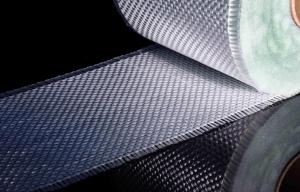

AR Fiberglass/Glass Fiber roving

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000Kgs m.t.

- Supply Capability:

- 100000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

ar fiberglass roving

1.Easy chopped

2.Good integrity and dispersibility

3. alkali resistant

4. excellnt durabilty

alkali resistant continuous roving ar glass fiber roving

1. Ar fiberglass roving

AR glass gun roving is mainly designed for use in the manufacture of GRC composites by the manual spray method. It is designed for optimum processability. It is used in the manufacture of GRC architectural panels and other building elements, civil engineering and infrastructure components.

PRODUCT NAME | AR GLASSFIBER SPRAY ROVING | |||

TEST CRITERION | JC/T 572-2002 | |||

TEST ITEM | METERAGE UNIT | STANDARD | RESULT | CONCLUSION |

ZrO2 CONTENT | % | ≥16.0 | 16.7 | MEASURE UP |

FILAMENT DIA | μM | 13±2 | 13 | MEASURE UP |

STRAND TEX | TEX | 2700±270 | 2720 | MEASURE UP |

BREAKING STRENGTH | N/TEX | ≥0.25 | 0.32 | MEASURE UP |

MOISTURE CONTENT | % | ≤0.2 | 0.11 | MEASURE UP |

COMBUSTIBLE CONTENT | % | 0.8~2.0 | 1.68 | MEASURE UP |

STIFFNESS | MM | ≥120 | 170 | MEASURE UP |

CONCLUSION | IN CONPLIANCE WITH JC/T 572-2002 | |||

2. Pallet Packing

1) Each pallet has 3 or 4 levels ,16rolls /level.

2) The complete pallet is enclosed in polythene and identified with two labels.

Product | Level per pallet | Total number of cheese | Pallet | |||

Length(mm) | Width(mm) | Height(mm) | Net weight(kg) | |||

ARC15-2400L | 3 | 48 | 1130 | 1130 | 1000 | 860 |

3 | 48 | 1130 | 1130 | 1000 | 1000 | |

4 | 64 | 1130 | 1130 | 1300 | 1150 | |

Shipment

For sea transport, a maximum of 20 pallets (on two levels) may be loaded in a 20 foot container, giving a total net weight of approximately 17-20 tonnes.

3. Storage

AR GLASSFIBRE SPRAY ROVING should be stored dry in their original packaging, the best conditions being at a temperature of between 15°C-35°C and at a relative humidity of between 35% - 65%. If the product is stored at low temperature (below 15°C) it is advisable to condition in the workshop for 24 hours before use to prevent condensation.

4. Production flow chart

- Q: So not too long ago I got a permanent retainer glued to the top of my teeth. My sister told me that her permanent retainer once fell off and it got me paranoid. I just go it on so the cement is relatively fresh but I rub the glue with my tongue and now I have a question... How strong is the cement? Can I eat and drink whatever or will certain foods and drinks ruin and wear the glue away? Should I brush and floss there gentler as to not wear the glue away? I hear all these stories of where the glue sometimes falls off in little chunks or something and they have to get their retainer re-glued on and so I ask how long will the glue last on my teeth before it starts to fade? Is the cement/glue strong enough to last awhile? Etc.

- Whether or not it comes off is dependent on two things, really: 1: you not eating dumb things, like gum or air heads, etc. and 2: your bite. Some just do. The glue will stay as long as the bond took. Some may chip off from your bite, but there's not a lot you can do aside from being careful to stay away from foods that you are not supposed to eat. The glue can last years and years. It's the same stuff we use to cement crowns and it lasts decades. But adults don't do the same dumb stuff with their mouths that kids do.

- Q: I need to glue a small plastic piece to another plastic piece, will the cement work? What are the steps in gluing and making sure the glue holds?

- Barge Cement

- Q: I spray painted a lamp in my garage and now i have a circle on the cement. How do i get it off with out using one of those power spayers?

- sand blasting will do the trick - all else, there are chemicals that can be purchased @ lowe's , home depot etc under graffitii removal.. that will work - i would try these places -

- Q: what is the ratio for the cement to install cement block; sand, cement . and mortor creme?

- There is a difference in the sand for motar that the sand you use for pouring cement such as a slab. The motar sand is very, very fine and for the cement you can just use builders sand. I recommend a 3 to 1 mixture. Not sure what you mean by motar creme unless you are referring to a latex additive. I would absolutely recommend using the additive, it makes the motar more of an adhesive and also makes it repel moisture so it will last years longer especially in colder climates.

- Q: i'm replacing the old wall in my tub with hardibacker. can i screw it on the tub lip? coz the instructions said that it should be screwed or nailed 3/8quot; from the eges.

- Just give loving the 10 points and take his advice. Steven Wolf

- Q: what are the properties of cement and water?

- cement consist of Oxides and water forms hydrates of these oxides

- Q: This crack has caused a layer of cement wall, about 1/2 inch thick, to fall off. The area of the layer that has come off is about 1ft by 1ft. Do I need to add cement to the wall to fix it? My house is a 1920-40 era colonial so the house is pretty old. The basement wasn't finished, but there was drywall on the wall where the crack was. I removed the wall because of water damage and I found the crack. I am not going to finish the basement, I just want to waterproof the wall, paint it and have the exposed concrete. I plan on doing this myself if it is possible. Additionally I found some thin roots in the wall where the 1/2in layer of concrete came off. Should I be worried about that? Thanks in advance.

- Go to Lowes and check out the hydraulic cement, and see if this would work for you....you will have to find the source of the roots and get rid of the roots...since it is leaking, the hydraulic cement will get harder with moisture, you can do a web search and see if you think this product would work to solve your problem, Good Luck

- Q: I've had braces and had a permanent lower retainer put in. Well the dentist removed it today and never scrapped the cement off of the back of my teeth. Anyone know of a way that I can get it off at home without having to go back to the dentist?

- You can't really get it off yourself. You need to go back to your orthodontist and have him do it. He must have forgotten to take it off. Usually they do a good job of removing the stuff.

- Q: What percent of garnet is in cement?

- There shouldn't be any garnet in cement. Portland cement (the most common one) is a mixture of roasted limestone, clay and gypsum. None of these rocks normally contain garnets.

- Q: There is water that seeps in when it rains hard near a pipe where the city water comes in. I already tried to use quot;Great Stuffquot; around the pipe and it didn't work. Do I just put hydraulic cement in the area around the pipe area, or do I have to do the whole wall? (Can you tell I'm a new homeowner?)

- To answer the question with certainty a few details may be needed--- where the water line comes in how many feet below grade is it-- if close to grade then re-grading the property around the water pipe may solve the problem-- re-grading away from the house will cause the rainwater to flow away from the house wall--if it is say more than 4 feet below grade-- using hydraulic cement from the inside may be a temporary fix but the outside water pressure will force it out of the crack/hole after 1-2 years depending on how severe your cold/frost cycles are in your neck of the woods-- most water mains that I have seen come up through the floor of most homes--if you are certain the water line entry is leaking dig down from the outside to said water line and apply the cement-a rubber membrane- some tar product--like roofing material sealer and another rubber membrane-- best of luck--

1. Manufacturer Overview

| Location | Shanxi, China |

| Year Established | 1982 |

| Annual Output Value | Above US$ 30 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai Port, China |

| Export Percentage | 41-50% |

| No.of Employees in Trade Department | 20-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

AR Fiberglass/Glass Fiber roving

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000Kgs m.t.

- Supply Capability:

- 100000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords