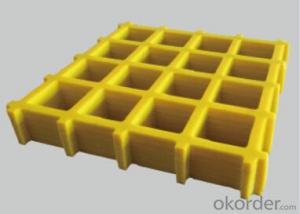

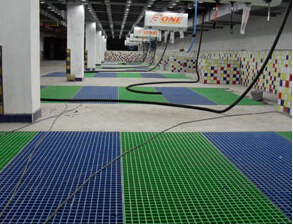

FRP Pultrusion Profiles for Carwash Floor Gratings

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of FRP Grating:

Light weight of FRP grating: the proportion of it is about 1.8, its weight was only about a quarter of the steel, is two-thirds of aluminum;

High strength of FRP grating: the strength is ten times the rigid polyvinyl chloride (PVC), absolute strength much more than aluminum, to achieve the level of the ordinary steel;

Corrosion resistanceof FRP grating: it does not rust, no mold, no corruption, no need to paint, can a lot of gas and liquid medium corrosion;

Fatigue resistance of FRP grating: FRP gratings have some flexibility, which makes people working on it for a long time to feel comfortable, as a work platform, reduce the staff in the legs and back tension and increase the work of comfort, so as to improve the work efficiency, recommended by human engineers;

Comprehensive economic benefit is good: with ordinary carbon steel, FRP grating comprehensive cost is low, although its one-time investment is higher than the ordinary carbon steel, because of its long service life, generally can be used for twenty years, and no maintenance, thus FRP grating's comprehensive economic benefit is significantly superior to use carbon steel;

Convenient installation of FRP grating: the use of FRP gratings greatly reduce components weight, thereby reducing the weight of the support structure, do not need to use the lifting equipment installation, saving and convenient.

Security of FRP grating: in the process of installation and use of FRP grating will not produce edm by collision, especially suitable for use in flammable and explosive environment, in addition, with non-slip surface of the grating can prevent slipping, reduce accidents;

To sum up, FRP grating compared with the traditional metal and non-metal materials, FRP grating materials and products, with high strength, good performance, energy conservation, product design degrees of freedom, and product use wide adaptability, etc. Therefore, in a certain sense, the FRP grating materials is a kind of a wide range of application, one of the great varieties of materials development prospects.

- Q: Are FRP pultrusion profiles resistant to chemicals used in food packaging?

- Yes, FRP pultrusion profiles are generally resistant to the chemicals commonly used in food packaging. The combination of fiberglass reinforcement and resin matrix used in FRP profiles provides excellent chemical resistance, making them a suitable choice for applications involving contact with food packaging chemicals. However, it is always recommended to consult with the manufacturer or supplier to ensure specific compatibility with the chemicals involved.

- Q: Are FRP pultrusion profiles resistant to wear or abrasion?

- Yes, FRP pultrusion profiles are highly resistant to wear and abrasion. The combination of strong reinforcing fibers and a durable resin matrix makes them capable of withstanding harsh conditions and maintaining their structural integrity over time, even in high-stress environments. This resistance to wear and abrasion makes FRP pultrusion profiles an excellent choice for applications that require long-lasting and low-maintenance solutions.

- Q: What is the compression strength of FRP pultrusion profiles?

- The compression strength of FRP (Fiber Reinforced Polymer) pultrusion profiles varies depending on several factors such as the type of resin, fiber orientation, and design. However, on average, FRP pultrusion profiles have a compression strength ranging from 10,000 to 50,000 pounds per square inch (psi). It is important to note that these values are approximate and may vary depending on the specific application and intended use of the FRP profiles. Additionally, manufacturers typically provide technical data sheets that outline the compression strength and other mechanical properties of their FRP pultrusion products, which can be utilized for more accurate and reliable information.

- Q: How do FRP pultrusion profiles compare to traditional materials, such as steel or aluminum?

- FRP pultrusion profiles offer several advantages over traditional materials like steel or aluminum. Firstly, FRP profiles are much lighter in weight, making them easier to handle and install. Additionally, FRP profiles possess excellent corrosion resistance, making them a suitable choice for applications in harsh environments. They also have high strength-to-weight ratio, allowing for efficient load-bearing capabilities. Furthermore, FRP profiles are non-conductive and do not require any additional insulation, making them ideal for electrical applications. Lastly, FRP profiles are highly customizable, enabling the design of complex shapes and sizes. Overall, FRP pultrusion profiles provide a cost-effective, durable, and versatile alternative to traditional materials.

- Q: Can FRP pultrusion profiles be used in the construction of amusement park rides?

- Yes, FRP pultrusion profiles can be used in the construction of amusement park rides. FRP (Fiber Reinforced Polymer) pultrusion profiles offer high strength-to-weight ratio, corrosion resistance, and durability, making them suitable for various applications in amusement park rides. These profiles can be used for structural components, such as supports, frames, and beams, as well as for aesthetic elements like facades or decorative structures. Additionally, FRP pultrusion profiles can be customized to meet specific design requirements, making them a versatile choice for constructing amusement park rides.

- Q: Can FRP pultrusion profiles be used in high-voltage applications?

- Yes, FRP pultrusion profiles can be used in high-voltage applications. FRP (Fiber Reinforced Polymer) materials are known for their excellent electrical insulation properties, making them suitable for high-voltage environments. Additionally, FRP pultrusion profiles offer advantages such as high strength, corrosion resistance, and lightweight, making them a viable option for high-voltage applications.

- Q: Are FRP pultrusion profiles resistant to sulfuric acid?

- Yes, FRP pultrusion profiles are generally resistant to sulfuric acid due to the corrosion-resistant properties of the fiber-reinforced plastic material. However, it is important to consider the concentration and temperature of the sulfuric acid, as extreme conditions can potentially affect the resistance of FRP profiles.

- Q: Can FRP pultrusion profiles be used in pedestrian bridges?

- FRP pultrusion profiles can indeed be utilized in pedestrian bridges. They possess several advantages that render them appropriate for bridge construction, including their exceptional strength-to-weight ratio, resistance to corrosion, and durability. These profiles are manufactured by pulling continuous fibers through a resin bath and subsequently through a heated die, yielding a material that is both robust and lightweight. The lightweight nature of FRP pultrusion profiles makes them an ideal choice for pedestrian bridges, as they can be easily transported and installed. Furthermore, their high strength enables them to withstand the load requirements imposed by pedestrian traffic. Moreover, these profiles exhibit exceptional resistance to corrosion, which is particularly crucial for bridges that are exposed to environmental elements such as rain, humidity, and saltwater. In addition, FRP pultrusion profiles are highly durable and necessitate minimal maintenance in comparison to traditional construction materials like steel or concrete. They are impervious to rust or rot, and their non-conductive properties guarantee their safety when employed in areas with electrical infrastructure. To summarize, FRP pultrusion profiles present a suitable option for pedestrian bridges due to their lightweight nature, high strength, resistance to corrosion, and durability. These profiles offer a cost-effective and long-lasting solution for bridge construction, ensuring the safety and convenience of pedestrians.

- Q: How do FRP pultrusion profiles handle bending and flexing?

- FRP pultrusion profiles are known for their exceptional durability and effective handling of bending and flexing. The pultrusion manufacturing process, which involves pulling reinforcing fibers through a resin bath and curing it in a heated die, creates a composite material with a remarkable strength-to-weight ratio. In terms of bending, FRP pultrusion profiles demonstrate outstanding flexibility. The reinforcing fibers, such as fiberglass or carbon fibers, provide the necessary tensile strength to resist bending forces. Moreover, the resin matrix surrounding the fibers adds elasticity, allowing the profiles to flex without breaking or permanently deforming. The bending and flexing capabilities of pultrusion profiles are also influenced by their specific design. Manufacturers can customize the profiles by adjusting the arrangement, orientation, and number of reinforcing fibers to meet specific application requirements. This enables them to enhance strength and flexibility in desired directions while maintaining structural integrity. Additionally, FRP pultrusion profiles possess inherent resistance to corrosion, moisture, and chemicals, which makes them ideal for use in harsh environments. These properties ensure that the profiles remain strong and unaffected over time, even when subjected to repeated bending and flexing. In summary, FRP pultrusion profiles are well-suited for handling bending and flexing due to their inherent strength, flexibility, and resistance to environmental factors. Their ability to maintain structural integrity under such conditions makes them a reliable choice for various industries, including construction, infrastructure, aerospace, and automotive.

- Q: Plastic or better glass fiber reinforced plastic better?

- Plastic steel and glass fiber reinforced plastic have their own advantages, in the mechanical manufacturing and vehicles, ships and other industrial fields, glass fiber reinforced plastic is used; in furniture decoration, the use of plastic steel profiles.

Send your message to us

FRP Pultrusion Profiles for Carwash Floor Gratings

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords