Industrial Diesel Driven Water Pump Unit for High Flowrate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

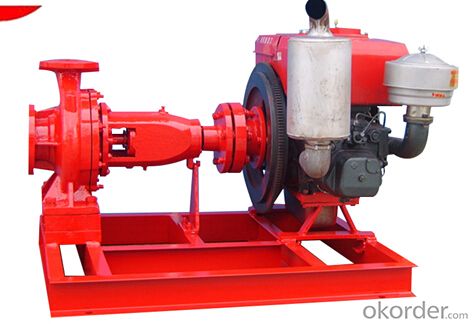

Industrial Diesel Driven Water Pump Unit for High Flowrate

1.Structure of Industrial Diesel Driven Water Pump Unit Description

Diesel Driven Water Pump is used for transporting pure water or liquids with physical and chemical properties similar to pure water, and the maximum of the medium temperature is 80°C.(type ISR pump reaches 120°C). Widely applied towater supply industry, urban water supply and drainage, metallurgy, power stations, textile, chemical industry, printing and dyeing, ceramics, rubber, heating, waste heat utilization, air conditioning, agricultural irrigation and etc.

2.Main Features of the Industrial Diesel Driven Water Pump Unit

• Compact structure, good appearance, low construction

•Operation stably, same inlet and outlet

•Convenient installation and maintenance

•Customized design is available, OEM and ODM are welcomed.

•Horizontally and vertically installation as different pipeline system

3. Industrial Diesel Driven Water Pump Unit images

4. Industrial Diesel Driven Water Pump Unit Specification

Item | Diesel Water Pump |

Diesel Pump | Agricultural Irrigation Desel Water Pump |

Model | IS |

Material | Cast iron |

Mode | Horizontal |

Color | Blue and adjustable |

Theory | Centrifugal Pump |

Structure | Single-stage Pump |

Usage | water |

Power | Electric |

Standard or Nonstandard | Standard |

Fuel | Diesel |

Pressure | High Pressure |

Application | Transporting pure water or liquids |

Outlet Diameter | 32-250mm |

Capacity | 6.3-400m3/h |

Head | 5-125m |

Rotation Speed | 1450-2900r/min |

Power | 0.55-110kW |

Warrenty | 1 Year |

Certificate | ISO9001 |

Feature | High efficiency,Easy maintenance |

5.FAQ

① What is your product range?

Centrifugal pump, slurry pump, gravel pump, clean water pump, sewage pump, chemical pump, single stage

pump, double suction pump, industry pump, oil pump, paper pulp pump, mud pump, self-priming pump, pipe

water pump, boiler water pump, etc.

② Are you a manufacturer?

Yes, we have been in manufacturing and marketing industry centrifugal pump over 20 years.

③ What information should I let you know if I want to get a quotation?

Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please also

provide the pump model you are using now, price will be calculated as per the pump model, if not, we willrecommend relevant product for reference.

- Q: Piston filling and peristaltic pump filling which precision is high?

- First of all, we should know the working principle of each, and analyze the accuracy from the principle, this problem is very important. Piston filling, such as the injection of drugs that we have been ill, the accuracy of the piston pump depends on the accuracy of the motor and the area of the unit cross section

- Q: What is a gear pump for?

- Gear oil pump is through a pair of parameters and the same structure of the involute gear of each other rolling meshing, the tank of low pressure oil to work can do the important parts of high pressure oil. A power unit that converts the mechanical energy of an engine into hydraulic energy. The engine is prone to the following faults during its use.

- Q: What is the pump lift voltage? And how to suppress the pumping voltage rise?

- [suppression of pumping voltage] the general use of the installation of absorption resistance to absorb the pump voltage rise. The simplest way to control the pump voltage is to connect the DC bus with an energy consumption resistor before releasing the pump voltage.

- Q: If the suction pump does not have enough suction range, you need to add a vacuum pump to increase the suction stroke. How do you install the suction pipe of the vacuum pump? Water pump impeller is not closed, it is normal that the vacuum pump is unable to pump suction pipe to a vacuum, is it because the water pump outlet pipe connected to the role of the check valve? But the water pump, outlet pipe, check valve sealing performance can achieve the function of non leakage?

- The role of the check valve:"[the water pump impeller is not closed" refers to the pump suction pump before the water without water inlet pipe and water outlet pipe gas should be connected] is a connector, a connector, still can make the level surface, in order to prevent the water flow along the pipe, until it reaches the level of the flush, then increased check valve, or pumping up water will not leak?Vacuum suction principle of self suction pump:Assuming that the pump connected with the water inlet of a sealed container, the container has plenty of water, since the start of a water pump, water is thrown out of the water impeller pump body, water inlet seal vessel due to the extraction of water to form a vacuum cavity, this assumption will be connected to vacuum cavity and exposed to atmospheric conditions of water, water at atmospheric pressure under the effect of entry into the vacuum chamber".....

- Q: What does the pump mortar do?

- 1: 2 cement mortar or cement mortar with the same proportion of other components except coarse aggregate in the concrete, the pump piston and the inner wall of the pipeline are fully lubricated, and a layer of lubricating film is formed

- Q: How many millimeters is the diameter of the water outlet of the four inch pump?

- This question is of no practical significance. The user does not care about this figure. The concern should be the nominal diameter, which is fitted with flanges and pipes. Moreover, the pump shell is cast iron, the inside diameter is not processed, and there is no matching parts, there is only one manufacturing size.

- Q: The difference between diaphragm pumps, vacuum pumps and centrifugal pumps

- The diaphragm pump and centrifugal pump refer to the structure of the pump, and the vacuum pump means the use of the pump. There is no comparability between them.Centrifugal is the sign of inertia of an object. As the umbrella turns, water droplets move out of the outer edge of the umbrella and are thrown out. This is what is called centrifugal. Centrifugal pump is designed according to this principle. The high speed rotating impeller blade drives the medium to rotate and is thrown out so as to achieve the purpose of conveying.

- Q: What is the lift of diaphragm pump?

- Tell you: diaphragm pump head is liquid through the pump energy obtained is called lift it, and flow and pump speed, a liquid density is generally 1 kg is 10 meters lift, horizontal pipeline 10 meters 1 meters lift, a 90 degree bend is 1 meters.

- Q: What are the characteristics of a vertical multistage centrifugal pump?

- Vertical multi-stage centrifugal pump is cast iron, the advantage is that the price is cheap, the disadvantage is bulky and power consumption.

- Q: What are the parts of a pump? How do you classify it?I just want to know

- The liquid ring pump: pumping air, the working medium is generally at room temperature water gas lift pump: simple structure of submersible sewage pump: a form of basic principle, performance parameters of centrifugal pump, with it the same. Underwater installation, sound, water cooling condition, screw pump: spiral lower invasion water medium variety formThere are too many kinds of pumps, such as submersible pumps for wells, centrifugal feed pumps, sewage pumps, etc. the submersible pumps are wet, oil immersed, etc.The water pump for automobiles is divided into oil lubrication and grease lubrication,

Send your message to us

Industrial Diesel Driven Water Pump Unit for High Flowrate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords