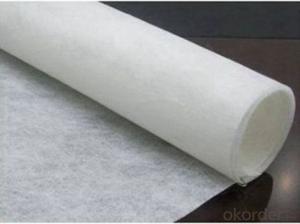

Gs-1 High Quality Non Woven Geotextile Road Building Constructive Felt Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Geotextile has excellent permeability, acquired, durability, which can be widely used in railway ,highway, movement hall,Dams,hydraulic structures hence hole, coastal shoal, reclamation,environmental protection and other projects. The main products are Synthetic staple fibers needle punched nonwoven geotextiles and split film yarn woven geotextiles.

Product introduction:

1.high quality geotextiles

2.CE, ISO9001, ISO14001

3 Sample available

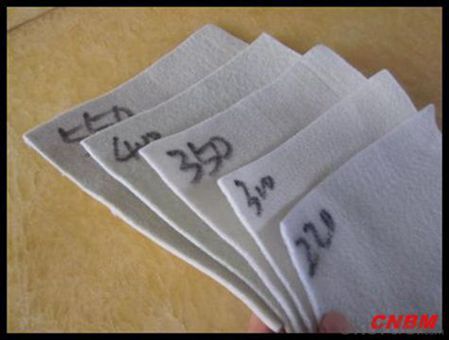

4. 100-800g/m2

Main Export Markets:

Asia

Australasia

Central/South America

Eastern Europe

Mid East/Africa

North America

Western Europe

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geotextiles help with subgrade stabilization?

- Geotextiles help with subgrade stabilization by providing reinforcement and separation between different soil layers. They improve the strength and stability of the subgrade by distributing loads more evenly, preventing the mixing of different soil types, and reducing the potential for settlement and deformation.

- Q: Are geotextiles suitable for use in drainage ditches?

- Yes, geotextiles are suitable for use in drainage ditches. Geotextiles are often used to enhance the performance of drainage systems by providing filtration, separation, and reinforcement. They can help prevent soil erosion, retain fine particles, and improve water flow, making them an effective solution for drainage ditch applications.

- Q: How do geotextiles help with weed control in landscaping projects?

- Geotextiles help with weed control in landscaping projects by acting as a barrier that prevents weed growth. These fabrics are placed beneath the soil or mulch and create a physical barrier that inhibits weed germination and growth. Additionally, geotextiles allow water and nutrients to penetrate the soil, benefiting the desired plants while suppressing weed growth. Overall, geotextiles provide an effective and eco-friendly solution for weed control in landscaping projects.

- Q: 250 grams of two cloth a film 0.8 thick geotextile what price

- 250 grams of two cloth a film 0.8 thick geotextile per square meter between about 10 yuan -13 yuan, the current price is the lowest in recent years.

- Q: Can geotextiles be used in geosynthetic encased columns?

- Yes, geotextiles can be used in geosynthetic encased columns as they provide reinforcement, filtration, and separation functions. They help to improve the stability and performance of these structural elements by enhancing soil confinement and preventing the loss of fine particles.

- Q: What are the specifications for geotextiles in erosion control projects?

- The specifications for geotextiles in erosion control projects typically include factors such as the material type, strength and durability, permeability, and installation requirements. It is important for geotextiles used in erosion control to be made of high-quality materials that can withstand environmental conditions and provide effective soil stabilization. The strength and durability of geotextiles should be capable of withstanding the forces exerted by flowing water and soil particles. Additionally, the permeability of geotextiles should allow for proper water drainage while preventing soil erosion. Proper installation techniques, such as overlap and anchoring, are also important specifications to ensure the geotextiles effectively control erosion.

- Q: What are the limitations of using geotextiles in high-water flow conditions?

- One limitation of using geotextiles in high-water flow conditions is their potential to clog or become blocked with sediment or other debris. This can reduce their effectiveness in filtering water or preventing erosion. Additionally, geotextiles may not be able to withstand the extreme forces exerted by fast-moving water, leading to their failure or displacement. Therefore, it is crucial to carefully consider the flow conditions and choose appropriate geotextiles with sufficient strength and porosity for the specific application.

- Q: What are the key considerations for geotextile installation in seismic retrofitting projects?

- The key considerations for geotextile installation in seismic retrofitting projects include selecting the appropriate type and grade of geotextile based on site conditions, ensuring proper placement and anchoring of the geotextile to provide effective soil stabilization, assessing the potential for liquefaction and designing appropriate measures to mitigate it, considering dynamic forces and ground motion during installation, and conducting regular inspections and monitoring to ensure the geotextile's performance and effectiveness in withstanding seismic events.

- Q: How do geotextiles contribute to soil compaction control?

- Geotextiles contribute to soil compaction control by providing a barrier between the soil and any applied load or traffic. This helps distribute the load more evenly, reducing the pressure on the soil and minimizing compaction. Additionally, geotextiles can improve soil drainage, allowing excess water to flow away, which also helps prevent compaction.

- Q: How do geotextiles help in preventing soil erosion in agricultural fields?

- Geotextiles help in preventing soil erosion in agricultural fields by acting as a barrier between the soil and external forces such as wind and water. They stabilize the soil by reducing surface runoff, preventing sedimentation, and promoting the growth of vegetation. Geotextiles also enhance filtration and drainage, allowing water to flow through while retaining soil particles, thus minimizing the risk of erosion.

Send your message to us

Gs-1 High Quality Non Woven Geotextile Road Building Constructive Felt Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords