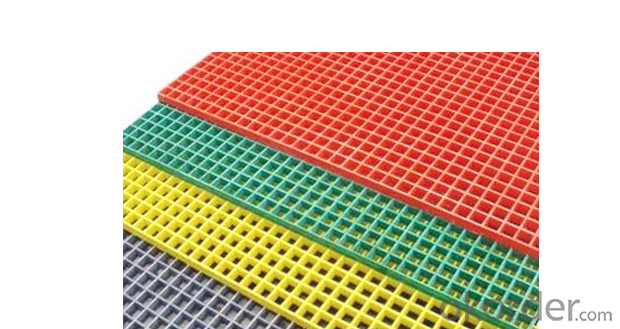

FRP Pultrusion Profiles - FRP Gratings, FRP Molded Gratings, FRP Fiberglass Plastic Walkway Gratings in Various Colors

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

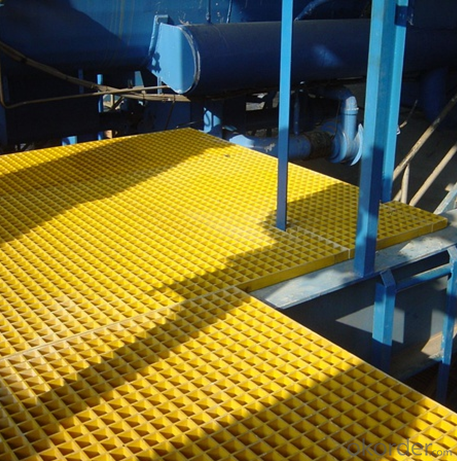

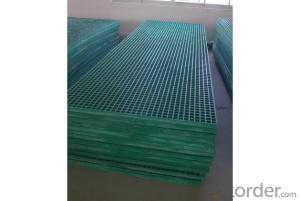

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

l Corrosion Resistance

l Fire Resistance

l Light Weight & High Strength

l Safety & Anti-slip

l Electrical Insulating

l Aging Resistance

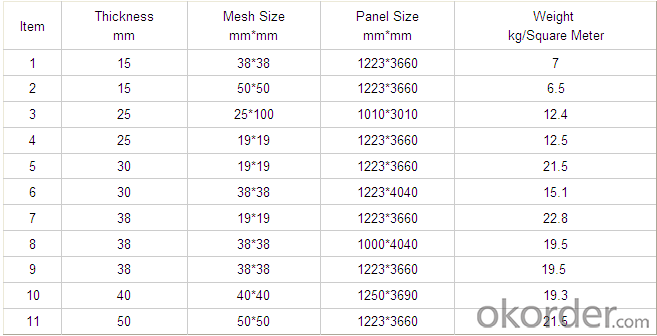

Specification

Advantage

1) coated with prevent aging layer

2) excellent insulating performance

3) no maintenance

4) high strength

5) long service life

6) easy installation

Application

l Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

l In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

l Pool railings in sewage treatment industry

l Corrosive chemical industry equipment around the fence

l All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

4. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

5. How is the package?

Usually, we arrange the standard out-package for exporting.

PROCESS

FACTORY

- Q: Can FRP pultrusion profiles be used in agricultural structures?

- Yes, FRP pultrusion profiles can be used in agricultural structures. FRP (Fiber Reinforced Polymer) pultrusion profiles offer several advantages that make them suitable for agricultural applications. Firstly, FRP profiles are corrosion-resistant, which is crucial in the agricultural industry where structures are exposed to harsh environments and chemicals, such as fertilizers and pesticides. Unlike traditional materials like steel or wood, FRP does not rust or decay, ensuring long-lasting performance in agricultural structures. Secondly, FRP profiles are lightweight yet durable, making them easy to handle and install in agricultural applications. They have high strength-to-weight ratios, allowing for efficient construction and reducing the need for heavy machinery during installation. Additionally, FRP profiles offer excellent mechanical properties such as high stiffness and impact resistance, which are beneficial for agricultural structures that may face heavy loads, vibrations, or impact from machinery. Furthermore, FRP pultrusion profiles can be designed to be UV resistant, preventing degradation from prolonged exposure to sunlight. This makes them suitable for outdoor agricultural structures that are constantly exposed to the elements. Lastly, FRP profiles are non-conductive, which is advantageous in agricultural environments where electrical safety is critical. This property eliminates the risk of electrical hazards associated with conductive materials like steel. Overall, FRP pultrusion profiles provide a reliable and efficient solution for various agricultural structures, such as greenhouse frames, livestock enclosures, irrigation systems, and storage facilities. Their corrosion resistance, lightweight nature, high strength, UV resistance, and non-conductivity make them a suitable choice for agricultural applications.

- Q: Are FRP pultrusion profiles resistant to biological growth, such as mold or mildew?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to biological growth, including mold and mildew. FRP materials are inherently non-porous, making it difficult for microorganisms to attach and grow on their surface. Additionally, FRP pultrusion profiles are typically manufactured using a combination of resin and glass fibers, which are both naturally resistant to biological growth. Unlike traditional materials such as wood or metal, FRP does not provide an ideal environment for mold or mildew to thrive. The smooth and non-porous surface of FRP profiles prevents moisture absorption, which is essential for the growth of microorganisms. Furthermore, FRP materials do not contain organic compounds that can support the growth of mold or mildew, making them highly resistant to biological degradation. In applications where resistance to biological growth is crucial, FRP pultrusion profiles offer a significant advantage over alternative materials. They are commonly used in environments with high humidity, moisture, or exposure to water, such as marine, agricultural, or wastewater treatment facilities. Additionally, FRP profiles are frequently employed in indoor applications where mold or mildew growth can be a concern, such as in sanitary areas or food processing plants. Overall, FRP pultrusion profiles provide excellent resistance to biological growth, including mold and mildew. Their non-porous nature, combined with the inherent resistance of the materials used in their manufacturing, make them a durable and long-lasting solution in environments where microbial growth is a potential issue.

- Q: Can not use glass steel support column, the main support for the door

- The epoxy pultruded glass steel section is of high strength and can meet your requirement. You can choose the required section according to your requirement

- Q: Are FRP pultrusion profiles resistant to chemicals used in agricultural applications?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to chemicals used in agricultural applications. FRP pultrusion profiles are made from a combination of reinforced fibers and a polymer resin matrix, typically polyester or vinyl ester. These materials provide excellent resistance to a wide range of chemicals commonly used in agriculture, such as fertilizers, pesticides, herbicides, and various acids. The inherent corrosion resistance of FRP pultrusion profiles makes them a preferred choice in agricultural applications where exposure to chemicals is common. Unlike traditional materials like wood, steel, or concrete, FRP profiles do not deteriorate or degrade when exposed to aggressive chemicals. This resistance ensures that the profiles maintain their structural integrity and performance over a long lifespan, even under harsh agricultural conditions. Furthermore, FRP pultrusion profiles offer superior resistance to corrosion, moisture, UV radiation, and temperature fluctuations. These properties make them highly durable and suitable for a wide range of agricultural applications, including structural supports, fencing, grating, decking, and irrigation systems. It is important to note that while FRP pultrusion profiles are highly resistant to chemicals, they may still experience some level of degradation or staining when exposed to extremely concentrated or highly aggressive chemicals. Therefore, it is recommended to consult with the manufacturer or supplier to ensure that the specific chemicals used in the agricultural application are compatible with the chosen FRP pultrusion profiles.

- Q: Can FRP pultrusion profiles be used in the construction of solar panel frames?

- FRP pultrusion profiles are a viable option for constructing solar panel frames. These profiles possess qualities such as being lightweight, strong, and corrosion-resistant, making them an ideal material choice. Their durability and high strength-to-weight ratio ensure that the frames can withstand different weather conditions and prolonged exposure to sunlight. Moreover, FRP pultrusion profiles can be easily customized to meet specific design requirements, providing flexibility in solar panel frame construction. All in all, utilizing FRP pultrusion profiles in this industry offers multiple benefits, making it a suitable choice for the solar energy sector.

- Q: Are FRP pultrusion profiles resistant to chemicals used in oil refineries?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to chemicals used in oil refineries. The composition of FRP profiles includes a combination of high-strength fibers, such as fiberglass, carbon fibers, or aramid fibers, embedded in a polymer resin matrix. This unique construction provides excellent resistance to a wide range of chemicals, including those commonly found in oil refineries. The polymer resin matrix used in FRP profiles can be carefully selected to withstand harsh chemical environments. For instance, vinyl ester or epoxy resins are often used in the manufacturing of FRP profiles for oil refinery applications due to their superior chemical resistance properties. Moreover, FRP pultrusion profiles are inherently corrosion-resistant, unlike traditional materials like steel or concrete, which can deteriorate when exposed to aggressive chemicals found in oil refineries. This corrosion resistance ensures the long-term durability and reliability of FRP profiles in such environments. Additionally, FRP profiles offer several other advantages in oil refinery applications, including high strength-to-weight ratio, electrical insulation, non-magnetic properties, and ease of installation. These characteristics make FRP pultrusion profiles an ideal choice for various structural, piping, and equipment applications within oil refineries. However, it is essential to consider the specific chemicals and concentrations involved in a particular oil refinery application. While FRP profiles generally exhibit excellent resistance to a wide range of chemicals, there might be certain highly concentrated or specialized chemicals that could potentially affect their performance. In such cases, it is advisable to consult with FRP manufacturers or experts who can provide tailored solutions to meet the specific chemical resistance requirements of the oil refinery.

- Q: Can FRP pultrusion profiles be customized according to specific requirements?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be customized according to specific requirements. Pultrusion is a manufacturing process that involves pulling continuous fibers through a liquid resin bath, then through a heated die to cure the resin and form the desired shape. This process allows for great flexibility in design and customization. The customization options for FRP pultrusion profiles include various dimensions, shapes, colors, and surface finishes. The dimensions can be tailored to meet specific length, width, and thickness requirements. The shapes can range from basic geometries like rectangular or round profiles to more complex designs with custom cross-sections. In terms of color, FRP pultrusion profiles can be pigmented during the manufacturing process to achieve the desired color or can be painted or coated afterwards. This allows for matching specific color requirements or ensuring compatibility with existing structures or products. Furthermore, surface finishes can be customized to achieve desired properties such as increased slip resistance, UV resistance, or fire resistance. Surface treatments like sanding, coating, or adding special additives can be applied to meet specific performance requirements. Overall, FRP pultrusion profiles offer a high level of customization to meet specific project or application needs. They are versatile, lightweight, corrosion-resistant, and have excellent strength-to-weight ratios, making them suitable for various industries such as construction, transportation, infrastructure, and aerospace.

- Q: Are FRP pultrusion profiles resistant to chemicals used in mining operations?

- FRP pultrusion profiles, commonly referred to as Fiber Reinforced Polymer, generally exhibit resistance to chemicals commonly used in mining operations. These profiles are well-known for their exceptional chemical resistance properties, making them suitable for a variety of corrosive environments, including mining operations. To provide resistance against the vast array of chemicals typically found in mining applications, such as acids, alkalis, solvents, and corrosive gases, the resin matrix used in FRP pultrusion profiles can be carefully selected. Additionally, the reinforcement fibers, often composed of glass or carbon, further enhance the overall chemical resistance of the profile. Moreover, FRP pultrusion profiles are non-conductive, making them an ideal choice for both electrical and mining applications. They are not susceptible to corrosion or degradation when exposed to chemicals, ensuring their durability and longevity in harsh mining environments. However, it is crucial to consider the specific chemicals and concentrations used in mining operations. Although FRP pultrusion profiles generally possess excellent chemical resistance, prolonged exposure to highly aggressive chemicals or high concentrations may necessitate additional measures. These measures could include selecting specific resin systems or applying surface coatings to ensure optimal performance and longevity. To determine the most suitable materials for specific mining chemical environments, it is advisable to consult with FRP manufacturers or experts.

- Q: Can FRP pultrusion profiles be used in the construction of agricultural structures?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of agricultural structures. FRP pultrusion profiles offer several advantages that make them suitable for agricultural applications. Firstly, FRP pultrusion profiles are lightweight yet strong, making them ideal for constructing agricultural structures such as greenhouses, barns, and storage facilities. Their high strength-to-weight ratio allows for easy installation and reduces the overall weight of the structure, thereby minimizing the need for heavy machinery during construction. Secondly, FRP pultrusion profiles are corrosion-resistant, which is a crucial characteristic for agricultural structures that are exposed to various environmental elements such as moisture, chemicals, and fertilizers. Unlike traditional materials like wood or steel, FRP does not rot, rust, or corrode, ensuring the longevity and durability of the agricultural structure. Additionally, FRP pultrusion profiles offer excellent electrical insulation properties. This is particularly beneficial in agricultural applications where electrical equipment, such as lighting systems or ventilation controls, are commonly used. The non-conductive nature of FRP prevents the risk of electrical shocks or short circuits. Moreover, FRP pultrusion profiles are highly customizable and can be designed to meet specific requirements. This flexibility allows for the creation of structures that are tailored to the unique needs of agricultural operations, such as load-bearing capacity, dimensional accuracy, and thermal insulation. Furthermore, FRP pultrusion profiles are non-magnetic, making them suitable for use in agricultural structures where magnetic interference can disrupt sensitive equipment or affect the growth of crops. Overall, the use of FRP pultrusion profiles in the construction of agricultural structures offers numerous benefits, including lightweight construction, corrosion resistance, electrical insulation, customization options, and non-magnetic properties. These advantages make FRP pultrusion profiles a viable and practical choice for agricultural applications.

- Q: Are FRP pultrusion profiles resistant to hydraulic oils?

- Yes, FRP pultrusion profiles are generally resistant to hydraulic oils. The combination of fiberglass reinforcement and resin matrix used in pultrusion manufacturing makes these profiles highly resistant to various chemicals, including hydraulic oils. However, it is recommended to consult the specific resin manufacturer or supplier for detailed information on the compatibility of their FRP pultrusion profiles with different types of hydraulic oils.

Send your message to us

FRP Pultrusion Profiles - FRP Gratings, FRP Molded Gratings, FRP Fiberglass Plastic Walkway Gratings in Various Colors

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords