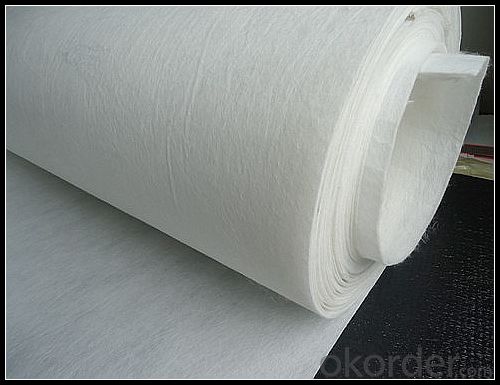

High-Performance Geotextile Grid Road Building Constructive Felt Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Place of Origin:

Shandong, China (Mainland)

Brand Name:

CMAX

Model Number:

CMAX-S001

1.High strength ; low deformation.

2. Durability: steady property, not easy to resolved, airslaked and keep the original property long term.

3. Anti-erosion: anti-acid, anti-alkali, resist insects and mould.

4. Permeability: the woven geotextile can control the sieve size to retain permeability.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

- Q: What are the different functions of geotextiles in geoenvironmental engineering?

- Geotextiles serve various functions in geoenvironmental engineering, including erosion control, soil stabilization, drainage, filtration, and reinforcement. These materials prevent soil erosion by acting as a barrier against water flow and wind forces. They also stabilize soil by improving its mechanical properties, preventing soil movement and settlement. Geotextiles facilitate drainage by allowing water to pass through while retaining soil particles. They serve as a filtration layer, separating different soil layers and preventing the migration of fine particles. Additionally, geotextiles are used for reinforcement purposes, enhancing the strength and load-bearing capacity of soil structures.

- Q: What is the separation between the roof waterproof protective layer and the waterproof layer?

- It is necessary to set the isolation layer to prevent damage to the waterproof layer

- Q: 300g / m2 geotextile package is what it means

- 300g / m2 Geotextile: refers to the weight of 300g per square meter (model) 300g / m2 geotextile package: refers to the outsourcing; with 300g of geotextile to wrap something; for example: With 300g / m2 geotextile wrapped gravel. The

- Q: How do geotextiles contribute to climate change adaptation?

- Geotextiles contribute to climate change adaptation by providing effective solutions for erosion control, slope stabilization, and flood prevention. By reinforcing soil and preventing erosion, geotextiles help to protect vulnerable areas from the impacts of climate change, such as increased rainfall and extreme weather events. They also aid in water management by reducing sediment runoff and improving overall drainage systems. Additionally, geotextiles can be used in the construction of green infrastructure, such as permeable pavements and green roofs, which help mitigate urban heat island effects and improve stormwater management. Overall, geotextiles play a crucial role in enhancing resilience to climate change impacts and promoting sustainable development.

- Q: What are the key considerations for geotextile installation in high-altitude regions?

- When installing geotextiles in high-altitude regions, there are several key considerations to keep in mind. Firstly, the extreme weather conditions typically found in high-altitude areas, such as low temperatures, strong winds, and heavy snowfall, can impact the installation process. Therefore, selecting geotextiles with high durability and resistance to these conditions is crucial. Secondly, proper site preparation becomes even more important in high-altitude regions. The ground should be thoroughly assessed for its stability and potential frost heaving. Adequate measures, such as ground stabilization techniques and proper drainage systems, should be employed to ensure the long-term effectiveness of the geotextile installation. Furthermore, the selection of suitable installation methods is crucial in these regions. The use of specialized equipment and techniques, such as anchoring systems or thermal bonding, may be necessary to counteract the harsh environmental conditions and ensure proper geotextile performance. Lastly, it is essential to consider the environmental impacts of the geotextile installation in high-altitude regions. This includes adhering to local regulations and best practices to minimize disturbance to sensitive ecosystems and wildlife habitats. Overall, key considerations for geotextile installation in high-altitude regions include selecting durable materials, conducting thorough site preparation, using suitable installation methods, and addressing environmental concerns.

- Q: Garden engineering. Do the roof of the hydrophobic board and geotextile roof, would like to know the hydrophobic board and geotextile "sub-project name" and "hidden project"

- Yue Jian professional production geotextile Wang Bin

- Q: How do geotextiles help in preventing differential settlement?

- Geotextiles help in preventing differential settlement by providing additional support and reinforcement to the soil. These permeable fabrics are placed within the soil layers to distribute loads evenly, reduce soil erosion, and enhance stability. By improving soil strength and preventing the differential movement of soil layers, geotextiles help to minimize differential settlement and maintain a more uniform foundation.

- Q: Can geotextiles be recycled?

- Yes, geotextiles can be recycled. They are typically made of synthetic materials such as polyester or polypropylene, which can be melted down and processed into new products. Recycling geotextiles helps to reduce waste and minimize the environmental impact of these materials.

- Q: Geotextile what role

- Geotextile is a new type of building materials, raw materials are polyester, acrylic, nylon and other polymer polymer synthetic fiber.According to the manufacturing method is divided into: there are two types of textile and non-woven geotextile geotextile with anti- Filter, drainage, isolation, reinforcement, protection, sealing and other functions, it is compared with conventional masonry and concrete anti-seepage effect, with low investment, simple construction process, short duration, good anti-seepage effect, effective channels The use of high coefficient of the advantages of water conservancy project dam and slope protection, channel isolation, seepage; road, railway, airport runway foundation isolation, filter, drainage, slope, retaining wall and road reinforcement, drainage; Construction of the soft foundation treatment, beach embankment, harbor wharf and breakwater reinforcement, drainage; landfill, thermal power plant ash dam, concentrator tailing dam isolation, seepage; geotextile has been widely used in infrastructure construction , And gradually applied to a wider range of areas.

- Q: What are the advantages of using geotextiles in agriculture?

- Geotextiles offer several advantages in agriculture. Firstly, they help in soil reinforcement and stabilization, preventing erosion and soil loss. Secondly, they can act as a barrier, controlling the movement of water, nutrients, and chemicals, thereby enhancing soil fertility and reducing the risk of groundwater contamination. Additionally, geotextiles promote better root development and plant growth by providing a stable and well-drained environment. Lastly, they contribute to weed control, reducing the need for herbicides and manual labor. Overall, geotextiles serve as an effective and sustainable solution in agriculture, improving soil health, crop yield, and environmental sustainability.

Send your message to us

High-Performance Geotextile Grid Road Building Constructive Felt Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords