Glass Roving (High Strength Roving) Fiberglass Roving

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Glass Roving (High Strength Roving) Fiberglass Roving

Introduction:

Direct Roving is coated with a silane-based sizing and compatible with unsaturated resin, vinyl resin, and epoxy resin. It is designed for filament winding, pultrusion, and weaving applications.

Direct Roving is suitable for use in pipes, pressure vessels, gratings, and profiles, and the woven roving converted from it is used in boats and chemical storage tanks.

Product Features:

1.Resistant to ozone, oxygen, light and climate change.

2.High strength, high modulus, low shrink, no deformation.

3.Incombustible. heat insulation, heat preservation.

4.Hgher than working temperature, still keep residual strength.

5.Corrosion resistance.

6.Electrical insulation.

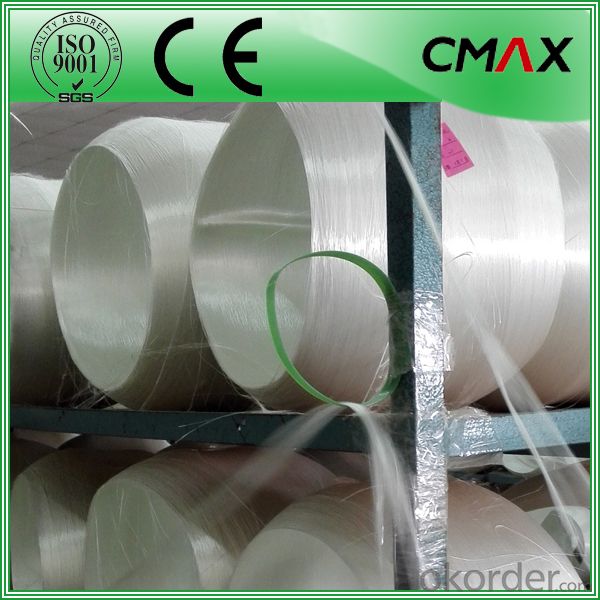

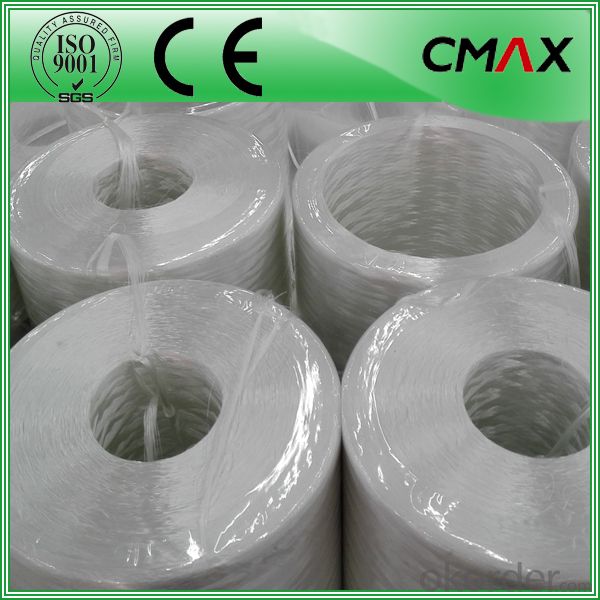

Packaging:

Product is manufactured in form of a roll wrap on a paper tube then after packed in a plastic bag and placed in a cardboard carton. Rolls can be loaded in a container directly or on pallets.

Deposited:

Chopped Strand Mat should be stored in dry, cool, clean and rainproof area. Recommended temperature range of storage is between 15-30 and relative humidity between 40%-70%.

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton

4.Which knid of payment terms can you accept?

We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

- Q: Can fiberglass mat tissue be used for insulation in oil refineries?

- Yes, fiberglass mat tissue can be used for insulation in oil refineries. It is commonly used due to its excellent thermal insulation properties, resistance to high temperatures, and resistance to chemical corrosion.

- Q: Can fiberglass mat tissue be used for wind turbine nacelles?

- Yes, fiberglass mat tissue can be used for wind turbine nacelles. Fiberglass mat tissue is a lightweight and durable material that is commonly used in various industries, including wind energy. It is highly suitable for wind turbine nacelles due to its excellent mechanical properties, such as high strength, stiffness, and resistance to corrosion and fatigue. Additionally, fiberglass mat tissue can be easily molded into complex shapes, making it ideal for fabricating the intricate components of wind turbine nacelles. Overall, using fiberglass mat tissue in wind turbine nacelles helps to enhance their structural integrity, reduce weight, and improve the overall performance and longevity of the turbines.

- Q: Can fiberglass mat tissue be used for pipe wrapping?

- Yes, fiberglass mat tissue can be used for pipe wrapping. Fiberglass mat tissue is a lightweight and flexible material that is commonly used for reinforcing and protecting various structures, including pipes. It is designed to provide strength and durability to the pipes, making them more resistant to damage and corrosion. The fiberglass mat tissue can be easily wrapped around the pipe, creating a protective layer that helps to prevent leaks and extend the lifespan of the pipe. Additionally, fiberglass mat tissue is also known for its excellent insulation properties, which can help to maintain the temperature of the contents flowing through the pipe. Overall, fiberglass mat tissue is a suitable material for pipe wrapping and is commonly used in various industries for this purpose.

- Q: Is fiberglass mat tissue suitable for railway infrastructure?

- Yes, fiberglass mat tissue is suitable for railway infrastructure. It is a versatile material that offers excellent mechanical strength, durability, and corrosion resistance. It can be used for various applications in railway infrastructure, including reinforcement of concrete structures, insulation, and protection against fire hazards. Additionally, fiberglass mat tissue is lightweight and easy to install, making it a cost-effective choice for railway projects.

- Q: Can fiberglass mat tissue be used for bridge construction?

- Bridge construction can indeed utilize fiberglass mat tissue. This adaptable material provides numerous benefits. Its lightweight nature and impressive strength make it ideal for bridges, especially when weight is a key consideration. Moreover, fiberglass mat tissue boasts exceptional durability and corrosion resistance, essential for maintaining bridges' longevity. Its malleability allows for flexible bridge designs, as it can be easily molded into different shapes. In addition, fiberglass mat tissue possesses excellent impact resistance and fatigue performance, guaranteeing the bridge's ability to withstand heavy loads and constant traffic. All in all, fiberglass mat tissue represents a dependable and cost-effective option for bridge construction.

- Q: Does fiberglass mat tissue require any special surface treatments before application?

- Special surface treatments are necessary before applying fiberglass mat tissue in order to ensure proper adhesion and bonding with the substrate. Applying a primer or bonding agent is a common treatment that enhances the bond strength between the fiberglass mat tissue and the substrate. Typically, the primer or bonding agent is applied to the substrate and allowed to dry before applying the fiberglass mat tissue. Another treatment involves removing any loose or flaking material from the substrate's surface. This can be achieved through mechanical methods like sanding or grinding, or by using a chemical treatment to dissolve or eliminate unwanted material. This step is crucial to establish a clean and smooth surface for the fiberglass mat tissue to adhere to. In certain cases, it may be necessary to roughen or etch the substrate's surface to provide a better bonding surface for the fiberglass mat tissue. The method used for roughening or etching depends on the type of substrate being used and can involve abrasives or chemical etching agents. The specific surface treatment required for fiberglass mat tissue depends on factors such as the type of substrate, desired bond strength, and application method. Following the manufacturer's instructions and recommendations for surface preparation is essential to achieve a successful application and long-lasting bond.

- Q: How does fiberglass mat tissue perform in terms of mold and mildew resistance?

- Fiberglass mat tissue generally performs well in terms of mold and mildew resistance. The material's non-porous nature and moisture resistance help inhibit the growth of mold and mildew. Additionally, fiberglass mat tissue is often treated with anti-fungal agents during the manufacturing process, further enhancing its resistance to mold and mildew. However, it is important to note that proper installation and maintenance are crucial to ensure optimal mold and mildew resistance.

- Q: Can fiberglass mat tissue be used for attic insulation?

- Typically, fiberglass mat tissue is not the primary insulation material used in attics. Its purpose is to complement other insulation materials, like fiberglass batts or blown-in insulation, in order to enhance their performance and provide some thermal resistance. Fiberglass mat tissue is frequently utilized as a facing material for insulation products, serving as a vapor barrier or a reinforcement layer. Although it can enhance the durability and moisture resistance of the insulation, its main function is not to offer significant thermal insulation on its own. When insulating an attic, it is more common to employ materials specifically designed for thermal insulation, such as fiberglass batts, cellulose, or spray foam insulation. These materials possess higher R-values and are more effective at minimizing heat transfer, which is essential for maintaining a comfortable indoor temperature and achieving energy efficiency. In conclusion, fiberglass mat tissue may possess insulation properties, but its primary purpose is to enhance the performance of other insulation materials rather than being used as the sole insulation in an attic.

- Q: How is fiberglass mat tissue used in the production of chemical storage tanks?

- Fiberglass mat tissue is utilized in the production of chemical storage tanks as a reinforcement material. It is typically combined with resin to form a composite material that provides strength, durability, and resistance to various chemicals. The fiberglass mat tissue is layered within the tank structure to enhance its structural integrity and prevent leakage. During the manufacturing process, the fiberglass mat tissue is impregnated with resin, usually polyester or epoxy, to create a strong bond between the fibers and the matrix. This impregnated mat is then placed on a mold or mandrel and subsequently covered with additional layers of resin and mat, forming a laminate. The number of layers and thickness can vary depending on the desired tank specifications and the chemicals it will store. The combination of the fiberglass mat tissue and resin provides excellent corrosion resistance, making it suitable for storing a wide range of chemicals. Fiberglass is inherently non-reactive and can withstand exposure to harsh chemicals, acids, and alkalis without degrading or compromising the tank's structural integrity. This makes fiberglass mat tissue a preferred material for chemical storage tanks, as it ensures the safety of the stored chemicals and minimizes the risk of leaks or contamination. Additionally, the use of fiberglass mat tissue allows for the production of tanks with complex shapes and sizes, as it can be easily molded and formed into various configurations. This flexibility in design ensures that chemical storage tanks can be tailored to specific requirements and can be efficiently integrated into different industrial applications. In summary, fiberglass mat tissue plays a crucial role in the production of chemical storage tanks by reinforcing the tank structure, providing resistance to chemicals, and enabling the fabrication of tanks with diverse shapes and sizes. Its combination with resin creates a durable and corrosion-resistant composite material, ensuring the safe storage of chemicals in various industrial settings.

- Q: Can fiberglass mat tissue be used for insulating ductwork?

- Indeed, insulating ductwork can be accomplished by employing fiberglass mat tissue. This insulation material is characterized by its composition of delicate glass fibers. Its lightweight and pliable nature facilitate effortless installation around ductwork, ensuring optimal thermal insulation. The outstanding insulating qualities of fiberglass mat tissue serve to minimize heat loss or gain within ducts, effectively enhancing energy efficiency. Additionally, it aids in condensation reduction and noise attenuation. Furthermore, its resistance to moisture, fire, and pests renders fiberglass mat tissue a fitting option for insulating ductwork in diverse environments.

Send your message to us

Glass Roving (High Strength Roving) Fiberglass Roving

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords