High Quality GRC Materials AR Glass Fiber Gun Roving

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000Kgs m.t.

- Supply Capability:

- 100000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High quality GRC materials AR Glass Fiber Gun Roving

is bundle of continuous mono-directional complex basalt fibers. Roving possesses high natural strength, resistance to aggressive environments,long service life and excellent electric insulating properties.By its technical characteristics, Basalt roving surpasses PPTA and UHMWPE fiber by many parameters, and is almost as good as carbon.Basalt roving is extremely heat resistant: long-use temperature range is 200-680 °C. Its tensile strength can reach more than 0.65N/tex, tensile modulus of elasticity hit more than 95Gpa and its breaking elongation is over 2.6%.

Technical Data of High quality GRC materials AR Glass Fiber Gun Roving:

ZrO2 Content | % | JC935-2004 | 14.5±0.8 | 14.8 |

TiO2&ZrO2 Content | % | ≥19.2 | 19.3 | |

Filament dia | um | GB/T7690.5-2001 | 15±2 | 15 |

Strand tex | tex | GB/T7690.1-2001 | 2400±240 | 2460 |

Breaking Strength | N/tex | GB/T7690.3-2001 | ≥0.25 | 0.28 |

Moisture Content | % | GB/T9914.1-2001 | ≤0.2 | 0.09 |

Combustible Content | % | GB/T9914.2-2001 | 0.8-2.0 | 1.35 |

Stiffness | mm | GB/T7690.4-2001 | ≥120 | 150 |

Specific gravity | g/m3 | / | / | 2.7 |

Application of GRC materials AR Glass Fiber Gun Roving

a) Raw material of fabrics and tapes,resistant to alkali, acids and high temperature.

b) Fabrics of needle punching mat.

c) Fabrics of circuit boards.

d) Be well-suited to solutions used for of electrical insulation, dielectric resistance and anticorrosion applications.

e) Tire cord.

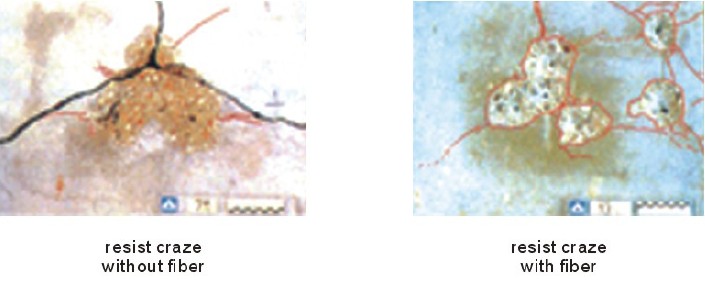

Crack Test:

- Q: It's used for gluing walls for architectural models. What are alternatives for it?

- *Plastic Cement (also known as Poly-Cement) works by melting a plastic surface into another plastic surface, thereby joining them together with a powerful bond. This means it doesn't normally work on metal, but it can be adapted to do so. Refer Standard:ASTM C 1328

- Q: need specification for this type of cement

- Oil well cement can vary depending on the application. Take a look at this link. It has some information on the API specifications that are typically used. You can also get a copy of the specification from API publications.

- Q: I realize it is possible but the only formula I found had gasoline. Are there any other formulas?

- A rubber cement is a mixture of an adhesive and a solvent. The solvent evaporates and leaves behind the adhesive. The most common solvents are n-hexane and n-heptane. You may be able to find the solvents at a larger paint store, especially one that deals with commercial products as opposed to normal consumer products.

- Q: If I scream in a room with wooden walls or cement walls, which one will work better at preventing my sound from reaching outside the room?

- Cement. Wood will vibrate more than cement. Sound is made up of vibrations. I'll leave you to the conclusion.

- Q: How is cement made and what is in it?

- I worked at a cement factory in Humboldt Kansas . I was an electrician. There are different kinds of cement .Mort-er , and all kinds of mixes .It was very hot there .They had a kilm . They had a smoke stack that was hot enough to burn tires . So they did . I don't know what all goes into cement .I do know it is very dry and water just beads up on top of it and doesn't soak in till you agitate it.

- Q: Was there concrete/cement in the 1880s-1890s?

- Uh oh. She forgot the Romans in her History of concrete. Their concrete work is still standing. :) But I liked the story. I know you asked about the 1800's, but if you are also interested in Roman (cementitious) concrete history, here's an interesting site from the University of Santa Barbara: id-archserve.ucsb.edu/arthistory/...

- Q: is there any alternative material for cement?

- in okorder / for more information on house building and decor

- Q: What is Oilfield cement, is it the same as the cement that cars drive on?

- I have never worked in the Oil Patch, but I believe oilfield cement is a mixture of sand, aggregate and a barium compound (barium carbonate, maybe). If you look at the Periodic Table, you will see that barium lies under calcium, and has the same properties (more or less). Since barium is denser, when an over-pressured oil reservoir is breached, this mixture plugs up the drill hole until the well can be capped. This is a major use of the element barium.

- Q: i'm deciding on either white cement 4s 2012, or stealth 3s. i already have military blues but im starting not to like them, however i am not selling them. I reallydnt want another pair of 4s but the white cements are probably one of my favorite jordans. Which should i get?

- Get the white cements

- Q: Should I put an under coat of pva bonding agent then paint over it with weather guard. The cement platser is finished with a wood float so its a little ruff

- I have a cement shed and have found masonry paint to be the only type that will last more than a year or two. Wal-mart has a cheap, good masonry paint that can be tinted any color. I've had cheap Wal-mart masonry paint on my shed for 5 years now and there's no sign of a need to repaint, yet,

1. Manufacturer Overview

| Location | Shanxi, China |

| Year Established | 1982 |

| Annual Output Value | Above US$ 30 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai Port, China |

| Export Percentage | 41-50% |

| No.of Employees in Trade Department | 20-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

High Quality GRC Materials AR Glass Fiber Gun Roving

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000Kgs m.t.

- Supply Capability:

- 100000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords