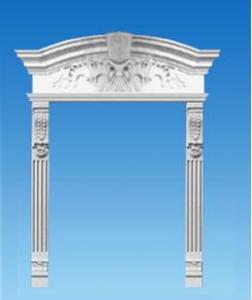

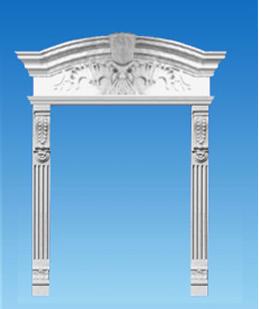

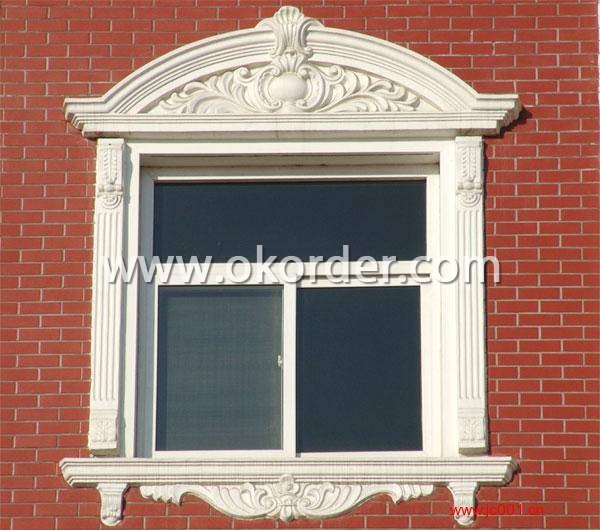

GRC Window Frame Mould For European Style Decoration

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 Sets set

- Supply Capability:

- 3000000 Sets set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction Of GRC Window Frame Mould:

GRC material has excellent constructive performance in history of building construction. With high strength and good nature, it is fireproof, mildew and worm resistant, moisture proof, and sound and heat insulated. It can be processed by nailing, adhering and patching, thus it is easy and convenient in construction.

Description Of GRC Window Frame Mould:

High strengh

Corrosion resistance, anti-frost and waterproof

Natural and hand crafted

Durable

Component Of GRC Window Frame Mould:

Glass Fibre Reinforced Cement(Cement, Alkali Resistant Glass Fibre / protofilament), short for GRC/GFRC

Advantage Of GRC Window Frame Mould:

Strong, Tensile-strength: 1800 Mpa, twice to triple as much as that of steel fibre.

S. G.: 2.7

Durability: Over 10 years

High heat-resistant: Its softening point is about 860

Anti-frost, waterproof&fireproof, mildew&worm and corrosion resistance

UV-protection&environment friendly

Maintenance free

Our advantages

1) -Specialized in this field for more than 15 years

2) -Product quality: strong QC team, strict quality control

3) -Testing report: SGS, ISO 9001:2008, PONY MSDS Report

4) -Received honor: China GRC association member, CCPA council member etc.

5) -OEM/ODM is warmly welcomed

Customer designs are available. Our products are very popular with domestic and abroad market. We have built a steady and long-term cooperation relationships with Chinese top 20 real estate companies and our products are exported to the Middle East, Western Europe, North America, South Africa and other countries and regions.

- Q: I am planning on laying vinyl sheet flooring in my kitchen floor. Can I use cement backer board as an underlayment.

- Cement backer board is for use under tile. I have not seen anyone try to put vinyl over it. I would avoid doing this if I were you. 1/4 luan plywood is common for use underneath vinyl flooring. It provides a smooth, uniform surface to work with.

- Q: the big pieces came from a old cement gold fish pond in my yard .

- best bet sledge hammer easy way eletric jack hammer home depo rents them good luck

- Q: how much is a bag of cement

- for a 96 lb. bag of cement (not concrete) it will be close to 10.00 with the tax...

- Q: Question such as the title, the building which area also used in which aspects of the material? Questions added: What should I pay attention to buying these materials? How can we make money in it? More

- Place is not the same, very different, especially the piece of this piece of wood, sand stone prices worse

- Q: I would like to ask: inside the building materials, often mentioned water-based products, cement-based products What is the meaning? You prawn help solve ~ ~ ~! The The 3Q more

- Cement-based products to cement as the main cement material of building materials products

- Q: im looking to get true blue Jordan cements but i want to know were to get them, and if there is a difference? thanks to everyone! :)

- The only Jordans that have cement are the III's and the IV's (3's and 4's), and only the 3's have a True Blue colorway, so yes, they should be the same. Typically you can find a pair on eBay. I would also suggest staying away from other websites that sell Jordans, as most are typically fake.

- Q: carpet padding on a cement floor whats good?

- Cement floors absorb water from the earth below and if not done properly will result in a soaked carpet and padding (which effectively becomes a sponge). You need to waterproof the cement floor. There is a product that is skimmed/troweled onto the floor to waterproof it, but do not know the manufacturer or product name. (An alternative would be to put a vapor barrier down before the padding). You also need to use the right type of padding on concrete, or use adhesive to adhere your padding or else the carpet will need stretched again before too long. Also, the tack strip should be glued against the walls instead of nailed in, unlike on a wood floor where nails would be used. Tack strips with masonry nails ar OK (just don't use the nail ones for a wood sub-floor).

- Q: know the cement but I want to know the exact definition in engineering view.?

- cement is a cementing material or binding material used in engineering construction. It is manufactured from calcareous substance and is many respects to the strongly limes but possessing far greater hydraulic properties. thanks.

- Q: I recently had my braces removed and while looking in the mirror at my teeth, I noticed black discoloration on several teeth. Is this a common color of the adhesive they use or did my teeth somehow get massive cavities?

- Orthodontic cement is clear hen they out it on and sort of whitish when it dries. So I have no idea what's on your teeth.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2000 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Lianyungang PORT |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 26,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

GRC Window Frame Mould For European Style Decoration

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 Sets set

- Supply Capability:

- 3000000 Sets set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords