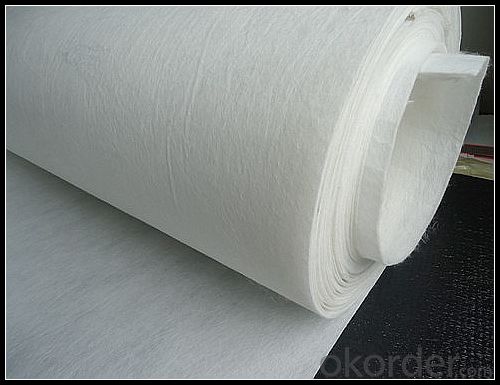

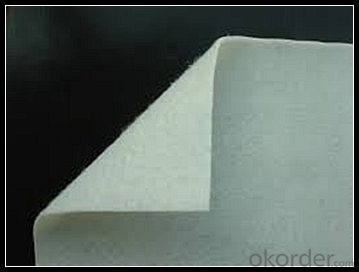

500g Basal Geotextile Nonwoven Road Building Constructive Felt Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Color:

White, Black, etc

Application:

Water Conservancy

Material:

PP(polypropylene) PET (polyester)

Certificate:

CE/ISO9001

Break Elongation:

25%~100%

Tensile Strength:

from 2.5 KN/m to 25KN/m

Nonwoven Geotextile

Geosynthetics are described or characterized as civil engineering materials that are intended for use with geological components like so rock or any other civil engineering associated materials to enhance or transform its behaviour, bringing out revolutions advantages in abundant area. They are porous textile materials of Non woven, woven or knitted. Their rise development for the period of the last 15 years has been nothing short of overwhelming and remarkable.Geosynthetics are up to date and modern construction products that can be utilized in transportation (rural roads, national state highways, seaports, airports).

Detailed Images

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: A creek next to our property is eating away the embankment and an engineer suggested using the sand in the creek bed.. wrapping it up in geotextile fabric in the form of a burrito but he did mnot mention how to fasten them shut..any ideas or experience with erosion control out there?

- Get some tie wire or baling wire. It's a soft wire used for tying reinforcing steel together or for baling straw. You could also use plastic cable ties.

- Q: Can geotextiles be used in wastewater treatment applications?

- Yes, geotextiles can be used in wastewater treatment applications. They are commonly used in filtration systems to separate solids from liquids and provide support for various treatment processes. Geotextiles can enhance the efficiency of wastewater treatment by improving filtration, reducing clogging, and increasing overall system performance.

- Q: Are geotextiles suitable for use in geogrid reinforced slopes?

- Yes, geotextiles are suitable for use in geogrid reinforced slopes. Geotextiles are often used as a separation and filtration layer in geogrid reinforced slopes to prevent the mixing of soil layers and ensure proper drainage, stability, and reinforcement. They help in distributing loads and reducing soil erosion, making them a valuable component in geogrid reinforced slopes.

- Q: What are the factors to consider when designing with geotextiles?

- When designing with geotextiles, there are several factors that need to be considered. These include the specific application or purpose of the geotextile, the physical and mechanical properties of the geotextile, the site conditions and environmental factors, the installation methods and techniques, and the long-term performance and durability requirements. Additionally, factors like cost, availability, and compatibility with other materials should also be taken into account during the design process.

- Q: What is the consequence of the geotextile of the ground floor

- What are the consequences of what can not be finalized, the first roof of the waterproof layer and waterproof protective layer is very important, this is the first barrier, imagine, now many of the green plants are large trees, grow 10 years or even 20 years After the roots will be very developed, think about how the pine trees on the tenacious know their strength, coupled with long-term erosion by the water, the concrete layer will gradually lose its ideal performance, barrier layer and drainage board will certainly be better To protect the role and drainage. So to speak, long-term vision of the words must be solidly do every layer, only focus on economic interests and short-term effects, then, within a few years will not be any problem.

- Q: Can geotextiles be used in coastal revetment projects?

- Yes, geotextiles can be used in coastal revetment projects. Geotextiles are often employed as a protective layer or a filter between the revetment structure and the native soil, helping to prevent erosion and stabilize the coastline. They can enhance the overall stability and longevity of coastal revetments while allowing for proper water drainage.

- Q: How do geotextiles help with soil separation and stabilization?

- Geotextiles help with soil separation by acting as a barrier that prevents the mixing of different soil layers. They also aid in soil stabilization by providing reinforcement and strength to the soil, reducing erosion and maintaining the stability of the ground.

- Q: Why do you shop the geotextile during the construction of the road

- Huazhi geotechnical materials manufacturers to answer

- Q: Can geotextiles be used in shoreline restoration projects?

- Yes, geotextiles can be used in shoreline restoration projects. Geotextiles are commonly used to stabilize and reinforce shorelines by preventing erosion, promoting vegetation growth, and improving water filtration. They can be installed as a barrier between the shoreline and the water, or used as a base layer beneath rocks or other materials to provide added strength and stability. Overall, geotextiles are an effective solution for shoreline restoration projects.

- Q: How are geotextiles used in landfill construction?

- Geotextiles are used in landfill construction as a protective barrier between the waste material and the underlying soil. They help to prevent the contamination of soil and groundwater by acting as a filter, allowing for the drainage of liquids while retaining the solid waste. Geotextiles also reinforce the stability and integrity of the landfill by providing additional strength and preventing erosion.

Send your message to us

500g Basal Geotextile Nonwoven Road Building Constructive Felt Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords