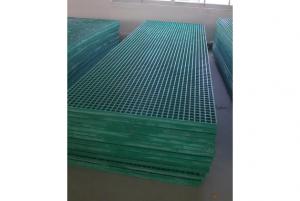

FRP Pultrusion Profiles - Corrosion Resistant and Fire Resistant FRP Gratings with Modern Shape/Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

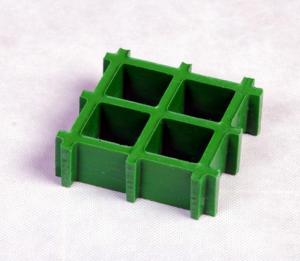

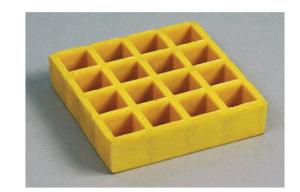

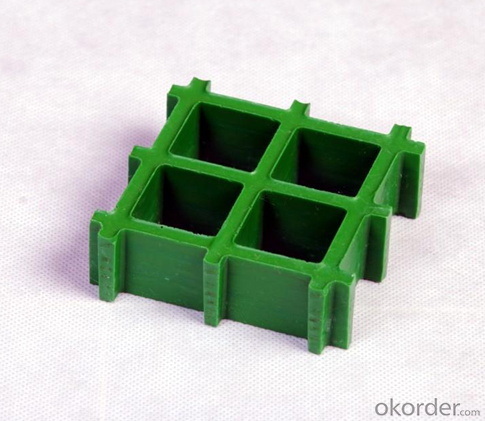

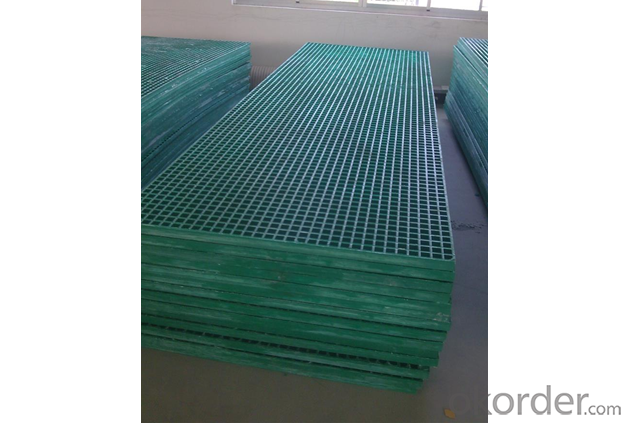

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

Fire Resistance

Light Weight & High Strength

Safety & Anti-slip

Electrical Insulating

Aging Resistance

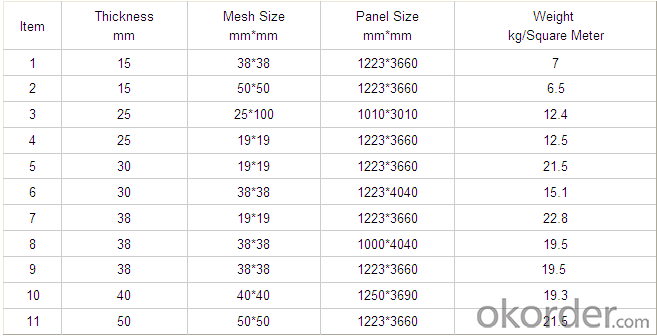

Specification

Advantage

- no maintenance

high strength

long service life

easy installation

Application

Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

- FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How is the package?

Usually, we arrange the standard out-package for exporting.

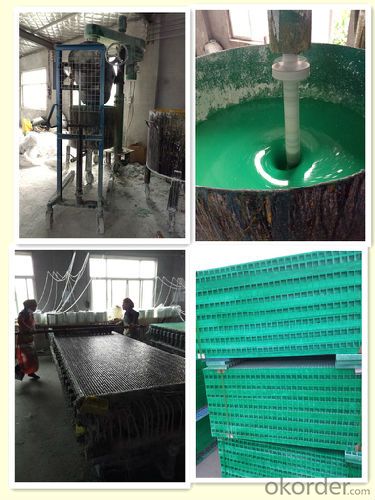

PROCESS

FACTORY

- Q: Are FRP pultrusion profiles resistant to moisture or humidity?

- FRP pultrusion profiles boast exceptional resistance to moisture and humidity. Through the pultrusion process, continuous fibers are thoroughly saturated with a polymer resin, resulting in a steadfast and enduring composite material. This composite possesses inherent moisture resistance, differing from conventional materials like wood or metal, as it does not absorb water. Moreover, FRP pultrusion profiles exhibit a minimal coefficient of thermal expansion, minimizing the likelihood of expansion or contraction in response to varying humidity levels. This moisture and humidity resistance render FRP pultrusion profiles suitable for a diverse array of applications, including outdoor structures, marine environments, and other areas prone to moisture.

- Q: Can FRP pultrusion profiles be used in water treatment plants?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in water treatment plants. FRP pultrusion profiles offer several advantages that make them well-suited for use in this industry. Firstly, FRP pultrusion profiles are highly corrosion resistant. Water treatment plants often have aggressive environments with exposure to chemicals and moisture, which can cause corrosion and degradation of traditional materials like steel. However, FRP pultrusion profiles are immune to corrosion, making them an ideal choice for water treatment applications. Secondly, FRP pultrusion profiles have excellent strength-to-weight ratios. This means that they provide high structural integrity while being lightweight, making them easier to handle and install in water treatment plants. Additionally, their high strength allows them to withstand the loads and pressures typically encountered in these environments. Furthermore, FRP pultrusion profiles are electrically non-conductive. This is particularly advantageous in water treatment plants, where there may be a need to isolate electrical equipment or components to prevent short circuits and protect personnel. FRP profiles provide a safe and reliable solution in such cases. Lastly, FRP pultrusion profiles have a long service life with minimal maintenance requirements. They do not rot, rust, or corrode, ensuring durability and longevity even in harsh water treatment conditions. This reduces downtime and maintenance costs, making FRP profiles a cost-effective choice for water treatment plant applications. Overall, FRP pultrusion profiles are an excellent choice for use in water treatment plants due to their corrosion resistance, high strength-to-weight ratio, electrical non-conductivity, and long service life. Their use can contribute to improved efficiency, reduced maintenance, and increased durability in water treatment processes.

- Q: How do FRP pultrusion profiles handle torsion loads?

- FRP pultrusion profiles are known for their excellent mechanical properties and high strength-to-weight ratio, making them an ideal choice for handling torsion loads. When subjected to torsion, these profiles are designed to withstand twisting forces and maintain their structural integrity. The key to their ability to handle torsion loads lies in their construction. FRP pultrusion profiles are manufactured by pulling reinforcing fibers, such as fiberglass, through a resin bath and then through a heated die. This process aligns the fibers in the direction of the load, providing exceptional strength and stiffness. In the case of torsion loads, the aligned fibers in the profile's cross-section resist the twisting force by distributing it along the length of the profile. This distribution of force helps prevent localized stress concentrations, reducing the risk of deformation or failure. Additionally, the resin matrix surrounding the fibers acts as a binding agent, holding the fibers together and providing protection against environmental factors such as moisture, chemicals, and UV radiation. This ensures the long-term durability and stability of the profile under torsion loads. Furthermore, FRP pultrusion profiles can be designed with specific cross-sectional shapes and dimensions to enhance their torsional strength. By optimizing the geometric configuration, such as increasing the wall thickness or adding reinforcing ribs, the profiles can be further strengthened to meet the desired torsion load requirements. Overall, FRP pultrusion profiles excel in handling torsion loads due to their inherent properties, manufacturing process, and design flexibility. Their ability to resist twisting forces, coupled with their lightweight nature, makes them a reliable and cost-effective choice for various applications, including construction, infrastructure, aerospace, and automotive industries.

- Q: Can FRP pultrusion profiles be used in telecommunications applications?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in telecommunications applications. FRP pultrusion profiles offer several advantages that make them suitable for telecommunications infrastructure. Firstly, FRP pultrusion profiles are lightweight yet strong, which makes them ideal for applications such as antenna supports, cable trays, and equipment racks. Their high strength-to-weight ratio allows for easier installation and transportation, while still providing the necessary structural support. Secondly, FRP pultrusion profiles are corrosion resistant, which is a crucial characteristic in telecommunication applications. Telecommunications infrastructure is often exposed to harsh environments, including moisture, chemicals, and extreme temperatures. Unlike traditional materials like steel or wood, FRP does not corrode or degrade in these conditions, ensuring long-term durability and reliability. Additionally, FRP pultrusion profiles offer electrical insulation properties, which is vital in telecommunications applications. They do not conduct electricity, making them safe for use in areas where electrical equipment is installed. This feature helps prevent electrical interference and ensures the integrity of the telecommunication system. Furthermore, FRP pultrusion profiles can be customized to meet specific design requirements. They can be manufactured in various shapes and sizes, allowing for flexibility in designing telecommunication infrastructure. This versatility makes FRP pultrusion profiles suitable for a wide range of applications within the telecommunications industry. In conclusion, FRP pultrusion profiles are well-suited for telecommunications applications due to their lightweight yet strong nature, corrosion resistance, electrical insulation properties, and customization possibilities. These attributes make them a reliable choice for supporting and protecting telecommunication infrastructure.

- Q: Can FRP pultrusion profiles be used in the agricultural and farming industry?

- Yes, FRP pultrusion profiles can certainly be used in the agricultural and farming industry. FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their high strength, durability, and resistance to corrosion, making them ideal for outdoor and harsh environments such as those found in the agricultural and farming industry. These profiles can be used for various applications in agriculture and farming, including: 1. Fencing and enclosures: FRP pultrusion profiles can be used to create sturdy and long-lasting fences, gates, and enclosures for livestock and crop protection. The profiles are resistant to rot, rust, and insect damage, providing a reliable barrier for animals and crops. 2. Structural components: FRP pultrusion profiles can be used as structural components in agricultural buildings, sheds, and greenhouses. Their high strength-to-weight ratio allows for the construction of lightweight and durable structures that can withstand extreme weather conditions. 3. Irrigation systems: FRP pultrusion profiles can be used in the construction of irrigation systems, such as pipes, channels, and culverts. These profiles are non-corrosive and have a smooth interior surface, reducing friction and improving water flow efficiency. 4. Equipment support and framing: FRP pultrusion profiles can be used to provide support and framing for various agricultural equipment, such as conveyors, platforms, and machinery. Their high strength and stiffness make them suitable for heavy-duty applications. 5. Animal housing and equipment: FRP pultrusion profiles can be used to construct animal housing and equipment, such as pens, stalls, and feeding troughs. These profiles are resistant to chemicals, moisture, and UV radiation, ensuring a long lifespan and low maintenance requirements. In summary, FRP pultrusion profiles can be successfully utilized in the agricultural and farming industry due to their excellent mechanical properties, resistance to environmental factors, and versatility in various applications.

- Q: Are FRP pultrusion profiles resistant to oil and grease?

- FRP pultrusion profiles are widely recognized for their exceptional ability to withstand oil and grease. The combination of fibers, typically glass or carbon, with a polymer resin matrix creates a material that is naturally resistant to numerous chemicals, including oil and grease. This resistance can be attributed to the non-reactive nature of the polymer resin, which prevents oil or grease from infiltrating the material and causing harm. Moreover, the pultrusion manufacturing process further enhances the profiles' resistance to oil and grease. In this process, the fibers are soaked in the resin and then drawn through a heated die, where the resin solidifies. This results in a sturdy, uniform material with a compact surface that is less porous and more capable of resisting chemical penetration. It is important to acknowledge that the specific resistance of FRP pultrusion profiles to oil and grease can vary depending on the resin used and the conditions of the application. In certain instances, specialized resin formulations can be employed to augment the profiles' oil and grease resistance, ensuring suitability for even the most demanding environments. Overall, FRP pultrusion profiles are widely regarded as highly resistant to oil and grease, making them an exceptional choice for applications exposed to these substances. However, it is always advisable to consult with the manufacturer or supplier to confirm that the specific FRP profile being utilized is suitable for the intended application and chemical exposure.

- Q: What are the features of Glass Fiber Reinforced Plastic Pultruded materials and chairs?

- Glass reinforced plastic extruded section bar has the characteristics of unlimited length, high utilization rate of raw material, corrosion resistance, good weatherability and long service life

- Q: Plastic or better glass fiber reinforced plastic better?

- Plastic steel and glass fiber reinforced plastic have their own advantages, in the mechanical manufacturing and vehicles, ships and other industrial fields, glass fiber reinforced plastic is used; in furniture decoration, the use of plastic steel profiles.

- Q: Can FRP pultrusion profiles be used in the construction of oil storage tanks?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of oil storage tanks. These profiles provide excellent corrosion resistance, high strength-to-weight ratio, and durability, making them suitable for storing various chemicals, including oil. Additionally, FRP pultrusion profiles are easily customizable, allowing for the construction of tanks of different sizes and shapes to meet specific requirements.

- Q: Are FRP pultrusion profiles resistant to impact?

- FRP pultrusion profiles exhibit a general resistance to impact. The amalgamation of robust fibers and the polymer matrix employed during manufacturing renders FRP profiles exceptionally enduring, enabling them to endure substantial impacts without fracturing or shattering. Furthermore, the pultrusion process guarantees the uniform dispersion of fibers within the profile, thereby bolstering its capacity to resist impact. Consequently, FRP pultrusion profiles are ideally suited for impact-prone applications, including construction, transportation, and infrastructure ventures.

Send your message to us

FRP Pultrusion Profiles - Corrosion Resistant and Fire Resistant FRP Gratings with Modern Shape/Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords