High Strength Composite Materials AR Glass Fiber Roving

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000Kgs m.t.

- Supply Capability:

- 100000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High strength composite materails AR Glassfiber roving

AR glassfiber is one kind of concrete fiber used for spary up or mechanical continuous formed GRC, such as formwork roof board, decoration panel, garden feature. It has widely used in tunnel, mine shaft, protect slop, spray-up roving for reinforcement surface and tip of wall.

Alkali-resistant(AR) fiberglass is the base material to make Fiberglass Reinforced Cement (GRC), which has been widely used in building industry as board, corrugated proofing sheet, division panel, internal and external insulation panel, decorative panel, dust panel, cable box, granary, channels drainage and garden furniture, artistic sculpture, etc.

Products Features and Advantages

1) Excellent chopped performance and dispersion.

2) Fast and complete wet-out.

3) Low static, no fuzz.

4) Easy roll-out and air release.

5) High mechanical strength.

Technical Data of high strength composite materials Ar glass fiber roving:

PRODUCT NAME | AR- FIBERGLASS CHOPPED STRAND | |||

TEST CRITERION | JC/T572-2002 | |||

TEST ITEM | METERAGE UNIT | STANDARD | RESULT | CONCLUSION |

ZRO2CONTENT | % | ≥16.5 | 16.7 | MEASURE UP |

MOISTURE CONTENT | % | ≤0.2 | 0.1 | MEASURE UP |

TENSILEBREAKING STRENGTH | N/TEX | ≥0.25 | 0.3 | MEASURE UP |

CHOPPED LENGTH | MM | 12±1 | 12 | MEASURE UP |

LINEAR DENSITY | TEX | 98±8 | 99 | MEASURE UP |

COMBUSTIBLE MATTER CONTENT | % | 0.8-2.0 | 1.48 | MEASURE UP |

CONCLUSION | IN CONPLIANCE WITH JC/T572-2002 | |||

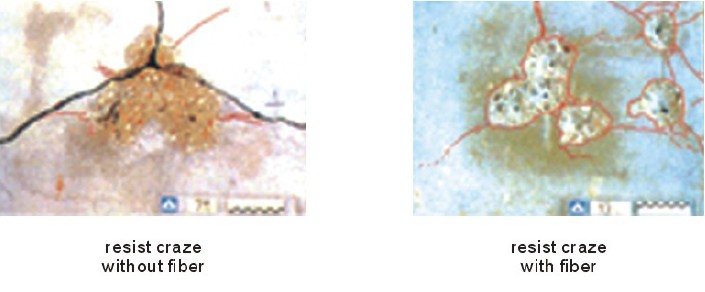

Crack Test:

Packing Style

Each bobbin is 18±1kgs and wrapped by a PVC shrink bag. If required, each bobbin could be packed into a suitable cardboard box.

Each pallet contains 3 or 4 layers, and each layer contains 16 bobbins(4x4). The bobbins in the pallet could be singly piled or be connected as start to end by air spliced or by manual knots.

The whole pallets of bobbins are wrapped with cardboard boxes, packed on the pallet with packing straps and shrink film or with multi-layers of shrink film only.

Storage

This product should be stocked in dry and cool places. The best condition is with temperature between 15 and 35°C, with a relative humidity between 30%-70%. Please keep the product in its original packing before using, avoid moisture.

- Q: What is better brick patio or cement patio(ie cleaning it,cost)?

- Cement cracks,bricks do not.I have seen far too many embossed cement patios crack in the last five years.

- Q: BP is currently pumping great quantities of mud into the rupture in the Gulf and plan to dump cement in when the flow permits. Cement has to dry to be effective? So how does it dry under water and the pressures it will encounter at that depth.

- it doesn't dry; it sets - it's a chemical reaction; not simply evaporating its water content. Setting time depends on the exact chemical mix of the cement - unsurprisingly, fast-drying cement sets very quickly but is usually comparatively brittle, while slower formulations take longer but tend to be stronger. Considerable heat is given off during the setting process and the cement tends to expand, particularly if too much is added at once so that the heat in the middle can't dissipate quickly enough - this is another reason why slow-setting is preferred in many situations. Setting is also speeded up by spraying with water which not only aids the chemical reaction but also helps in cooling. Under the sea the water would actually assist in the setting process. The main problem is that it will be subjected to the pressure of the escaping oil while setting which will reduce its strength - this is probably why they're also pumping mud into the hole - this will partially clog up the hole and reduce the pressure and so give the cement a better chance of working.

- Q: How is cement made and what is in it?

- I worked at a cement factory in Humboldt Kansas . I was an electrician. There are different kinds of cement .Mort-er , and all kinds of mixes .It was very hot there .They had a kilm . They had a smoke stack that was hot enough to burn tires . So they did . I don't know what all goes into cement .I do know it is very dry and water just beads up on top of it and doesn't soak in till you agitate it.

- Q: Portland cement compared with slag cement Thank you for the exam! More

- Slag cement is greater than that of Portland cement.

- Q: Tableware kitchen, epoxy resin can? Specific paint name and processing process, thanks for the

- Cement board is a cement as the main raw material processing and production of a building plate, is a between the gypsum board and stone, free cutting, drilling, carving of the building products, with its superior to gypsum board, wood fire , Waterproof, anti-corrosion, pest control, sound insulation and far lower than the price of stone and become the construction industry widely used in building materials

- Q: Someone I hired to do my walkway used cement to rentrain the pavers edge, instead of edge restrainters. I found it very strange. I even pointed it out to him. He said it ok. Who am i do defy an experient brazilian mason.The cement is now cracking. My brand new walkway will not make thru the winter. I have already started my complain process.

- Actually, you mean concrete, not cement. Should be fine, it's done all the time. What are the dimensions? He may have mixed the concrete improperly (wrong ratio or too wet). We need more info. about the whole installation-soil, slope, drainage, radius if it's curved, etc.. A photo would be really helpful.

- Q: what is the difference between refractory cement and furnace cement?

- Furnace cement is a finer grit meant for patching up seams to make them air tight. Refractory cement is for the cast concrete structures themselves.

- Q: I need some rubber cement thinner but dont want to pay the outrageous amount being asked for my local arts n crafts store. Is there something than can be obtained cheaper at my local home goods place that will do the same job?

- Lighter fluid would probably work.

- Q: how many cubic meters of cement are there in a 40 kgs. (94lbs) bag of portland cement?

- The Specific Gravity of Portland Cement is 3.15 so there are 0.0127m3 of Portland cement in a 40kg bag measured as a solid. As the density of the cement in the bag is about 1506kg/m3 (allowing for the voids between the grains) the volume of a 40kg bag is about 0.0266m3

- Q: is it possible to make my pvc cement quot;normalquot; again... because now its all dry...

- You would be better off to buy some new stuff, but there is a remote possibility you can make it glue again by mixing some acetone in to it, but, but , but the acetone is more expensive than buying new pvc cement. So the moral of this story is; buy new pvc cement and get used to the idea that the stuff will dry out with some regularity. Actually eventually it all dries out even if you are careful to close the can very tight. It is a universal truth in life. I wish I had $5.00 for every can of that stuff that has gotten hard on me.

1. Manufacturer Overview

| Location | Shanxi, China |

| Year Established | 1982 |

| Annual Output Value | Above US$ 30 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai Port, China |

| Export Percentage | 41-50% |

| No.of Employees in Trade Department | 20-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

High Strength Composite Materials AR Glass Fiber Roving

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000Kgs m.t.

- Supply Capability:

- 100000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords