High Quality Refrigerating Machine Gear Oil pump LB Series

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

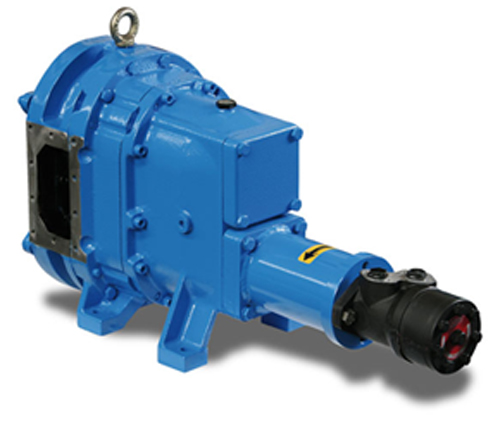

high quality refrigerating machine gear oil pump LB series

Refrigerator gear pump Application

1.be as transfer pump

2.be as booster pump

3.be as fuel pump

4.be as injection pump

5.be as hydraulic pump

6.be as lubricating pump

7.special use refrigerator pump

It is used intransferring N32 of N46refrigerated lubricating and other lubricant oil of ammonia machine or from machine.The suited temperature is 10-800C

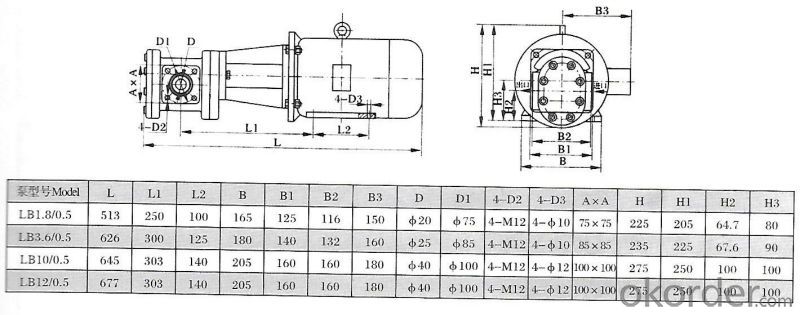

Structural Diagram

Structure

Performance Parameters

| Model | Suction and Extrude Port Diameter(mm) | Capacitym3/h | Differential pressure(Mpa) | Max Differential Pressure(Mpa) |

| LB1.8 | 20 | 1.8 | 0.5 | 2.5 |

| LB3.6 | 25 | 3.6 | 0.5 | 2.5 |

| LB10 | 40 | 10 | 0.5 | 2.5 |

| LB12 | 40 | 12 | 0.5 | 2.5 |

| LB20 | 80 | 20 | 0.5 | 2.5 |

| LB25 | 80 | 25 | 05 | 2.5 |

| LB40 | 100 | 40 | 0.5 | 2.5 |

Note:Pumps above can be matched with different motor as customer's requirement.

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

- Q: What does the pump mortar do?

- In order to effectively reduce the flow resistance of concrete and pipe, to avoid obstruction caused by pipe sticking and to achieve normal pumping, and its role is generally only pumps.

- Q: What are the causes of pump shock?

- 3. the water pump set screws loose, adjust the concentric, fastening the foot4. pump into foreign body, open cover overhaul5. the flow is too large or too small, adjust the equipment to control the water output

- Q: What is the principle of a turbopump?

- A machine that converts the energy contained in a fluid medium into mechanical work [turbine]. Also known as turbines, turbines. Turbine is the transliteration of English turbine, derived from the Latin word "turbo", meaning "rotating object". The working conditions of turbines are different from those of the employed ones, so their structure types are various, but the basic working principle is similar. The most important component of a turbine is a rotating element (rotor or impeller) that is mounted on a turbine shaft and has blades uniformly arranged along the circumference. The energy of the fluid is converted into kinetic energy in the flow through the nozzle, and when the fluid passes through the rotor, the fluid impacts the blade and drives the rotor to rotate, thus driving the turbine shaft to rotate. The turbine shaft drives the other machinery directly or through the transmission mechanism, and outputs mechanical work. According to the turbine working fluid used can be divided into different turbine (used as a power source of Hydropower Station) and steam turbine (used in thermal power plant, ship propulsion), gas turbine (used as jet propulsion, ship power, and power plants, with a small peak load power station and air turbine (only) as a small power).

- Q: What are the starting and stopping procedures for centrifugal pumps?

- The use of centrifugal pump can be divided into three steps, namely, start, run, stop.Start: you should do the following preparation before starting:(1) check the water pump equipment in good condition.(2) the bearings are filled with oil, the oil level is normal, and the oil quality is qualified(3) all the inlet valves of the centrifugal pump are opened.(4) pump water injection or vacuum pump diversion (except for flow), open the vent valve exhaust.(5) check the leakage of shaft seal. It is advisable to fill the seal with a little drop of water.(6) the motor rotates in the right direction.

- Q: How many kinds of pumps are available and the operating principles of various pumps?

- There are many kinds. See what divides.According to the working principle can be divided into: the power type pump, also called pump or impeller vane pump, depending on the dynamic effect of the rotation of the impeller on the liquid, the continuous energy transfer to the liquid, the liquid kinetic energy (mainly) and the pressure will increase, then converting kinetic energy into pressure energy through the discharge chamber, and can be divided into centrifugal pump, axial flow pump, partial flow pump and vortex pump etc..

- Q: Household automatic booster pump, how much pressure to work automatically, the water pressure and how many kilograms?

- With the pressure does not matter, because the pressure is small, it is necessary to boost the pump, the water pressure with the pipe flow and the size of the booster pump related

- Q: Is the flow meter in front of the pump or after the pump?

- After the flowmeter is placed in the pump, it is better to add a pressure tank or a buffer tank, so that the flow meter will work better

- Q: What is an industrial water pump?

- The pump has the different uses, conveying different liquid medium, different flow rate, different lift range, therefore, its structure of course is not the same, the material is different, in general, can be divided into:1, urban water supply 2, sewage system 3, civil and construction systems 4, agricultural water conservancy system 5, power station system6. Chemical system 7, petroleum industry system 8, mine metallurgy system 9, light industry system 10, ship system

- Q: Centrifugal pumps for normal operation, is it reasonable to install valves on their inlet lines? Why?

- Submersible pump is best in the water, if dry pumping will cause burns.

- Q: How to maintain and repair the booster pump of pipeline pump?

- 4. install "0" ring, tighten the pump body and motor end cover with bolts. Notice that the clearance between the front cover of the impeller and the pump body is 20. 0.5 mm. The impeller inlet, the outer ring and the pump body ensure a certain running clearance.5. the disassembly order is the opposite.

Send your message to us

High Quality Refrigerating Machine Gear Oil pump LB Series

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords