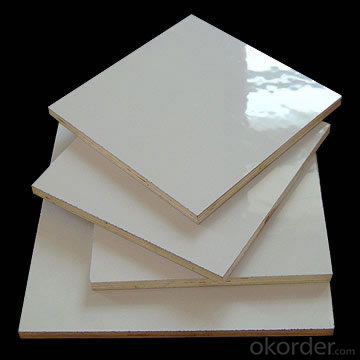

FIBER REINFORCE PLASTIC PANEL/ROOFING SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

FRP Sheet is made of high performance glass fibers and high quality ofunsaturated polyester resin.

Applications: sandwich panels,refrigerator car,decorative sheets, truck box body, wagon panels, dry vansheets, container panels, trailer panels, outdoor vacation panels, foodprocessing plants, cold storage, brewing beer plants, pharmaceutical factories,laboratories, hospitals, chemical plants, public bathhouses, toilets,warehouses, supermarkets, pleasure ground, schools, car washing, and yachts .Suitable for versatile indoor applications and without varnishing also foroutdoor use.

performance parameters:

1. impact resistance : Because theproduct structure contains crisscrossed glass fiber reinforced materials, greatly improve the shock resistance of the product, not easily brokendeformation...

2. corrosion resistance : It can resist kinds of acid, alkali and other chemical corrosion, especially suitablefor practical in the coastal and corrosive..

3. Easy-maintainable : FRP sheets maintenance isvery convenient, and no obvious trace after maintenance .

4. Coefficient of heat conductivity of FRPsheet is about 0.23KW/M.K,Its heat insulation performance is better than thatof steel and aluminum material..

5.Suface property: surface of FRP sheet is colorplastic suits, property is good, It can be made of food grade gelcoating,as it has this coating,the composite surface will be soomth and clean.

Product Traits

1. Corrosion resistance no rust, no maintenance, long service life.

2. Lightweight, high strength pultrusion process molding FRP profiles have high glass fiber content (60%). In this situation, the density of glass fiber reinforced plastic is only about a quarter of the steel.

3. The intensity and stiffness is quite prominent,.

4. Anti-fatigue high anti- fatigue strength, allowing repeated bending without permanent deformation.

5. Anti-aging select highquality FRP pultrusion profiles, the service life of the product can be more than 20 years.

6. Anti-UV agent are added into all pultrusion FRP profiles get the best anti-uv effect.

Product Advantage

1. Coated with prevent aging layer

2. Excellent insulating performance

3. Easy to maintain.

4. High strength.

5. Long service life.

6. Easy to install.

7. Good light transmittance.

Specification

Unit Weight: 1800g/m² 2400g/m² 3050g/m²

Nominal Thickness:0.8mm,1.0mm, 1.2mm 1.5mm 2.0mm, 2.5mm

Heat Resistance Limit: -60 to +130

Light Transmittance: 75%±2% ( light green) 53%±2% (cream white)

Anti- ultraviolet Rate: 99.9%

Tensile Strength: 100Mpa

Flexural Strength: 180Mpa

Cracking Elongation Rate: 1.9%

Pasture Hardness: ≥50

Thermal Expansion Coefficient: 2.2×10¯125px/cm/

Thermal Conductivity: 0.18w/m° k

FAQ

1.Which country do you mainly export to?

A: Our products are very popular in Mid East, India, South East Asia, Latin America, Africa.

2.Q: What’s the advantage of you compared with other suppliers experienced in foreign trade?

A: We have been specialized in FRP products for over decades years and approved by many domestic companies. Except for our quality and price, we’re also able to give you the best service.

3.Q:Can you provide some samples?

A: Yes, of course. We will send you samples for your confirmation before you place firm orders.

.

- Q: Can FRP pultrusion profiles be used in the construction of outdoor signage?

- Certainly, outdoor signage can utilize FRP pultrusion profiles. These profiles possess remarkable qualities, including durability, strength, and the ability to withstand different environmental conditions, rendering them ideal for outdoor use. Typically, these profiles consist of a combination of fiberglass reinforcement and resin matrix, resulting in a lightweight yet robust material. Outdoor signage often confronts harsh weather conditions, such as rain, sun exposure, and temperature fluctuations. FRP pultrusion profiles exhibit excellent resistance to corrosion, UV rays, and moisture, ensuring that the signage retains its structural integrity and visual appeal over time. Moreover, FRP pultrusion profiles offer customization options to fulfill specific design requirements, offering flexibility in creating distinctive and captivating outdoor signage. These profiles can be effortlessly shaped, cut, and assembled, making them a versatile choice for signage applications. In essence, the construction of outdoor signage can undoubtedly benefit from the use of FRP pultrusion profiles due to their durability, resistance to environmental conditions, and design flexibility.

- Q: How do FRP pultrusion profiles handle cyclic loading?

- FRP pultrusion profiles are known for their excellent performance under cyclic loading conditions. The unique combination of materials and manufacturing process used in pultrusion makes these profiles highly resistant to fatigue and cyclic loading effects. One key factor that contributes to the superior performance of FRP pultrusion profiles under cyclic loading is their inherent high strength-to-weight ratio. These profiles are made using continuous fibers, typically fiberglass, which are impregnated with a resin matrix. This results in a lightweight yet strong material that can handle repeated loading without experiencing significant degradation or fatigue. Additionally, the pultrusion process allows for precise control over the fiber orientation and resin distribution within the profile. This results in a uniform and consistent material composition throughout the entire length of the profile. As a result, FRP pultrusion profiles exhibit excellent load distribution characteristics, minimizing stress concentrations and preventing localized failure under cyclic loading conditions. Furthermore, the corrosion resistance of FRP pultrusion profiles plays a crucial role in their ability to handle cyclic loading. Unlike traditional materials such as steel, FRP profiles do not suffer from corrosion-related issues, such as rust or pitting. This corrosion resistance ensures that the profiles maintain their structural integrity even when subjected to cyclic loading over extended periods of time. Overall, FRP pultrusion profiles are specifically designed and manufactured to withstand cyclic loading conditions. Their high strength-to-weight ratio, uniform material composition, and corrosion resistance make them ideal for applications where cyclic loading is a significant factor. Whether it's in structural reinforcements, bridges, sporting equipment, or various industrial applications, FRP pultrusion profiles have proven to be reliable and durable under cyclic loading.

- Q: What is the compression strength of FRP pultrusion profiles?

- The compression strength of FRP pultrusion profiles can vary due to several factors, including the type of resin, fiber orientation, and design. However, on average, the compression strength of these profiles ranges from 10,000 to 50,000 psi. It is worth mentioning that these values are approximate and may differ depending on the specific application and intended use of the FRP profiles. Moreover, manufacturers usually offer technical data sheets that detail the compression strength and other mechanical properties of their FRP pultrusion products. These sheets can be used to obtain more precise and dependable information.

- Q: How do FRP pultrusion profiles handle cyclic torsion loads?

- FRP pultrusion profiles are designed to handle cyclic torsion loads effectively due to their inherent properties. The continuous fibers in the profiles provide high strength and stiffness, enabling them to withstand repeated twisting without deformation or failure. Additionally, the resin matrix used in the pultrusion process offers excellent fatigue resistance, ensuring long-term durability and performance under cyclic torsion loads.

- Q: Can FRP pultrusion profiles be used in the construction of amusement park rides?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of amusement park rides. FRP pultrusion profiles offer numerous advantages that make them suitable for such applications. Firstly, FRP pultrusion profiles are known for their high strength-to-weight ratio. This means that they are significantly lighter than traditional materials like steel while still maintaining excellent structural integrity. As a result, using FRP profiles in amusement park rides can help reduce the overall weight of the structure without compromising on safety. Secondly, FRP pultrusion profiles have excellent corrosion resistance properties. Unlike steel, FRP does not rust or deteriorate when exposed to moisture or chemicals commonly found in amusement park environments. This makes FRP profiles ideal for rides that are constantly exposed to water, humidity, and other harsh conditions. Additionally, FRP pultrusion profiles offer design flexibility. They can be manufactured in various shapes and sizes, allowing for customized designs to meet specific requirements of amusement park rides. This versatility in design enables engineers and designers to create complex and intricate structures that are both aesthetically pleasing and functional. Moreover, FRP pultrusion profiles have excellent electrical insulation properties. This is particularly important for amusement park rides that may have electrical components and wiring, as FRP profiles can provide a high level of safety by preventing electrical conductivity. Furthermore, FRP profiles are non-magnetic, which can be advantageous in amusement park rides that use magnetic systems or sensors. Non-magnetic materials eliminate the risk of interference or disruption to the ride's functionality. Lastly, FRP pultrusion profiles are durable and require minimal maintenance. They are resistant to UV radiation, which means they will not degrade or fade due to prolonged exposure to sunlight. This reduces the need for frequent painting or coating, resulting in lower maintenance costs over time. Overall, the combination of lightweight, corrosion resistance, design flexibility, electrical insulation, non-magnetic properties, and durability make FRP pultrusion profiles an excellent choice for the construction of amusement park rides.

- Q: Are FRP pultrusion profiles resistant to fire?

- Yes, FRP pultrusion profiles are inherently fire resistant. The combination of the polymer matrix and the reinforcing fibers used in the pultrusion process provides excellent fire resistance properties, making them a suitable choice for applications where fire safety is a concern.

- Q: Are FRP pultrusion profiles resistant to oil and grease?

- FRP (Fiber Reinforced Plastic) pultrusion profiles are generally known for their excellent resistance to oil and grease. The combination of fibers, typically glass or carbon, with a polymer resin matrix results in a material that is inherently resistant to many chemicals, including oil and grease. This resistance is attributed to the non-reactive nature of the polymer resin, which prevents the oil or grease from penetrating the material and causing damage. Additionally, the pultrusion manufacturing process used to produce FRP profiles further enhances their resistance to oil and grease. During the pultrusion process, the fibers are impregnated with the resin and then pulled through a heated die, where the resin is cured. This creates a strong, uniform material with a dense surface that is less porous and more resistant to chemical penetration. It is important to note that the specific resistance of FRP pultrusion profiles to oil and grease can vary depending on the type of resin used and the specific application conditions. In some cases, specialized resin formulations can be used to further enhance the oil and grease resistance of FRP profiles, ensuring suitability for even more demanding environments. Overall, FRP pultrusion profiles are generally considered to be highly resistant to oil and grease, making them an excellent choice for applications where exposure to these substances is expected. However, it is always recommended to consult with the manufacturer or supplier to ensure that the specific FRP profile being used is appropriate for the intended application and chemical exposure.

- Q: Are FRP pultrusion profiles resistant to termites?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to termites. Termites primarily feed on cellulose-based materials, such as wood, and since FRP pultrusion profiles are made of a combination of resin and glass fibers, they do not contain cellulose and therefore are not attractive to termites. This makes FRP pultrusion profiles a great alternative to traditional wooden profiles when it comes to applications where termite resistance is required, such as in building construction and outdoor structures. Additionally, FRP profiles are also resistant to rot, corrosion, and other environmental factors, making them a durable and long-lasting material choice.

- Q: Can FRP pultrusion profiles be used in the construction of solar panel frames?

- FRP pultrusion profiles are a viable option for constructing solar panel frames. These profiles possess qualities such as being lightweight, strong, and corrosion-resistant, making them an ideal material choice. Their durability and high strength-to-weight ratio ensure that the frames can withstand different weather conditions and prolonged exposure to sunlight. Moreover, FRP pultrusion profiles can be easily customized to meet specific design requirements, providing flexibility in solar panel frame construction. All in all, utilizing FRP pultrusion profiles in this industry offers multiple benefits, making it a suitable choice for the solar energy sector.

- Q: Can FRP pultrusion profiles be used in the construction of pedestrian tunnels?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of pedestrian tunnels. FRP is a lightweight and high-strength material that offers numerous advantages over traditional construction materials like steel or concrete. One of the main advantages of using FRP pultrusion profiles in the construction of pedestrian tunnels is their corrosion resistance. Unlike steel, FRP does not corrode when exposed to moisture or harsh environmental conditions. This makes FRP profiles ideal for underground structures such as pedestrian tunnels where water seepage or high humidity can be a concern. Additionally, FRP pultrusion profiles have excellent mechanical properties, including high tensile strength and stiffness. This allows them to withstand heavy loads and provide structural integrity to the tunnel. The lightweight nature of FRP also makes it easier to handle and install, reducing the construction time and costs. Furthermore, FRP profiles can be easily molded into various shapes and sizes, making them highly versatile for designing pedestrian tunnels. They can be customized to meet specific project requirements, such as the curvature or dimensions of the tunnel. This flexibility in design allows for creative and efficient solutions in tunnel construction. In terms of safety, FRP pultrusion profiles have a high fire resistance and are non-conductive, which is crucial in ensuring the safety of pedestrians in tunnels. They also have a low thermal conductivity, providing insulation properties that can help maintain a comfortable environment inside the tunnel. Overall, the use of FRP pultrusion profiles in the construction of pedestrian tunnels offers numerous benefits, including corrosion resistance, high strength, versatility in design, and improved safety. These advantages make FRP an excellent choice for constructing durable and efficient pedestrian tunnels.

Send your message to us

FIBER REINFORCE PLASTIC PANEL/ROOFING SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords