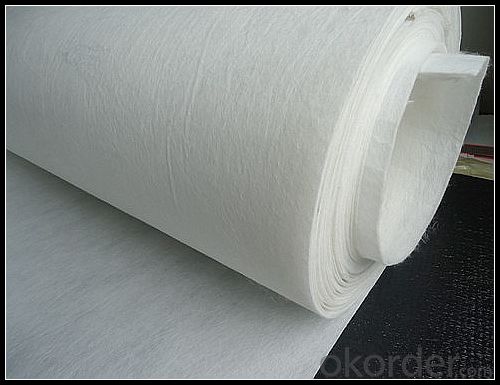

Polyester Geotextile Fabric for Short Non-Woven Geotextile Road Building Constructive Felt Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Non-woven (Filtration and Drainage Fabrics)

Needlepunched polypropylene fiber geotextiles utilized in site drainage, blanket drains and pipe joint wrapping and erosion control under rip rap.

1)Geotextile can make the water flow easily, and form a drainage channel in the soil, and then make the liquid and gas out of the soil.

Make use of its pulling resistance and deformation resistance that can strength the soil to reinforce the stability of the construction structure and improve the soil’s quality.

2) Make the focus proliferate, deliver and decompose efficiently and prevent the soil from destruction from outside factor.

3) Prevent the top and bottom layer’s gravel, soil and concrete from mixer.

4) The mesh cannot be plugged easily – for the strain and moving quality of the network that formed by the antitype fiber.

5) High soaking quality—at the pressure of soil, it also can keep good soaking quality.

6) Corrosion resistant – using the polypropylene and polyester as raw material, it can resist the sour and aid, erosion, boring and oxidation.

Non Woven Geotextile Features:

Wide-width rolls

Quality Certified

Proven for use in Main Roads works

Large range to suit the application

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

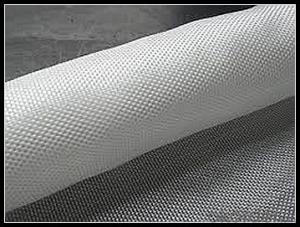

A: Yes, please check the pictures:

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

- Q: How do geotextiles help with weed control in landscaping projects?

- Geotextiles help with weed control in landscaping projects by acting as a barrier that prevents weed growth. These fabrics are placed beneath the soil or mulch and create a physical barrier that inhibits weed germination and growth. Additionally, geotextiles allow water and nutrients to penetrate the soil, benefiting the desired plants while suppressing weed growth. Overall, geotextiles provide an effective and eco-friendly solution for weed control in landscaping projects.

- Q: What is the meaning of the process equipment and equipment for producing geotextiles?

- What is the meaning of the process equipment and equipment for producing geotextiles?

- Q: What are the specifications for geotextiles used in transportation projects?

- Geotextiles used in transportation projects typically have specific specifications in terms of their weight, thickness, tensile strength, permeability, and durability. These specifications ensure that the geotextiles can effectively separate, reinforce, or filter materials in the transportation infrastructure, such as roads, railways, or landfills. Additionally, they must meet certain industry standards and regulations to ensure their effectiveness and longevity in these projects.

- Q: What is the difference between polypropylene geotextile, polypropylene geotextile and polyester geotextile

- Material is not the same

- Q: How do geotextiles contribute to groundwater recharge projects?

- Geotextiles contribute to groundwater recharge projects by acting as a filtration and drainage system. They allow water to pass through while retaining sediment, preventing clogging of the recharge basins or infiltration trenches. This helps to enhance the recharge process, allowing more water to percolate into the ground and replenish the groundwater.

- Q: Do you want to make a geotextile?

- Is not the perforated tube, the cloth is not prevented from blocking the pipe hole. I am specializing in the production of geotextiles may be inside the trench inside the anti-seepage design, laying composite geomembrane

- Q: How do geotextiles contribute to soil stabilization?

- Geotextiles contribute to soil stabilization by providing a barrier that prevents soil erosion, increases soil strength, and improves overall stability.

- Q: Will geotextiles generally use where?

- Water conservancy project dam and slope protection of the filter, channel isolation, anti - seepage. ⒉ road, railway, airport runway foundation isolation, filter, drainage, soil slope, retaining wall and road reinforcement, drainage. ⒊ port engineering soft foundation treatment, beach embankment, harbor wharf and breakwater reinforcement, drainage. ⒋ landfill, thermal power plant ash dam, mine tailings dam isolation, seepage control.

- Q: Geotextile now how much money? what is the price?

- Is to be based on market conditions, raw material prices, processing technology to determine the price of geotextile to Hongxiang Li Qian short wire geotextile, for example, t price is generally between 4900-7500 yuan / ton, but the weight of <200g , An increase of 100 yuan / ton; weight> 800g, an increase of 500 yuan / ton. 187 & lt; 6600 & lt; 5604

- Q: How do geotextiles help in stabilizing slopes for pipeline construction?

- Geotextiles help in stabilizing slopes for pipeline construction by providing reinforcement and erosion control. They are placed along the slope to prevent soil erosion and promote stability. The geotextiles act as a barrier, preventing the movement of soil particles and reducing the risk of slope failure. Additionally, they enhance the soil's strength and increase its resistance to erosion caused by water flow. Overall, geotextiles play a crucial role in maintaining the stability of slopes during pipeline construction.

Send your message to us

Polyester Geotextile Fabric for Short Non-Woven Geotextile Road Building Constructive Felt Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords