for the manufacturing of chemical reactors?

- Yes, FRP pultrusion profiles are suitable for the manufacturing of chemical reactors. FRP (Fiber Reinforced Polymer) pultrusion profiles offer excellent resistance to corrosion, high strength-to-weight ratio, and dimensional stability, making them ideal for use in chemical reactors. Additionally, FRP materials can withstand a wide range of chemical environments and temperatures, making them a reliable choice for this application.

Send your message to us

FRP Pultrusion Profiles - Corrosion Resistant and Fire Resistant FRP Grating

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords