FRP Pultrusion Profiles - High Specific Intensity FRP Pultruded Gratings On Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

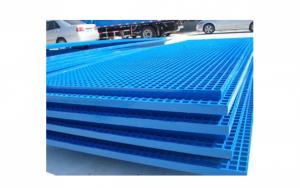

FRP PULTRUDED GRATING AND PULTRUSION PROCESS

PRODUCT DESCRIPTION

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

FRP pultruded grating has the most characteristics of molded grating, but it has its distinct advantages, it has very high fiberglass content in the loading direction, so it has very high load capability, it has more superiority when used at wide span, so that the basic support will be decreased and the project cost will be reduced accordingly.

SPECIFICATION

The standard space between two crossbars is 6 inch or 12 inch.

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

f. Anti-ageing

g. Easy of maintenance

h. Excellent electromagnetism property

i. Good economic benefit

FIELDS SERVED

Sewage treatment,

water supply and drainage,

chemical industry,

oil industry,

power engineering,

pulp and paper,

construction engineering,

spinning, marine engineering.

APPLICATION

Operation terrace,

stair walkway,

ground floor,

trench cover,

sidewalk,

foot bridge,

equipment safety fence,

scaffold.

COMPANT DESCRIPTION

CNBM,China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

FAQ

1.Q:Are you factory or trading company ?

A:We are Factory produce FRP machines and FRP products.

2.Q:If can customized by customers requirements?

A:yes,we can produce the machine with customized size.

3.Q:How about the payment?

A:We accept any kind of payment.

4.Q:What is the guarantee?

A:Gurantee is one year.

5.Q:If you can training?

A:yes ,we can training in our factory also can send engineers to your factory training.

PICTURES

- Q: Are FRP pultrusion profiles resistant to biological growth, such as mold or mildew?

- FRP pultrusion profiles are highly resistant to biological growth, such as mold and mildew. These profiles have a non-porous structure that makes it difficult for microorganisms to attach and grow. They are typically made with a combination of resin and glass fibers, both of which naturally resist biological growth. In contrast to materials like wood or metal, FRP does not create an ideal environment for mold or mildew. The smooth and non-porous surface of FRP prevents moisture absorption, which is necessary for microorganisms to thrive. Additionally, FRP materials lack organic compounds that can support the growth of mold or mildew, thus enhancing their resistance to biological degradation. When it comes to applications that require resistance to biological growth, FRP pultrusion profiles offer a significant advantage over other materials. They are commonly used in environments with high humidity, moisture, or water exposure, such as marine, agricultural, or wastewater treatment facilities. Furthermore, FRP profiles are frequently employed indoors in areas where mold or mildew growth is a concern, such as sanitary areas or food processing plants. Overall, FRP pultrusion profiles are an excellent solution for combating biological growth, including mold and mildew. Their non-porous nature, combined with the inherent resistance of the materials used in their manufacturing, ensures durability and longevity in environments where microbial growth is a potential issue.

- Q: Are FRP pultrusion profiles resistant to impact?

- Yes, FRP pultrusion profiles are generally resistant to impact. The combination of fibreglass reinforcement and resin matrix in FRP pultrusion profiles provides high strength and stiffness, making them less susceptible to damage from impact compared to other materials such as wood or metal. However, the impact resistance may vary depending on the specific design and composition of the FRP profile.

- Q: Are FRP pultrusion profiles resistant to high-pressure gas?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to high-pressure gas. FRP materials have excellent chemical resistance and are often used in applications where they come into contact with various chemicals, including gases under high pressure. The specific resistance of FRP pultrusion profiles to high-pressure gas will depend on the specific resin and reinforcement used in their construction. It is important to consult the manufacturer's specifications and guidelines to ensure that the specific FRP profiles being used are suitable for the intended high-pressure gas application.

- Q: Are FRP pultrusion profiles resistant to impact from flying debris?

- FRP pultrusion profiles possess notable strength and durability, earning them a reputation in the industry. Their inherent properties make them generally impervious to damage caused by flying debris. This exceptional impact resistance can be attributed to the combination of reinforcing fibers, often fiberglass, and the polymer matrix. The extent of resistance to flying debris impact may vary depending on the design, thickness, and composition of the FRP pultrusion profiles. Nevertheless, these profiles are typically engineered to withstand impact forces and effectively withstand damage from airborne debris. Moreover, FRP pultrusion profiles find extensive use in industries such as construction, transportation, and infrastructure, where impact resistance is of utmost importance. These profiles have undergone rigorous testing and have demonstrated their ability to endure various impact scenarios, making them a trustworthy choice for applications that involve the potential for flying debris. It is vital to recognize that although FRP pultrusion profiles boast commendable impact resistance, the severity of the impact and the speed of the flying debris can still impact the degree of damage incurred. Thus, it is advisable to consult with the manufacturer or an engineer to ensure the chosen FRP profile is suitable for the intended application and potential impact conditions.

- Q: Can FRP pultrusion profiles be used in wastewater or sewage treatment plants?

- Yes, FRP pultrusion profiles can be used in wastewater or sewage treatment plants. FRP (Fiber Reinforced Plastic) materials offer excellent corrosion resistance, high strength-to-weight ratio, and durability, making them suitable for harsh environments like wastewater treatment facilities. These profiles can be used for various applications such as gratings, handrails, ladders, walkways, and structural supports, providing a long-lasting and low-maintenance solution for these facilities.

- Q: Can FRP pultrusion profiles be used in mining applications?

- Yes, FRP pultrusion profiles can be used in mining applications. FRP (Fiber Reinforced Polymer) pultrusion profiles offer excellent strength-to-weight ratio, corrosion resistance, and durability, making them suitable for various mining applications such as support structures, ventilation systems, walkways, and equipment enclosures. Additionally, FRP profiles are non-conductive and non-magnetic, making them ideal for underground mining environments.

- Q: Are FRP pultrusion profiles resistant to moisture absorption?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to moisture absorption. This is due to the nature of the material used in their construction, which typically includes a combination of fiberglass and resin. Fiberglass is inherently non-porous and does not absorb moisture, while the resin used in FRP pultrusion profiles is specifically formulated to be moisture-resistant. The pultrusion process used to manufacture FRP profiles also contributes to their moisture resistance. During pultrusion, the fiberglass and resin are pulled through a heated die, which not only ensures thorough impregnation of the fibers with resin but also creates a solid, dense structure. This results in a product that is highly resistant to water penetration and moisture absorption. Furthermore, FRP pultrusion profiles can be further enhanced with the addition of protective coatings or surface treatments, such as gel coats or UV-resistant finishes, which provide an additional barrier against moisture ingress. The moisture resistance of FRP pultrusion profiles makes them an excellent choice for applications where exposure to water or high humidity is expected, such as in marine environments, wastewater treatment plants, or outdoor structures. Their resistance to moisture absorption helps to prevent issues like rot, rust, or degradation commonly associated with other materials like wood or metal. Overall, FRP pultrusion profiles offer a reliable and durable solution that can withstand moisture exposure without compromising their structural integrity or performance.

- Q: Do FRP pultrusion profiles have any limitations or drawbacks?

- FRP pultrusion profiles indeed have certain limitations and drawbacks that need to be taken into account. One of these limitations is their lower stiffness compared to traditional materials like steel or aluminum. As a result, they may not be suitable for applications that demand high structural rigidity or heavy loads. Another constraint is their susceptibility to creep, which refers to the gradual deformation of the material under a constant load over time. This can adversely affect the long-term performance and durability of the profiles, particularly in scenarios where they face sustained stress. Moreover, FRP pultrusion profiles generally incur higher production costs compared to traditional materials. The manufacturing process involves pultruding continuous fibers through a resin matrix, requiring specialized equipment and expertise. Consequently, the higher production expenses make FRP pultrusion profiles less economically viable for certain applications. Additionally, FRP pultrusion profiles are typically not suitable for high-temperature applications. The resin matrix used in their production can degrade or soften at elevated temperatures, thereby restricting their use in environments where thermal resistance is crucial. Finally, FRP pultrusion profiles may have limited design flexibility compared to other materials. The pultrusion process typically yields profiles with constant cross-sections and limited geometric complexity. Consequently, their use is restricted in applications that necessitate intricate shapes or customized designs. Despite these limitations, FRP pultrusion profiles offer several advantages, such as a high strength-to-weight ratio, corrosion resistance, and electrical insulation properties. Therefore, it is crucial to thoroughly consider the specific requirements of the application before opting for FRP pultrusion profiles.

- Q: Can FRP pultrusion profiles be used in the production of electrical insulators?

- Indeed, FRP pultrusion profiles have the potential to be utilized in the manufacturing of electrical insulators. These profiles are renowned for their exceptional electrical insulation characteristics, rendering them appropriate for a wide array of electrical applications. The non-conductive and high-strength attributes of FRP materials make them an ideal choice for insulating components within electrical systems, including insulators. The creation of FRP pultrusion profiles entails saturating continuous fibers like fiberglass, carbon fiber, or aramid with a polymer resin, which is subsequently solidified and shaped through the pultrusion process. This process yields a resilient and lightweight material that exhibits remarkable electrical insulation properties. Electrical insulators serve the purpose of obstructing the flow of electric current between conductive materials or components. They are indispensable in electrical systems as they ensure safety and prevent electrical leakage or short circuits. FRP pultrusion profiles can be tailored and manufactured to meet the specific requisites of electrical insulators, encompassing dimensional accuracy, mechanical strength, and electrical insulation performance. Moreover, FRP pultrusion profiles offer numerous advantages when compared to conventional materials such as wood, porcelain, or ceramics. They possess corrosion resistance, possess a high strength-to-weight ratio, and can be easily customized to fulfill the specific demands of electrical insulator applications. Furthermore, FRP pultrusion profiles are non-conductive, a pivotal factor for electrical insulation. In summary, owing to their exceptional electrical insulation properties, durability, lightweight nature, and customization possibilities, FRP pultrusion profiles are exceedingly suitable for the production of electrical insulators.

- Q: Do FRP pultrusion profiles require any special tools for installation?

- Yes, FRP pultrusion profiles do require special tools for installation. These tools typically include saws for cutting the profiles to size, drills for creating holes, and adhesive application tools for bonding the profiles to the substrate. Additionally, specialized fasteners and brackets may be needed to secure the profiles in place. It is important to use these tools correctly to ensure a proper and secure installation of FRP pultrusion profiles.

Send your message to us

FRP Pultrusion Profiles - High Specific Intensity FRP Pultruded Gratings On Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords