FRP Pultrusion Profiles - High Strength, Corrosion Resistant and Fire Resistant Fiberglass Grating for Platform, Walkway, Trench Cover

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

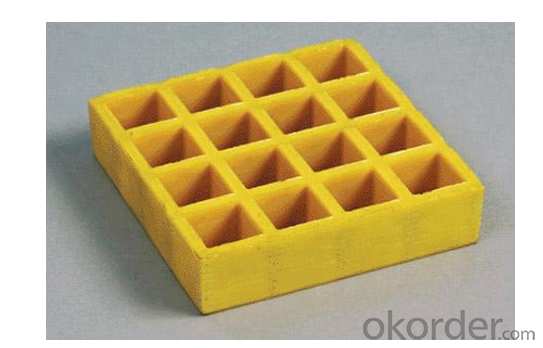

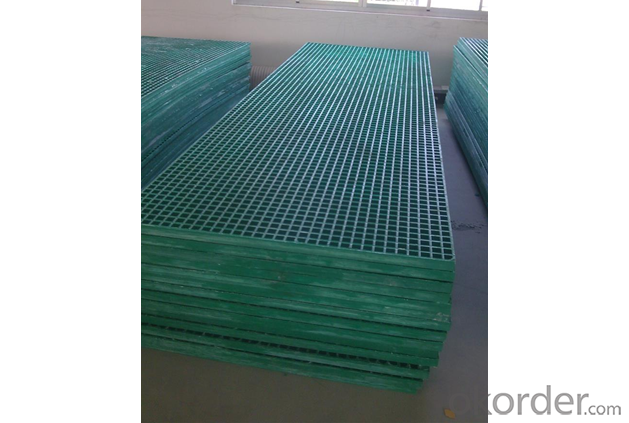

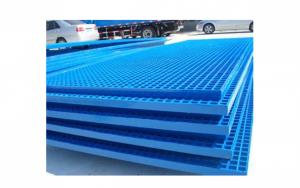

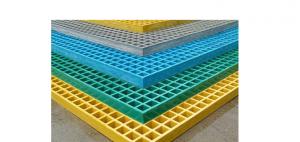

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

Fire Resistance

Light Weight & High Strength

Safety & Anti-slip

Electrical Insulating

Aging Resistance

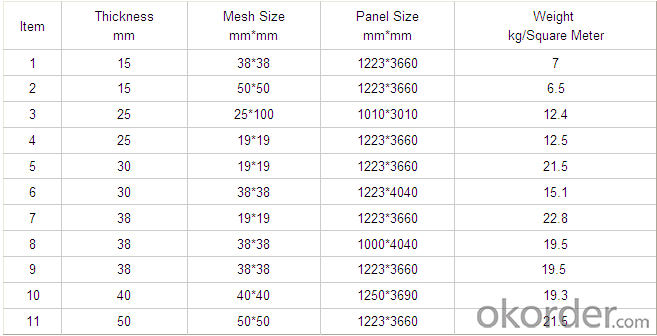

Specification

Advantage

coated with prevent aging layer

excellent insulating performance

no maintenance

high strength

long service life

easy installation

Application

In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

Pool railings in sewage treatment industry

Corrosive chemical industry equipment around the fence

All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

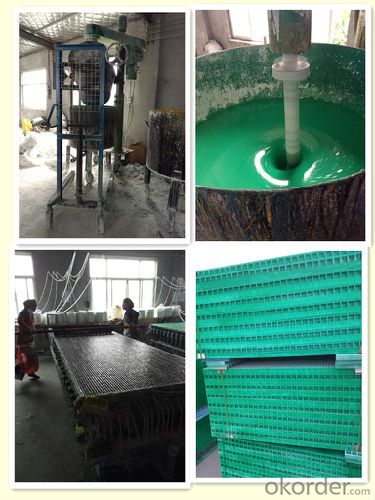

FACTORY

- Q: What are pultrusion materials used for?

- Plastic pultrusion materials are used for drawing and blowing tubes

- Q: How do FRP pultrusion profiles compare to traditional materials, such as steel or aluminum?

- Compared to traditional materials like steel or aluminum, FRP pultrusion profiles present several benefits. Firstly, they are significantly lighter in weight, which facilitates handling and transportation. This advantage is particularly valuable in industries where weight reduction is crucial, such as aerospace or automotive. Furthermore, FRP pultrusion profiles possess high corrosion resistance, unlike steel, which is prone to rust, and aluminum, which can corrode in specific environments. This resistance to corrosion makes FRP profiles ideal for use in harsh or corrosive surroundings, such as chemical plants or coastal areas. Another advantage of FRP pultrusion profiles is their exceptional strength-to-weight ratio. Despite being lightweight, they exhibit remarkable strength and stiffness, often surpassing steel and aluminum. This strength allows for the creation of structurally efficient components, reducing material and installation costs. Additionally, FRP profiles are non-conductive, providing inherent insulation properties. This characteristic makes them suitable for applications where electrical conductivity is undesirable, such as electrical cabinets or offshore platforms. In terms of thermal conductivity, FRP pultrusion profiles have low thermal conductivity compared to metals. This feature improves insulation and minimizes heat transfer, making them suitable for applications that require temperature control or insulation, such as refrigeration or thermal insulation systems. Lastly, FRP pultrusion profiles offer high customizability. They can be easily molded into intricate shapes and sizes, allowing for design flexibility and meeting specific project requirements. This versatility makes FRP profiles suitable for a wide range of applications, including construction, infrastructure, and industrial sectors. Overall, FRP pultrusion profiles provide numerous advantages over traditional materials like steel or aluminum, including lighter weight, corrosion resistance, high strength-to-weight ratio, electrical insulation, low thermal conductivity, and design flexibility. These benefits make FRP profiles the preferred choice in various industries, providing cost-effective and reliable solutions.

- Q: How do FRP pultrusion profiles handle torsion loads?

- FRP pultrusion profiles are known for their excellent mechanical properties and high strength-to-weight ratio, making them an ideal choice for handling torsion loads. When subjected to torsion, these profiles are designed to withstand twisting forces and maintain their structural integrity. The key to their ability to handle torsion loads lies in their construction. FRP pultrusion profiles are manufactured by pulling reinforcing fibers, such as fiberglass, through a resin bath and then through a heated die. This process aligns the fibers in the direction of the load, providing exceptional strength and stiffness. In the case of torsion loads, the aligned fibers in the profile's cross-section resist the twisting force by distributing it along the length of the profile. This distribution of force helps prevent localized stress concentrations, reducing the risk of deformation or failure. Additionally, the resin matrix surrounding the fibers acts as a binding agent, holding the fibers together and providing protection against environmental factors such as moisture, chemicals, and UV radiation. This ensures the long-term durability and stability of the profile under torsion loads. Furthermore, FRP pultrusion profiles can be designed with specific cross-sectional shapes and dimensions to enhance their torsional strength. By optimizing the geometric configuration, such as increasing the wall thickness or adding reinforcing ribs, the profiles can be further strengthened to meet the desired torsion load requirements. Overall, FRP pultrusion profiles excel in handling torsion loads due to their inherent properties, manufacturing process, and design flexibility. Their ability to resist twisting forces, coupled with their lightweight nature, makes them a reliable and cost-effective choice for various applications, including construction, infrastructure, aerospace, and automotive industries.

- Q: Can FRP pultrusion profiles be used in high-voltage applications?

- FRP pultrusion profiles are suitable for use in high-voltage applications due to their highly durable and electrically insulating nature. The material's consistency and uniform composition achieved through the pultrusion process ensure excellent electrical insulation properties. These profiles possess a high dielectric strength, enabling them to withstand high voltages without electrical breakdown. Additionally, they exhibit low electrical conductivity, preventing the flow of electric current. As a result, FRP profiles are ideal for applications requiring crucial electrical insulation, such as high-voltage power transmission and distribution systems, electrical substations, and equipment insulation. Aside from their electrical insulation capabilities, FRP pultrusion profiles offer numerous advantages in high-voltage applications. They are lightweight, corrosion resistant, and have a high strength-to-weight ratio, facilitating easy handling, installation, and maintenance. Furthermore, FRP profiles are non-magnetic and non-conductive, minimizing the risk of electromagnetic interference (EMI) in sensitive electrical systems. In conclusion, FRP pultrusion profiles are a dependable and efficient choice for high-voltage applications, providing exceptional electrical insulation, durability, and performance in challenging environments.

- Q: Are FRP pultrusion profiles resistant to sulfuric acid?

- FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to sulfuric acid. The corrosion resistance of FRP profiles is one of their key advantages compared to traditional materials like steel or concrete. Sulfuric acid is a highly corrosive substance, but FRP pultrusion profiles can withstand its effects due to the inherent properties of the composite materials used in their construction. The corrosion resistance of FRP profiles is mainly attributed to the resin matrix that encapsulates the reinforcing fibers. Most commonly used resins in pultrusion, such as polyester, vinyl ester, or epoxy, have excellent chemical resistance properties, including resistance to sulfuric acid. However, it is important to note that the resistance of FRP pultrusion profiles to sulfuric acid can vary depending on several factors. The concentration and temperature of the acid, as well as the specific resin formulation used in the profile, can influence the overall resistance. In highly concentrated or elevated temperature environments, it is advisable to consult with the manufacturer or supplier to ensure the specific FRP profile meets the required resistance level. In general, FRP pultrusion profiles offer a high level of resistance to sulfuric acid, making them suitable for various applications in industries where this corrosive substance may be present, such as chemical processing, wastewater treatment, or mining.

- Q: Can FRP pultrusion profiles be used in the automotive manufacturing industry?

- Certainly! Fiber Reinforced Polymer (FRP) pultrusion profiles have the potential to be utilized within the automotive manufacturing sector. These profiles possess a number of advantages that render them appropriate for automotive applications. To begin with, one of the key benefits of FRP profiles is their lightweight nature, which aids in reducing the overall weight of vehicles. This is of utmost importance in enhancing fuel efficiency and decreasing emissions. Moreover, the reduced weight of FRP profiles enables improved handling and enhanced performance. Additionally, FRP profiles exhibit exceptional mechanical properties, including high strength and stiffness. These properties make them well-suited for integration into structural components of vehicles, such as chassis, body panels, and frames. FRP profiles are able to withstand heavy loads and offer excellent impact resistance, thereby ensuring the safety of both the vehicle and its occupants. Furthermore, FRP profiles possess outstanding corrosion resistance, a quality that is particularly advantageous in automotive applications. In contrast to traditional materials like steel, FRP profiles are impervious to rust and corrosion. Consequently, they are ideally suited for deployment in various automotive environments, including those that involve exposure to moisture, chemicals, and salt. Moreover, FRP pultrusion profiles can be customized to meet specific design requirements, thereby affording flexibility in the manufacturing process. They can be produced in a range of shapes and sizes, which allows for the design of intricate components. This design flexibility also permits customization and optimization of vehicle performance. Lastly, FRP profiles possess excellent thermal and electrical insulation properties. This renders them appropriate for applications where minimizing electrical conductivity or providing thermal insulation is necessary. On the whole, the combination of the lightweight nature, high strength, corrosion resistance, design flexibility, and insulation properties of FRP pultrusion profiles positions them as an ideal choice for deployment within the automotive manufacturing industry. Their usage can contribute to the development of more efficient, safe, and durable vehicles.

- Q: Can FRP pultrusion profiles be used in the construction of outdoor signage?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of outdoor signage. FRP pultrusion profiles have excellent durability and resistance to weathering, making them suitable for outdoor applications. They are lightweight, corrosion-resistant, and can be customized into various shapes and sizes, making them ideal for signage purposes. Additionally, FRP pultrusion profiles offer high strength-to-weight ratio and can withstand harsh environmental conditions, ensuring long-lasting and reliable outdoor signage.

- Q: Are FRP pultrusion profiles resistant to nitric acid?

- FRP pultrusion profiles are generally resistant to nitric acid. Nitric acid is a strong oxidizing agent and can corrode many materials including metals. However, FRP (Fiber Reinforced Polymer) pultrusion profiles are made of composite materials that are specifically designed to be resistant to various corrosive substances, including nitric acid. The corrosion resistance of FRP pultrusion profiles can be attributed to the combination of their reinforcing fibers, such as fiberglass or carbon fiber, and the resin matrix that binds these fibers together. The resin matrix used in FRP profiles is typically a thermosetting polymer, such as polyester or epoxy, which provides a protective barrier against corrosive substances. Nitric acid is known to attack metals, causing corrosion and degradation. However, FRP pultrusion profiles offer excellent resistance to nitric acid due to the inert nature of the composite materials used. The reinforcing fibers in FRP profiles do not react with nitric acid, and the resin matrix acts as a barrier, preventing the acid from reaching and corroding the fibers. It is important to note that the specific resistance of FRP pultrusion profiles to nitric acid may vary depending on the specific composition of the composite materials used and the concentration and temperature of the nitric acid. Therefore, it is always recommended to consult with the manufacturer or supplier of FRP profiles to ensure their compatibility with nitric acid in specific applications.

- Q: Can FRP pultrusion profiles be used in electrical insulation applications?

- Yes, FRP pultrusion profiles can be used in electrical insulation applications. FRP (Fiber Reinforced Polymer) materials have excellent electrical insulation properties, making them suitable for a wide range of electrical applications. The pultrusion process ensures that the profiles have uniform insulation properties and high strength, making them ideal for use in electrical insulation applications.

- Q: Can FRP pultrusion profiles be used in the construction of chemical processing equipment?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles can be used in the construction of chemical processing equipment. FRP offers excellent resistance to corrosion, chemicals, and high temperatures, making it a suitable material for such applications. The pultrusion process ensures that the profiles are strong, durable, and have consistent properties, making them reliable for use in chemical processing equipment where resistance to corrosive substances is crucial.

Send your message to us

FRP Pultrusion Profiles - High Strength, Corrosion Resistant and Fire Resistant Fiberglass Grating for Platform, Walkway, Trench Cover

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords